CCI Thermal Technologies G Series - Industrial Infrared Gas Catalytic Heater User Manual

Page 3

3

Separate Installation and Operation Instructions are available for industrial heating applications.

TABLE 4 - HEATER CLEARANCE

D - Radient Surface

C - Sides

A - Top

B - Bottom

Radient

Surface

Position

Heaters Up

To 12,000

Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000

Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000

Btu/hr

(17.572 kW)

All Heaters

Up To

60,000

Btu/hr

(17.572 kW)

Heaters Up

To 12,000

Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000

Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000

Btu/hr

(17.572 kW)

Heaters Up

To 12,000

Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000

Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000

Btu/hr

(17.572 kW)

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

Vertical (0°)

28

711

42

1067

60

1524

12

305

18

457

18

457

42

1067

7

178

12

305

18

457

0-45° up

28

711

42

1067

60

1524

12

305

18

457

32

813

54

1372

0

0

12

305

18

457

0-45° down

28

711

42

1067

60

1524

12

305

18

457

18

457

18

457

22

559

24

610

42

1067

5.3

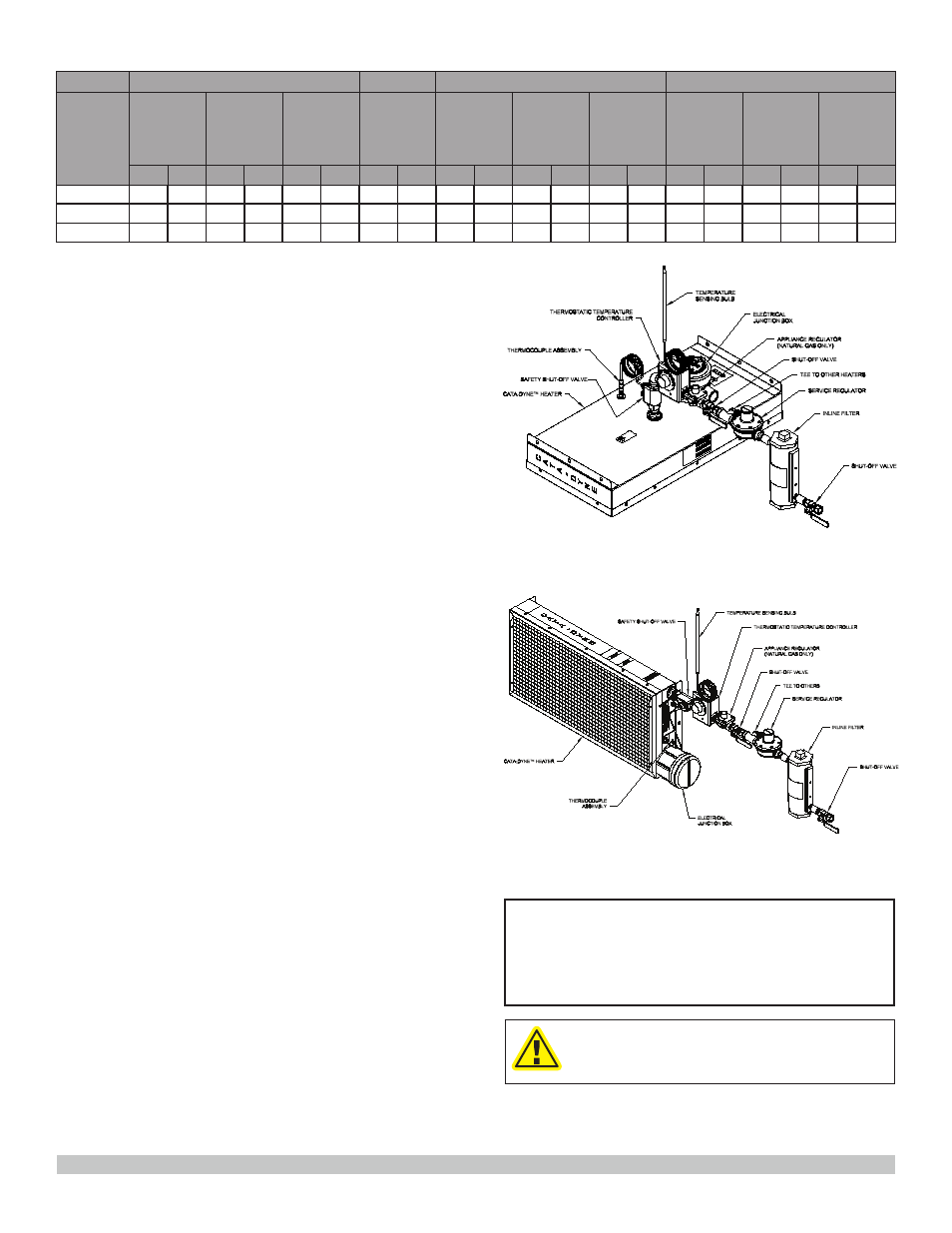

Piping

(i) A main shut-off valve must be installed

upstream of all auxiliary heater controls.

(ii) The 100% safety shut-off valve (SSOV)

and appliance regulator (natural gas

heaters only) must be installed in the

upright position (horizontally).

(iii) The thermostatic temperature controller

should be installed with the dial shaft in

the horizontal position.

(iv) The maximum inlet pressure to the

100% safety shut-off valve, thermostatic

temperature control and appliance

regulator is 1/2 psi (3.4 kPa). If the

inlet pressure is higher than this, a low

pressure service regulator must be

installed upstream of these components.

(v) The maximum inlet pressure to the low

pressure service regulator (available

from CCI Thermal) is 250 psi (1.7 MPa).

If the inlet pressure is higher than this,

a high-pressure regulator must be

installed upstream.

(vi) All components should be installed as

indicated in

FIGURE 2 (WX and BX

models) or FIGURE 3 (MKII model).

5.4

Electrical

(i) All wiring is to be installed in accordance

with the latest revisions of the Canadian

Electrical Code (CEC)/National Electrical

Code (NEC) and any applicable local codes.

(ii) It is desirable to install an indicating light

on all starting systems. This will reduce

the possibility of the power being left on

once the heater is started, which can

severely reduce the lifespan of the heater.

(iii) Ground connections for 120V and higher

voltage heaters are required as indicated

in FIGURE 4 and FIGURE 5.

(iv) The number of terminals in the junction

box can be two of four depending

on the number of elements used in

the fabrication of the heater. All MKII

models incorporate a single element

and therefore have only two terminals.

The connection procedure for the

different combinations is as described in

FIGURE 4 and FIGURE 5.

FIGURE 2 - TYPICAL NATURAL GAS INSTALLATION -

WX & BX MODELS ONLY

FIGURE 3 - TYPICAL NATURAL GAS INSTALLATION -

MKII MODEL ONLY

NOTE:

Gas appliance regulators and manual shut off valves

are required standard components for all CSA approved

heaters; they are available as optional accessories for

FM approved heaters.

CAUTION

INSTALL MKII SERIES HEATERS WITH

CONTROLS ON SIDES OR BOTTOM OF

HEATER ONLY.