Assembly – Viking Pump TSM211: F-G 724/4724 User Manual

Page 6

SECTION TSM 211

ISSUE

D

PAGE 6 OF 8

ASSEMBLY

Remove the packing gland nut and seal seat. Inspect the

gaskets and the seal seat for wear. If the seal is to be re-

used, remove the rotating part of the mechanical seal as

follows: Remove the head and idler. Push the rotor and

shaft out until the outer end of the seal is approximately

flush with the first undercut on the shaft. Then draw rotor

shaft back into the casing and re-install head and idler on

the casing as shown in

figure 6. This has positioned the

rotary member beyond the casing. Now place the wire

spanner wrench (Provided in the instruction envelope)

under the rotary member as shown in

figure 6. Place

the seal seat on the rotary member and push downward

firmly. In this position install two installation clips on

rotary member (Provided in instruction envelope) 180º

apart before removing the rotary member of the seal.

The installation clips remove the load within the seal and

permits easier disassembly and re-assembly of the seal.

Again remove the head and idler permitting the rotor and

shaft to be removed.

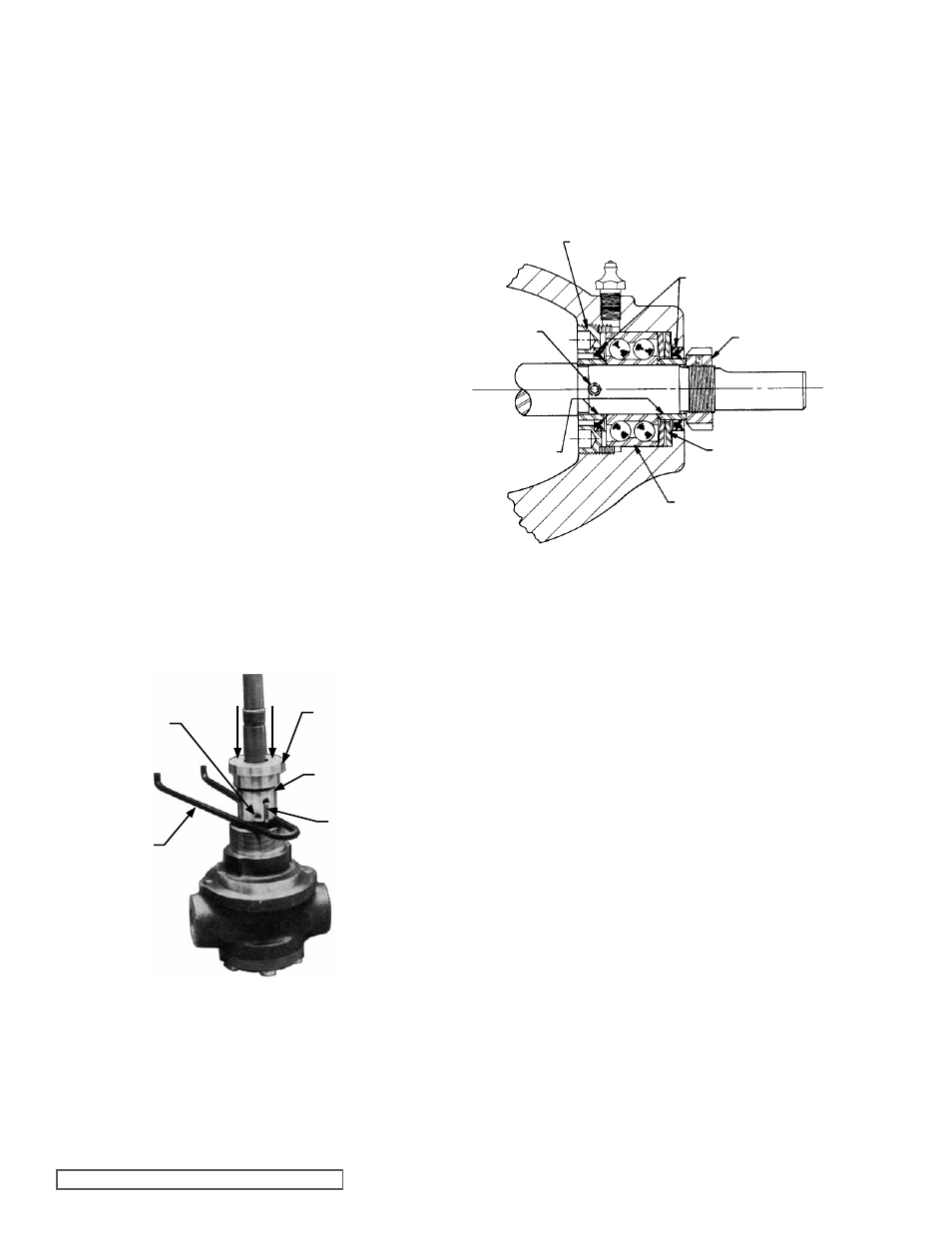

8. To remove the thrust bearing parts, figure 7, first loosen

the setscrew which locks the end cap. Next remove

the end cap allowing ball bearing and conical spring

washers to be removed. The bearings should be washed

thoroughly and examined. If there is any evidence of

wear or damage a new bearing should be used.

9. The casing should be examined for wear, particularly at

the I.D. between the port openings.

10. The casing bushing should be inspected and if it shows

signs of wear, should be replaced.

Examine the lipseals in the bracket and end cap. These

lipseals are important to this assembly and should be

replaced if not in first-class condition. They are a grease seal

for the ball bearing and also act as a shield to keep dirt or

debris from entering the bearing.

When installing new lipseals, be sure they are assembled

with the lips facing as shown in

figure 7.

If it is necessary to install a new carbon graphite bushing,

extreme care should be taken to prevent breaking, as it is a

brittle material and easily cracked. If cracked, this bushing will

quickly disintegrate. An arbor press should always be used in

installing carbon graphite bushings. Be sure the bushing is

started straight.

DO NOT STOP the pressing operation until

the bushing is in proper position. Starting and stopping this

operation may result in cracking.

1. Install the rotor and shaft. Be sure shaft is free from burrs

and foreign particles that might damage the bracket

bushing.

2. Place a head gasket on the head. With the idler on the

idler pin, put the head and idler on the pump and tighten

the capscrews evenly. Tilt the top of the head away from

the pump slightly until the crescent enters the inside

diameter of the rotor and rotate the idler until its teeth

mesh with the rotor teeth. This will help in putting the

head on the pump.

fIgURE 6

fIgURE 7

THRUST BEARINg AREA CROSS SECTION

END CAP

LOCKNUT

BEARINg

SPACERS (2)

SETSCREW

DOUBLE ROW

BALL BEARINg

CONICAL

SPRINg

WASHERS (2)

LIPSEALS (2)

SET SCREWS

SEAL SEAT

CLIPS

ROTARY

MEMBER

SPANNER

WRENCH