Assembly – Viking Pump TSM430: HL-N 34/434 User Manual

Page 7

PSII® is a registered trademark of FlowServ.

SECTION TSM 430

ISSUE

G

PAGE 7 OF 9

6. THRUST WASHERS: Rotor thrust washer and rotor

bearing sleeve thrust washer – used in Q, M and N size

pumps should be removed, examined for excessive

wear and replaced if necessary. These thrust washers

are located on the hub of the rotor and the casing end of

rotor bearing sleeve.

7. If the rotor-bearing sleeve, casing or idler bushing shows

signs of wear it should be replaced. All parts should be

checked for wear before the pump is put together. When

making major repairs, such as replacing a rotor and shaft,

it is usually considered advisable to also install a new

head and idler. When making minor repairs, where only

an idler bushing and idler pin are required, other new

parts are usually not necessary. When all the necessary

parts are available, the pump can be assembled.

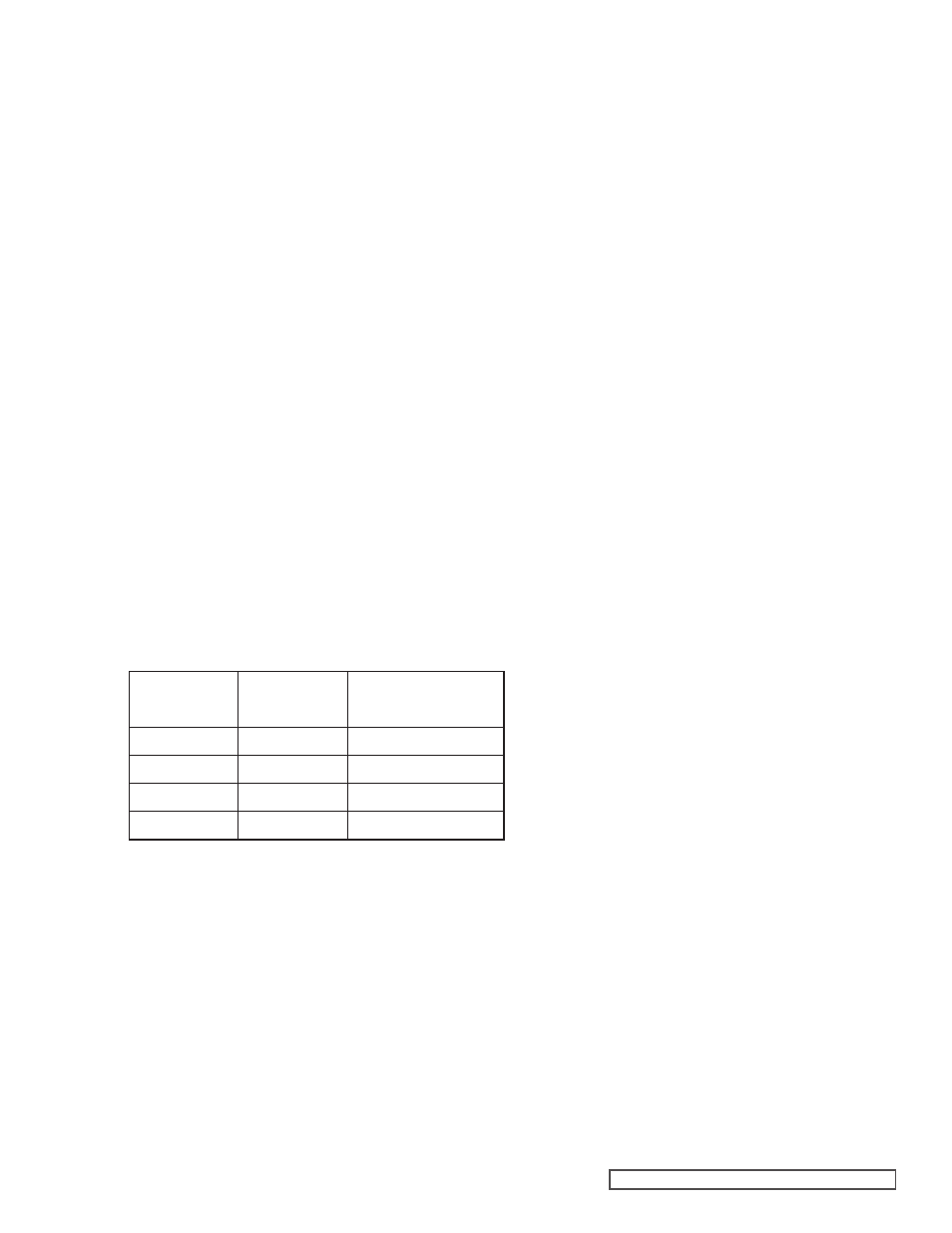

PUMP

MODELS

NORMAL

AMOUNT USED

(INCH)

ONE SET OF GASKETS

CONSISTS OF THE

FOLLOWING

HL 34 & 434

.010” - .020”

1 - .005” , 2 - .007”

KK 34 & 434

.015” - .025”

2 - .007” , 1 - .015”

LQ 34 & 434

.025” - .035”

1 - .015” , 2 - .006”

Q, M, N 34 & 434

.020” - .035”

2 - .015” , 1 - .006”

ASSEMBLY

1. Thrust washers used in Q, M and N size pumps should

be assembled on the rotor hub and rotor-bearing sleeve.

Put the plain washer on the two locating pins on the rotor

hub. Put the grooved face washer on the pins on the

rotor-bearing sleeve with the grooved face toward the

rotor.

2. Remove all burrs and rough surfaces from the rotor and

shaft and assemble in the casing. Lubricate the rotor

shaft and bushing with grease and start the shaft through

the rotor bearing sleeve or casing bushing. Slowly turn

the rotor and push it into the casing as far as it will go.

3. Place the head gaskets on the head. The proper amount

of gaskets should be used to provide the necessary

end clearance within the pump so it turns freely with no

appreciable endplay. The Gasket Table (

below gives

the normal amount of gaskets used on each pump.

4. Lubricate the idler pin with lube oil and place the idler

and bushing assembly on the idler pin.

5. The head can now be assembled on the pump. Make

sure it is installed in the correct position

See Disassembly

Step 1 (Note), page 6. Tilt the top of the head away

from the pump slightly until the crescent enters the

inside diameter of the rotor and rotate the idler until its

teeth mesh with the rotor teeth. Do not damage the

head gaskets. Tighten the head capscrews or nuts and

then check the end clearance. If the pump shaft cannot

be rotated, more gaskets must be added. If, however,

the pump has any noticeable end play, remove enough

gaskets so the pump has no appreciable end play but

still turns freely.

PACKED PUMPS

6. Pack the pump. It is good practice to install a set of

new packing. The pump should be packed with packing

suitable for the liquid being pumped.

Cut the packing into individual rings that wrap exactly

around the shaft. Install and seat each ring one at a

time, staggering the ring joints from one side of the shaft

to the other. Lubricate the packing rings with oil, grease

or graphite to aid in assembly. A length of pipe or tubing

will help in seating the packing rings.

7. Install the packing gland and nuts. The gland must

enter the stuffing box at least one-eighth of an inch after

tightening the packing gland nuts. Be sure the packing

does not wedge between the stuffing box and the gland,

as this may split the stuffing box.

MECHANICAL SEAL PUMPS

(X-100 & X-200)

6. Make sure the shaft is clean and free of any nicks or

burrs. Lubricate the shaft with lube oil and slide the

mechanical seal in place.

7. Place flat washers and lock washers on the studs then

thread on the retaining nuts. Tighten the nuts evenly

to secure the mechanical seal to the stuffing box face.

Make sure the seal setting clips are in place and tighten

the drive setscrews to the shaft. Leave the setting clips

in place until after the pump is installed on the drive unit.

Be sure and remove the clips before start up.

(PSII SEAL®)

6. Make sure the shaft is clean and free of any nicks or

burrs. Lubricate the shaft with lube oil and slide the

mechanical seal in place.

7. Rotate the seal installation tabs 90 degrees so they

point towards the seal sleeve. Adjust the position of the

seal so the sleeve is evenly spaced between the tabs.

Place flat washers and lock washers on the studs then

thread on the retaining nuts. Tighten the nuts evenly to

secure the seal to the stuffing box face. Tighten the drive

setscrews to the shaft. Using a feeler gage, make sure

there is still an equal space between the sleeve and the

retaining tabs. Readjust if necessary. Leave the seal

installation tabs in position until the pump is installed on

the drive unit and properly aligned. Rotate the tabs 90

degrees before pump start up.

MECHANICAL SEAL NOTES

1. Vent air from stuffing box before start up. The seal may

fail prematurely if this is not done.

2. Preheat seal prior to introducing hot product.

3. Use of low pressure (2 – 4 psi) continuous flow steam

quench on the atmospheric side is recommended.

Failure to use a steam quench could result in premature

seal failure.

4. For double seals, pressurize seal chamber before

startup.

5. Do not start pump until it is fully heated. Mechanical

seal will fail almost instantly if hard product is in the seal

chamber.

6. Do not use the PSII® cartridge lip seal for filled asphalt

or any product containing abrasives.

FIGURE 9

GASKET TABLE