Mounting, Alignment, Piping/hose – Viking Pump TSM350 HG-08/HG-10 Helical Gear Pumps User Manual

Page 2

SECTION TSM

350

ISSUE

A

PAGE 2 OF 10

MOUNTING

1. Surfaces to which the pump mounts must be clean, flat and free of dings and burrs.

2. Use ISO Class 8.8 or better capscrews to mount pump.

3. The 4 mounting capscrews for the HG-08 pumps must have a minimum of 12 millimeters

thread engagement, and must be evenly torqued to 22-24 Nm (16-18 ft lbs).

4. The 4 mounting capscrews for the HG-10 pumps must have a minimum of 18

millimeters thread engagement, and be evenly torqued to 79-83 Nm (56-62 ft lbs).

5. Standard HG Series pumps are designed to be used with jaw type couplings that do not

induce axial thrust on the pump shaft. If an improper type of coupling is used, internal

damage may result.

6. Do not strike or press the pump drive coupling to install. Internal pump damage will

result. If the coupling does not slide onto the shaft, inspect the coupling, shaft and

key for nicks or burrs and remove.

7. Once the pump has been mounted and the coupling installed, it is recommended to put

lube oil into the suction port and turn the pump by hand to make sure it turns freely.

Alignment

Check alignment after mounting.

1. Make sure that the driver has been “locked out” so that it cannot be inadvertently

started while checking alignment.

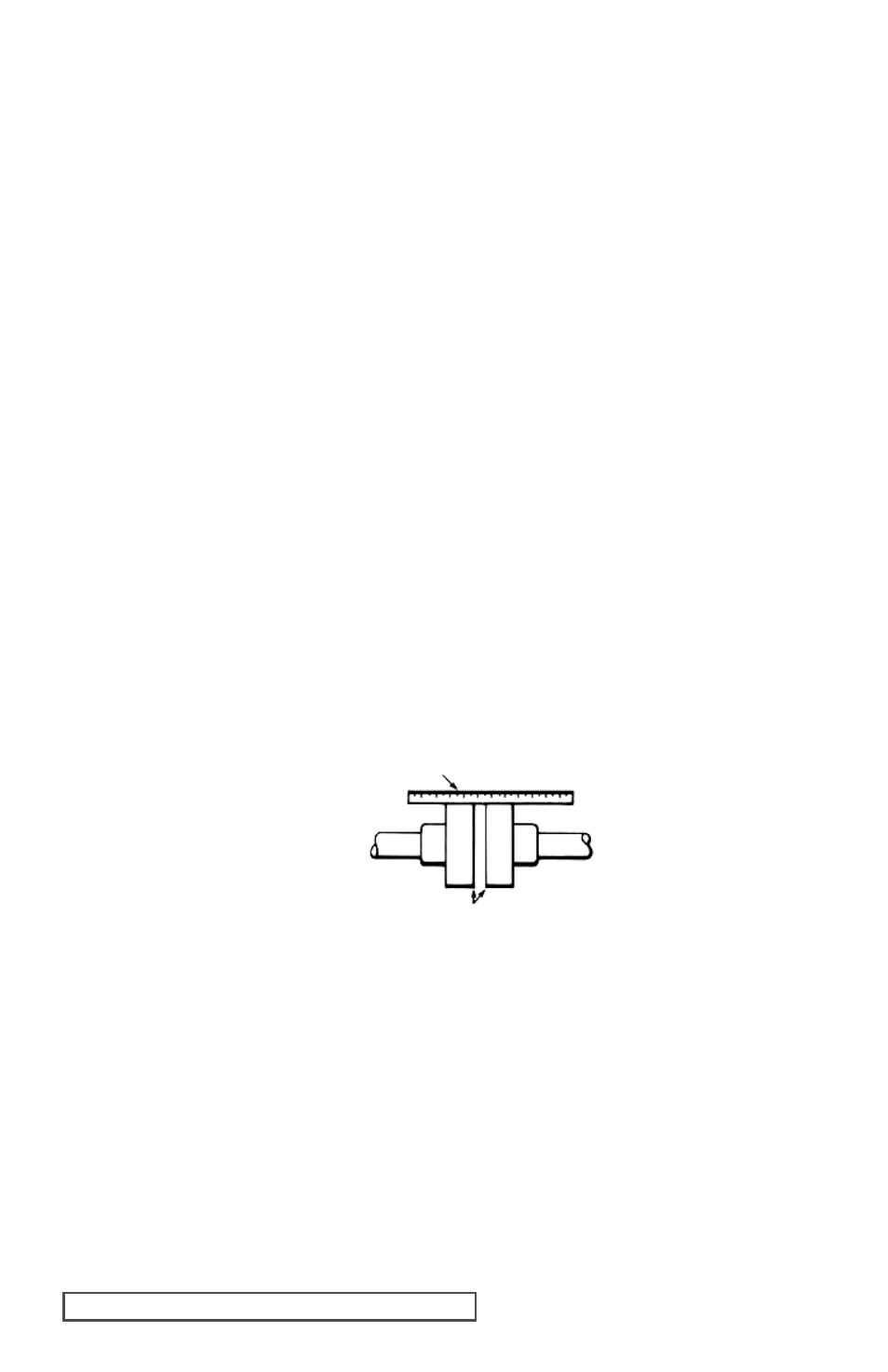

2. If the unit has a flexible coupling, remove any coupling guards or covers and check

alignment of coupling halves. A straight edge (piece of key stock will work) across the

coupling must rest evenly on both rims at the top, bottom and sides. See Figure 3.

3. Make a final check on alignment after the piping is hooked up.

USE STRAIGHT EDGE. THESE

SURFACES MUST

BE PARALLEL

CHECK WIDTH BETWEEN THESE SURFACES WITH INSIDE CALIPERS OR FEELER

GAUGE TO BE CERTAIN THE FACES ARE EQUAL DISTANCE APART AND PARALLEL.

FIGURE 3

Piping/Hose

The cause of many pumping problems can be traced to the suction piping. It should always be

as large in diameter and as short in length as possible.

Before starting the layout and installation of your piping system, consider the following points:

1. Never use piping smaller than the pump port connections. Piping larger in diameter than

the port connection is sometimes required to reduce friction losses.