Pressure relief valve instructions, Disassembly, Assembly important – Viking Pump TSM430: HL-N 34/434 User Manual

Page 8

SECTION TSM 430

ISSUE

G

PAGE 8 OF 9

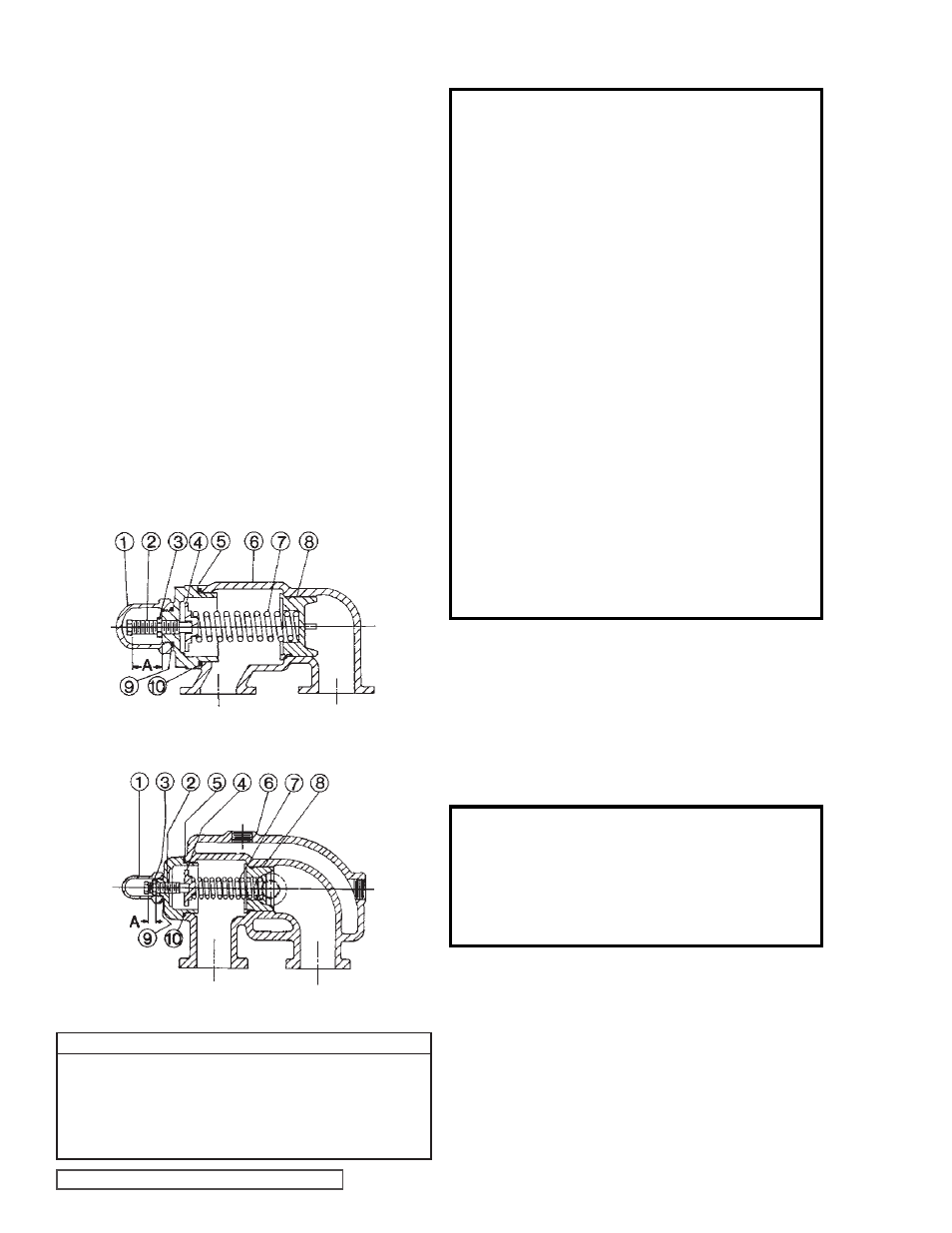

PRESSURE RELIEF VALVE

INSTRUCTIONS

FIGURE 11

PLAIN VALVE

VALVE - LIST OF PARTS

1. Valve Cap

6. Valve Body

2. Adjusting Screw

7. Valve Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

10 Bonnet Gasket

Series 34 and 434 jacketed pumps may be furnished with

a relief valve head and a plain or jacketed relief valve as

illustrated in

Figures 10 and 11.

FIGURE 11

JACKETED VALVE

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

DISASSEMBLY

7. When converting an existing installation to a mechanical

seal, special attention must be placed on the condition

of the pump. All pumps should be inspected to make

sure the rotor shaft is in good condition. Any shaft wear

due to packing will result in mechanical seal leakage.

In general, the rotor and shaft assembly should be

replaced. N size pumps can use the same rotor bearing

sleeve assembly without modification. Outboard face

of this assembly will need to be cleaned to make sure

there is a good surface for the mechanical seal to seal

against.

8. Most asphalt pumps are V-Belt driven. Packing is quite

tolerant of any misalignment but mechanical seals are

not. Make sure sheaves are aligned properly

(see TSM

000) and that the rotor shaft is properly supported with a

pillow block bearing. It is also important to make sure the

mechanical seal is properly aligned with the rotor shaft.

This is done at the time of seal installation. Be sure to

recheck alignment when the rotor shaft is inserted in the

pillow block bearing.

ASSEMBLY

IMPORTANT

In ordering parts for relief valve on head, always be sure

to give Model and Serial Number of pump as it appears on

nameplate and the name of the part wanted. When ordering

springs, be sure to give the pressure setting desired.

Follow the procedure outlined under Disassembly in reverse

order.

If valve is removed for repairs, be sure to replace in same

position. The valve cap should point towards the suction

port.

CAUTION !

Before starting the pump, be sure all drive

equipment guards are in place.

Failure to properly mount guards may

result in serious injury or death.