Disassembly – Viking Pump TSM211: F-G 724/4724 User Manual

Page 5

SECTION TSM 211

ISSUE

D

PAGE 5 OF 8

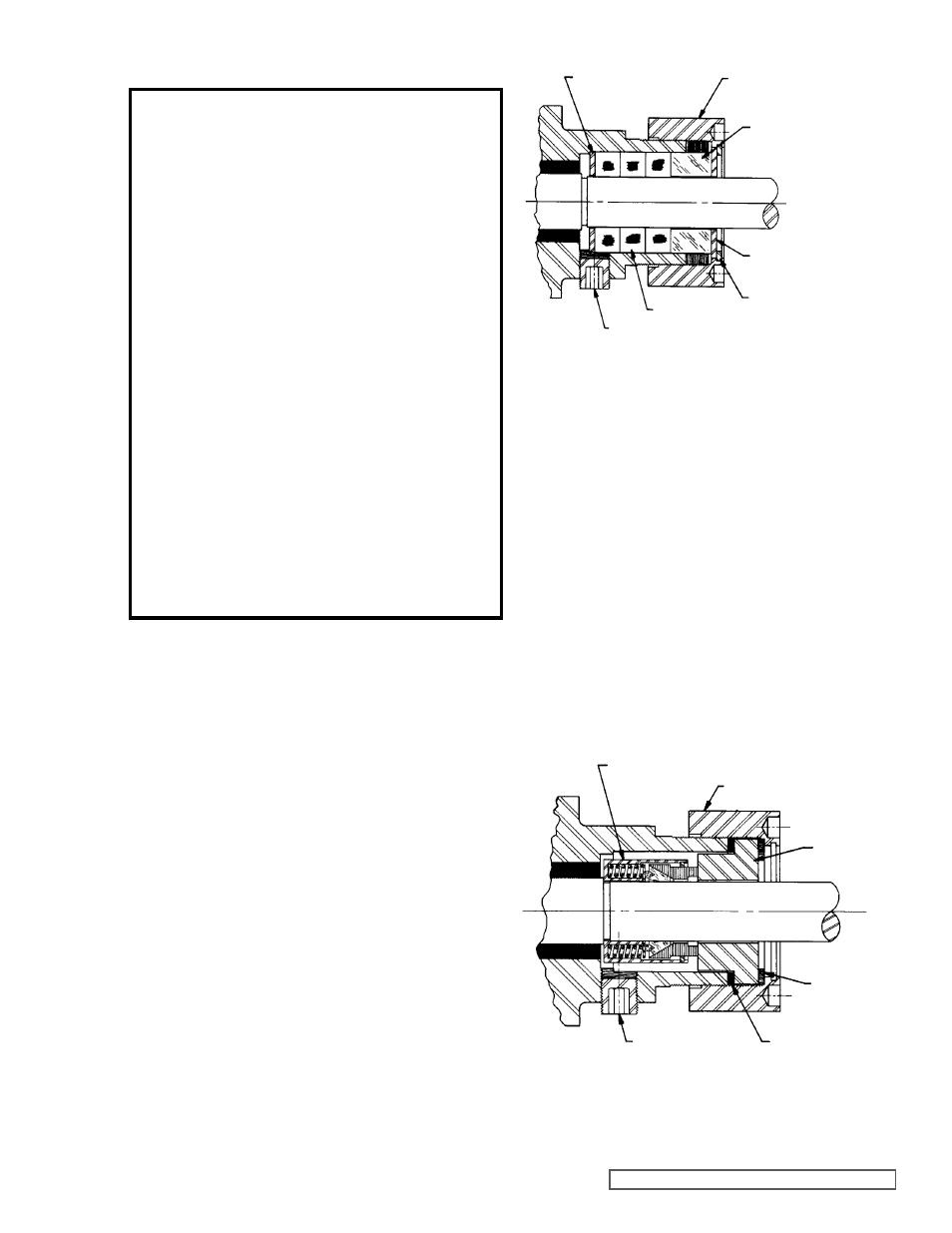

DISASSEMBLY

1. CAUTION: When the head is being removed from the

pump

(See figure 2), the idler usually stays on the

idler pin, but will fall off if the inside of the head is tilted

downward. A fall on a hard surface can damage the idler.

If the idler should fall, check carefully and file or stone all

nicked or rough places before reassembly.

Remove the head from the pump. If the pump has a

relief valve on head, the valve may have to be removed

before removing the head.

2. Remove the head gasket. If a new gasket is not

available, the original gasket may be re-used provided it

was not damaged when removing the pump head.

3. Remove idler from the idler pin. If the idler pin is worn,

both the idler pin and idler bushing should be replaced.

On the F & FH size the idler & bushing assembly must

be replaced. The idler pin may be removed from the

head by pressing the pin out with a suitable press.

4. Remove the bearing locknut with a spanner wrench

using a suitable wrench on the flat of the shaft to hold the

shaft from turning. A piece of brass rod or wood inserted

in the port area and between the rotor teeth will also hold

the shaft from turning. Remove this piece of brass after

locknut is removed.

5. Remove bracket capscrews and disassemble bracket

from casing.

6. REMAININg DISASSEMBLY PROCEDURE for the

Series 724 packed pump.

(Refer to figure 4).

Remove the packing gland nut, packing gland retainer

washer, and split packing gland halves. The internal

retaining ring, does not need to be removed at this point.

To remove the rotor and shaft, push or tap with a soft

hammer toward the head. The packing and packing

retainer washer can now be removed.

7. REMAININg DISASSEMBLY PROCEDURE for the

Series 4724 mechanical seal pump.

(Refer to fig.

5). Remove the 1/8” socketed head pipe plug on the

casing and loosen the two Allen head setscrews on the

mechanical seal.

fIgURE 4

PACKINg AREA CROSS SECTION

(SERIES 724)

fIgURE 5

MECHANICAL SEAL AREA CROSS SECTION

(SERIES 4724)

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.

PACKINg

PACKINg gLAND

RETAININg WASHER

PACKINg

RETAININg

WASHER

INTERNAL

RETAININg RINg

PACKINg

gLAND NUT

SPLIT PACKINg

gLAND HALVES

PIPE PLUg

PACKINg gLAND NUT

PIPE PLUg

PTfE gASKET

gASKET

SEAL SEAT

ROTARY MEMBER