Special pump designs, Pressure adjustment, Important – Viking Pump TSM320.1: C-FH 56/456 User Manual

Page 6: Pressure relief valve

SECTION TSM 320.1

ISSUE

E

PAGE 6 OF 7

The relief valve is a pressure device to protect the pump

and motor against excessive pressure. A pump without a

properly set pressure relief valve operating against a closed

discharge line could build up enough pressure to damage

the pump or motor.

The pressure setting is increased by turning the adjusting

screw in and decreased by turning the adjusting screw out.

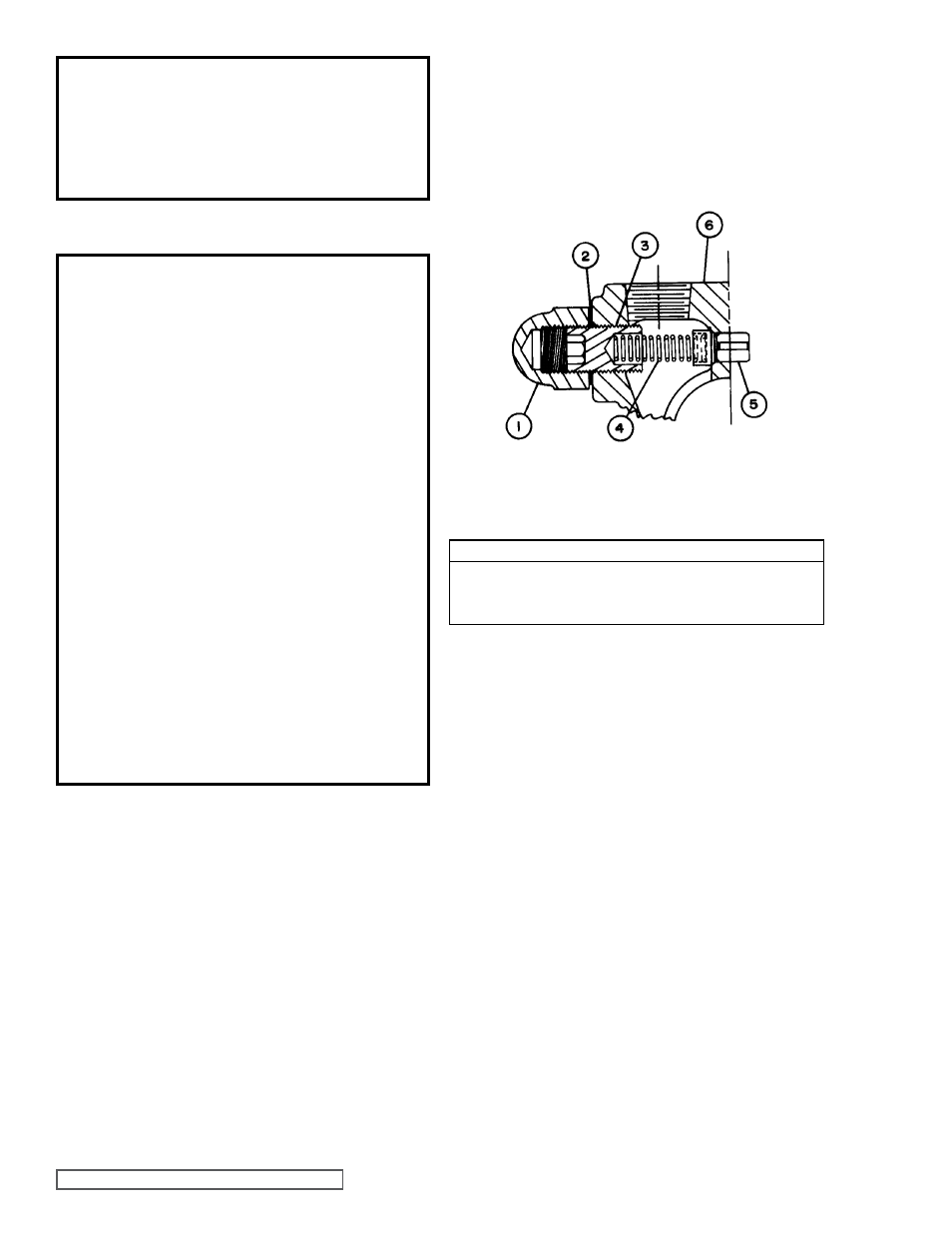

fIgURE 7

PRESSURE RELIEF VALVE - C, F, FH SIZE

VaLVE - LIST Of PaRTS

1.

Adjusting Screw Cap

4.

Spring

2.

Gasket for Cap

5.

Poppet

3.

Adjusting Screw

6.

Casing

DaNgER !

Before starting pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may

result in serious injury or death.

SPECIaL PUMP DESIgNS

Pumps furnished with a PTFE Mechanical seal require a

special rotor and shaft with drive pin installed for positive drive

of the rotating member. All other assembly and disassembly

instructions are the same.

PRESSURE aDJUSTMENT

DaNgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.

If a new spring is installed or if the pressure setting of the

pressure relief valve is to be changed from that which the

factory has set, the following instructions must be carefully

followed.

1. Carefully remove the valve cap, which covers the

adjusting screw.

Loosen the locknut, which locks the adjusting screw

so pressure setting will not change during operation of

the pump.

2. Install a pressure gauge in the discharge line for the

actual adjustment operation.

3. Turn the adjusting screw in to increase pressure and out

to decrease pressure.

4. With the discharge line closed at a point beyond the

pressure gauge, the gauge will show the maximum

pressure valve will allow while the pump is in operation.

IMPORTaNT

In ordering parts for the pressure relief valve, always give

the model number and serial number of the pump as it

appears on the nameplate and the name of the part wanted.

When ordering springs, be sure to give the pressure setting

desired.

PRESSURE RELIEf VaLVE