Viking Pump TSM343.1: Vi-Corr Mag Drive User Manual

Page 4

TSM 343.1 ISSUE D PAGE 4 OF 13

2.

Check Pump alignment (See page 3).

3.

Check piping to be sure there is no strain on the pump

casing.

4.

Rotate the pump shaft by hand to be sure it turns freely.

55. Motor has been jogged and is running in the correct

direction. Refer to "General" on page 2.

6. Pressure relief valve is installed properly.

7. Suction piping is connected and tight, and valves are

open.

8. Make sure discharge piping is connected and tight,

valves are open and, and end of shaft is below liquid

level.

9. All guards are in place.

10. The above checklist is a general guideline to be used

prior to starting pump. Since Viking pump cannot foresee

every application for our product and possible system

design, final responsibility is with the user. The pump

must be utilized within the catalog specifications and the

pump system must be designed to provide safe working

conditions.

Push the "start" button. Pump should begin to deliver liquid

within 15 seconds!

If the pump does not deliver liquid, push the stop button.

Do

not run the pump without liquid flow longer than 30

seconds because pump or coupling could be damaged

or ruined.

Review steps just outlined. Consider what suction and

discharge gauges indicate. If everything appears in order, put

more liquid in the pump suction port. See item 6 on page 3.

Push the start button. If nothing happens within 30 seconds,

stop the pump. The pump is not a compressor and will not

build up much air pressure. It may be necessary to vent the

discharge line until liquid begins to flow. Use a safe venting

procedure especially when handling hazardous liquids.

If the pump still does not deliver liquid, consider one or more

of the following:

1. Suction line air leaks; vacuum gauge reading should help

determine if this is the problem.

2. End of suction pipe not submerged deep enough in liquid.

3. Suction lift is too great or suction piping is too small.

4. Liquid is vaporizing in the suction line before it gets to the

pump.

5. Magnetic coupling is decoupling for some reason.

If after consideration of these points, the pump still does not

deliver liquid, review all points given under

START UP and

read through the

TROUBLESHOOTING guide and try again.

If pump still will not deliver liquid, contact your Viking Pump

supplier.

SUGGESTED REPAIR TOOLS: The following are required

to properly repair a RP Series Mag Drive pump. The tools are

in addition to standard mechanics tools such as open end

wrenches, pliers, screw drivers, etc. Most of the items can be

obtained from an industrial supply house.

1. Soft face hammer

2. Allen wrenches

3. Internal snap ring pliers (for bearing carriers only) 2-810-

029-047-999 (Truarc No. 0500)

4. External snap ring pliers 2-810-029-375 (Truarc No. 0400)

4. Arbor press

5. Torque wrench

DISASSEMBLY Of MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1. Read all of the instructions before proceeding with

disassembly of the coupling and/or pump. Remove

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace -

especially the encapsulated O-rings. Follow instructions

in

ASSEMBLY for installation of a new Teflon®

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

bearing carrier. Loosen setscrews in outer magnet

assembly to pull assembly off shaft.

PAGE 4 Of 13

ISSUE

C

SECTION TSM 343.1

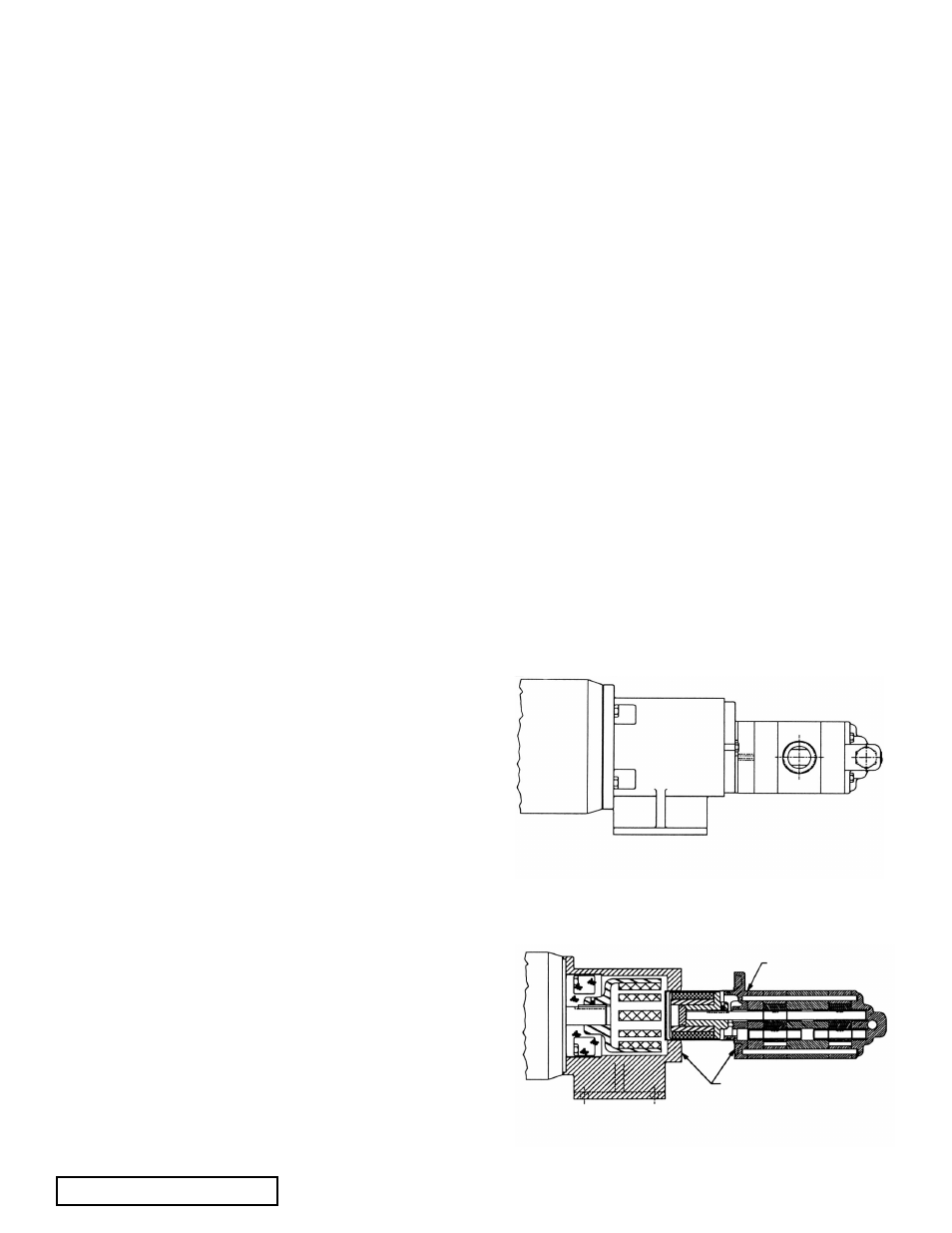

fIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE fINGERS

HERE AT ANY TIME

fIGURE 6

Typical Pump Removal from Coupling Bracket

2.

Check Pump alignment (See page 3).

3.

Check piping to be sure there is no strain on the pump

casing.

4.

Rotate the pump shaft by hand to be sure it turns freely.

55. Motor has been jogged and is running in the correct

direction. Refer to "General" on page 2.

6. Pressure relief valve is installed properly.

7. Suction piping is connected and tight, and valves are

open.

8. Make sure discharge piping is connected and tight,

valves are open and, and end of shaft is below liquid

level.

9. All guards are in place.

10. The above checklist is a general guideline to be used

prior to starting pump. Since Viking pump cannot foresee

every application for our product and possible system

design, final responsibility is with the user. The pump

must be utilized within the catalog specifications and the

pump system must be designed to provide safe working

conditions.

Push the "start" button. Pump should begin to deliver liquid

within 15 seconds!

If the pump does not deliver liquid, push the stop button.

Do

not run the pump without liquid flow longer than 30

seconds because pump or coupling could be damaged

or ruined.

Review steps just outlined. Consider what suction and

discharge gauges indicate. If everything appears in order, put

more liquid in the pump suction port. See item 6 on page 3.

Push the start button. If nothing happens within 30 seconds,

stop the pump. The pump is not a compressor and will not

build up much air pressure. It may be necessary to vent the

discharge line until liquid begins to flow. Use a safe venting

procedure especially when handling hazardous liquids.

If the pump still does not deliver liquid, consider one or more

of the following:

1. Suction line air leaks; vacuum gauge reading should help

determine if this is the problem.

2. End of suction pipe not submerged deep enough in liquid.

3. Suction lift is too great or suction piping is too small.

4. Liquid is vaporizing in the suction line before it gets to the

pump.

5. Magnetic coupling is decoupling for some reason.

If after consideration of these points, the pump still does not

deliver liquid, review all points given under

START UP and

read through the

TROUBLESHOOTING guide and try again.

If pump still will not deliver liquid, contact your Viking Pump

supplier.

SUGGESTED REPAIR TOOLS: The following are required

to properly repair a RP Series Mag Drive pump. The tools are

in addition to standard mechanics tools such as open end

wrenches, pliers, screw drivers, etc. Most of the items can be

obtained from an industrial supply house.

1. Soft face hammer

2. Allen wrenches

3. Internal snap ring pliers (for bearing carriers only) 2-810-

029-047-999 (Truarc No. 0500)

4. External snap ring pliers 2-810-029-375 (Truarc No. 0400)

4. Arbor press

5. Torque wrench

DISASSEMBLY Of MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1. Read all of the instructions before proceeding with

disassembly of the coupling and/or pump. Remove

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace -

especially the encapsulated O-rings. Follow instructions

in

ASSEMBLY for installation of a new Teflon®

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

bearing carrier. Loosen setscrews in outer magnet

assembly to pull assembly off shaft.

PAGE 4 Of 13

ISSUE

C

SECTION TSM 343.1

fIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE fINGERS

HERE AT ANY TIME

fIGURE 6

Typical Pump Removal from Coupling Bracket

2.

Check Pump alignment (See page 3).

3.

Check piping to be sure there is no strain on the pump

casing.

4.

Rotate the pump shaft by hand to be sure it turns freely.

55. Motor has been jogged and is running in the correct

direction. Refer to "General" on page 2.

6. Pressure relief valve is installed properly.

7. Suction piping is connected and tight, and valves are

open.

8. Make sure discharge piping is connected and tight,

valves are open and, and end of shaft is below liquid

level.

9. All guards are in place.

10. The above checklist is a general guideline to be used

prior to starting pump. Since Viking pump cannot foresee

every application for our product and possible system

design, final responsibility is with the user. The pump

must be utilized within the catalog specifications and the

pump system must be designed to provide safe working

conditions.

Push the "start" button. Pump should begin to deliver liquid

within 15 seconds!

If the pump does not deliver liquid, push the stop button.

Do

not run the pump without liquid flow longer than 30

seconds because pump or coupling could be damaged

or ruined.

Review steps just outlined. Consider what suction and

discharge gauges indicate. If everything appears in order, put

more liquid in the pump suction port. See item 6 on page 3.

Push the start button. If nothing happens within 30 seconds,

stop the pump. The pump is not a compressor and will not

build up much air pressure. It may be necessary to vent the

discharge line until liquid begins to flow. Use a safe venting

procedure especially when handling hazardous liquids.

If the pump still does not deliver liquid, consider one or more

of the following:

1. Suction line air leaks; vacuum gauge reading should help

determine if this is the problem.

2. End of suction pipe not submerged deep enough in liquid.

3. Suction lift is too great or suction piping is too small.

4. Liquid is vaporizing in the suction line before it gets to the

pump.

5. Magnetic coupling is decoupling for some reason.

If after consideration of these points, the pump still does not

deliver liquid, review all points given under

START UP and

read through the

TROUBLESHOOTING guide and try again.

If pump still will not deliver liquid, contact your Viking Pump

supplier.

SUGGESTED REPAIR TOOLS: The following are required

to properly repair a RP Series Mag Drive pump. The tools are

in addition to standard mechanics tools such as open end

wrenches, pliers, screw drivers, etc. Most of the items can be

obtained from an industrial supply house.

1. Soft face hammer

2. Allen wrenches

3. Internal snap ring pliers (for bearing carriers only) 2-810-

029-047-999 (Truarc No. 0500)

4. External snap ring pliers 2-810-029-375 (Truarc No. 0400)

4. Arbor press

5. Torque wrench

DISASSEMBLY Of MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1. Read all of the instructions before proceeding with

disassembly of the coupling and/or pump. Remove

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace -

especially the encapsulated O-rings. Follow instructions

in

ASSEMBLY for installation of a new Teflon®

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

bearing carrier. Loosen setscrews in outer magnet

assembly to pull assembly off shaft.

PAGE 4 Of 13

ISSUE

C

SECTION TSM 343.1

fIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE fINGERS

HERE AT ANY TIME

fIGURE 6

Typical Pump Removal from Coupling Bracket

5.

6.