Viking Pump TSM343.1: Vi-Corr Mag Drive User Manual

Page 10

TSM 343.1 ISSUE D PAGE 10 OF 13

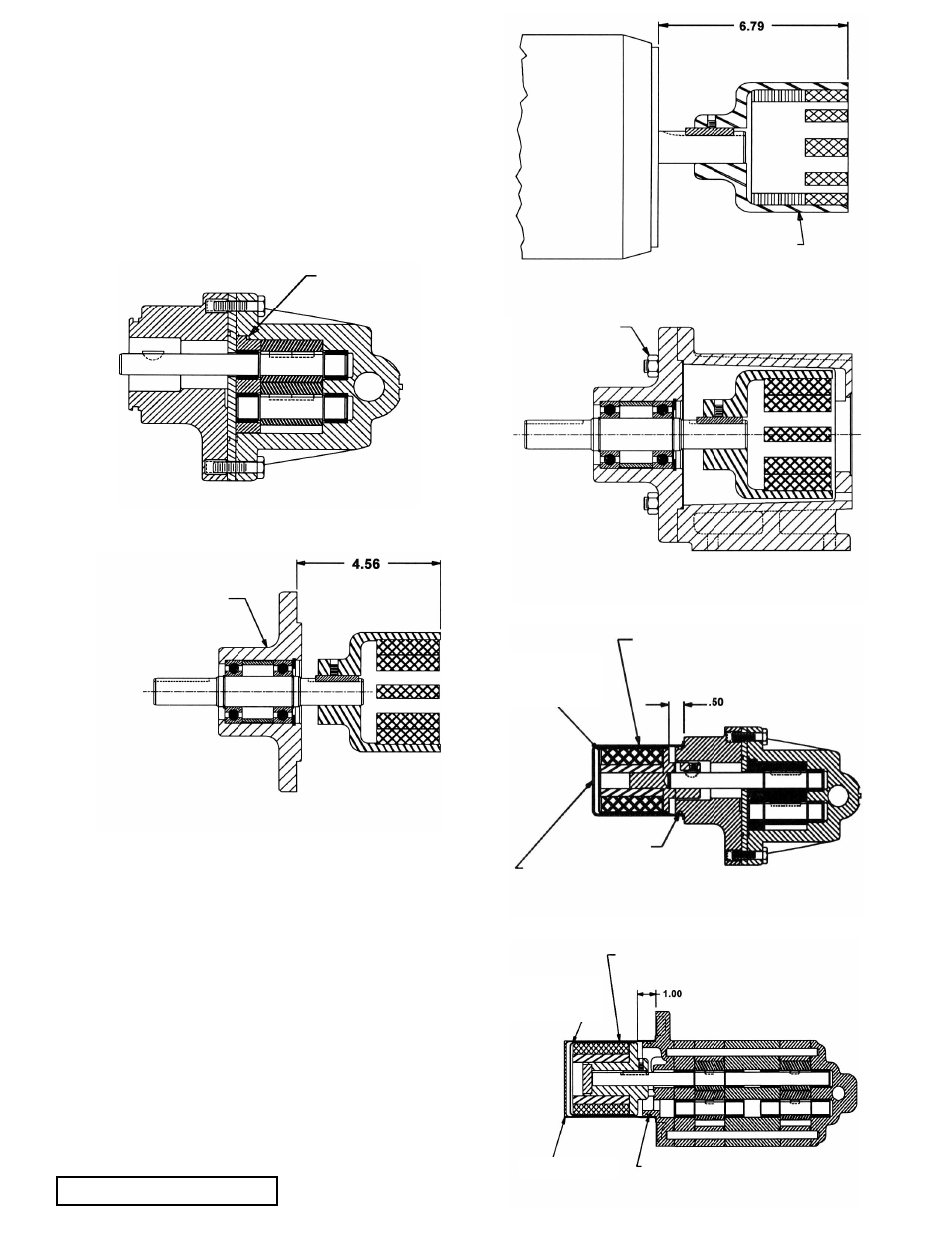

1. Inspect magnets for any metal objects attached to the

magnets. Remove any foreign material. Locate outer

magnet assembly per drawing. Reference point for MD-

A2 & MD -A8 is the back edge of the "C" face. See Figure

17. Apply loctite to setscrew threads and tighten both

setscrews onto motor or bearing carrier shaft. The

bearing carrier housing features a machined step on its

mounting flange, which is the reference point for setting

the position of the outer magnet.

2. Mount bracket to motor (or bearing carrier to footed

bracket) and secure with 4 capscrews. See Figure 18.

Reach in and rotate magnets by hand to make sure there

is no interference. If rubbing occurs, check dimensions

(see Figures 16 and 17) or contact factory.

3. Place inner magnet assembly onto pump shaft and set

according to figures. See Figure 19, or (See figure 20).

Place Loctite on threads of the two setscrews then

tighten. Check the dimension again, then turn the pump

over a couple of times to make sure it turns freely. Inspect

magnet and make sure it has not picked up any foreign

particles which could damage the pump. Make sure

bracket O-ring is in good condition and installed. Place

canister onto pump and press until canister is in contact

with pump bracket.

PAGE 10 Of 13

ISSUE

C

SECTION TSM 343.1

CASING NOTCH

fIGURE 15

BEARING CARRIER

ASSEMBLY

fIGURE 16

MD-A2 and MD-A8

STANDARD

"C" FACE

MOTOR

WITH 8-1/2"

RABBIT

OR

BEARING

CARRIER

OUTER MAGNET

ASSEMBLY

fIGURE 17

MD-B15 and MD-B40

CAPSCREW

(& NUT)

fIGURE 18

Coupling Bracket and Bearing Carrier for

MD-A2 and MD-A8

THIS SURFACE MUST BE FREE OF ANY

FOREIGN METAL PARTICLES PRIOR TO

ASSEMBLY INTO BRACKET

INNER

MAGNET

ASSEMBLY

CANISTER

STATIC O-RING

fIGURE 19

MD-A2 and MD-A8

THIS SURFACE MUST BE FREE OF ANY

FOREIGN METAL PARTICLES PRIOR TO

ASSEMBLY INTO BRACKET

INNER MAGNET

ASSEMBLY

CANISTER

STATIC O-RING

fIGURE 20

MD-B15 and MD-B40