Viking Pump TSM630.1: H-LL Universal Seal User Manual

Page 6

SECTION TSM 630.1

ISSUE

F

PAGE 6 OF 14

3. Move rotary member so setscrews are directly below seal

access holes on side of bracket. Tighten all setscrews

securely to shaft. Some seals are equipped with holding

clips which compress the seal springs. Remove holding

clips to release springs after seal is installed on shaft.

4. FOR “O-RING” GASKET TYPE MECHANICAL SEAL

SEAT: Lubricate outer diameter of O-Ring seal gasket

with oil. Flush sealing faces of both rotary member

and seal seat with oil and press seal seat in to bore

until back, unlapped face, is flush with bore. Install

seal holder, capscrews, and nuts and tighten securely.

Remove tapered installation sleeve.

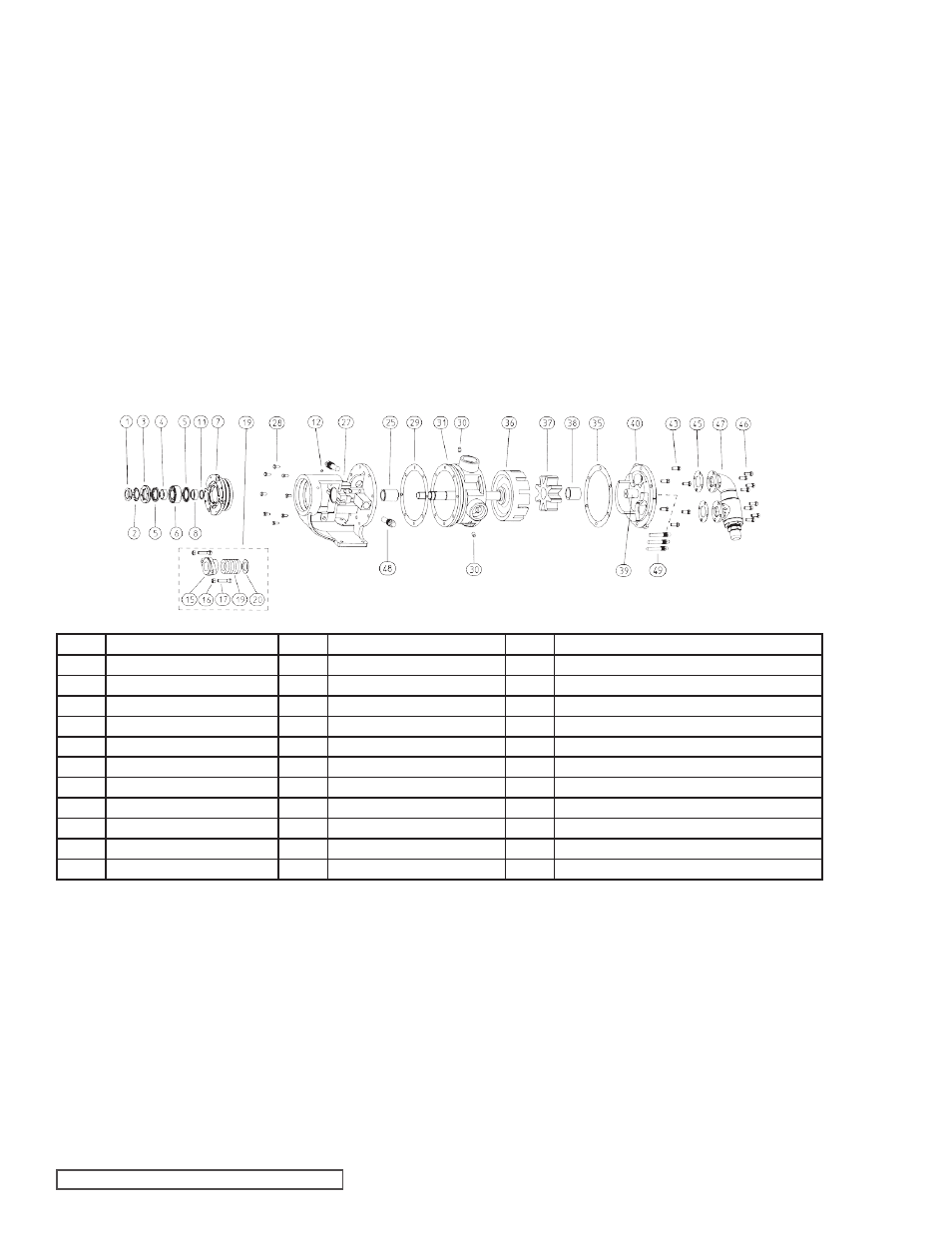

ITEM

NAME OF PART

ITEM

NAME OF PART

ITEM

NAME OF PART

1

Locknut

16

Packing Gland Nut

36

Rotor and Shaft Assembly

2

Lockwasher

17

Packing Gland Capscrew

37

Idler and Bushing Assembly

3

End Cap

19

Packing

38

Idler Bushing

4

Bearing Spacer Collar (Outer)

20

Packing Retainer Washer

39

Idler Pin

5

Lip Seal

25

Bracket Bushing

40

Head and Idler Pin Assembly

6

Ball Bearing

27

Bracket and Bushing Assembly

43

Capscrew for Head

7

Bearing Housing

28

Capscrew for Bracket

45

Relief Valve Gasket

8

Bearing Spacer Collar (Inner)

29

Bracket Gasket

46

Capscrew for Valve

11

Ring, Half Round (Not H, HL)

30

Pipe Plug

47

Internal Relief Valve

12

Grease Fitting

31

Casing (Tapped or Flanged)

48

Heater Cartridges for Bracket (124E Pumps Only)

15

Packing Gland

35

Head Gasket

49*

Heater Cartridges for Head (124E Pumps Only)

REPAIR: MODELS H, HL, K, KK, L, LQ AND LL

PACKED PUMPS

FOR “CLAMPED-IN” TYPE MECHANICAL SEAL

SEAT: Flush sealing faces of both rotary member and

seal seat with oil and install seal seat and seat gasket

over end of shaft against machined bracket face. Install

other seal gasket, seal holder, capscrews, and nuts and

tighten securely. Remove tapered installation sleeve.

5. Connect flush line or vent stuffing box for seals without

flush line until liquid is present on start up.

NOTE: For maximum seal life, flush line should be used.

EXPLODED VIEW PARTS FOR SERIES 124E/EH, 224A/AE/AH, 223A, 226A, AND 227A MODELS

* The number of Heater Cartridges for Head varies by pump size.

See Table 2 on Page 13 for the number required by pump size.