Thrust bearing adjustment, Installation of carbon graphite bushings, Danger – Viking Pump TSM144: GG-AL 495/4195 User Manual

Page 8

SECTION TSM 144

ISSUE

H

PAGE 8 OF 10

G, GG, H, HJ, HL: Drive the bearing into the bore. Tap

the inner race with a brass bar and

lead hammer to position bearing.

Install the inner snap ring.

AS, AK, AL: Install the bearing retainer washer over

the shaft before installing the ball bearing.

Install the ball bearing in the casing. Drive

the bearing into the bore. Tap the inner

race with a brass bar and lead hammer to

position the bearing.

13. H, HJ, HL: Install the shaft snap ring in groove in

the shaft. See

Figure 9, page 6.

AS, AK, AL: Install the bearing spacer over the shaft

and against the single row ball bearing.

See

Figure 10, page 6.

14. G, GG, H, HJ, HL: Install the ball bearing into the bearing

housing See

Figure 9, page 6. Install

the snap ring into bearing housing to

retain ball bearing. This snap ring has

a tapered edge to fit tapered groove in

bearing housing. The tapered edge is

located away from the ball bearing.

AS, AK, AL: Install the ball bearing into the bearing

housing. Install the lip seal in the bearing

housing end cap. The lip should face

towards the end of the shaft. Put the bearing

spacer collar in the lip seal and install in

the bearing housing and tighten the set

screws securely. See

Figure 10, page 6.

15. Insert a brass bar or piece of hardwood through the port

opening between the rotor teeth to keep the shaft from

turning.

16. Start the thrust bearing assembly into casing. Turn by

hand until tight. This forces the rotor against the head.

Replace and tighten the locknut on shaft.

17. Remove the brass bar or hardwood from port opening.

18. Adjust pump end clearance, refer to “Thrust Bearing

Adjustment”.

Loosen the two screws in the face of the thrust bearing

assembly.

If the shaft cannot be rotated freely, turn the thrust bearing

assembly counterclockwise until the shaft can be turned

easily.

To set end clearance:

1. While turning the rotor shaft, rotate the thrust bearing

assembly clockwise until a noticeable drag occurs. This

is zero end clearance.

2. Mark the position of the bearing housing with respect to

the casing.

3. Rotate the thrust bearing assembly counterclockwise the

distance listed below as measured on outside of bearing

housing.

4. After the adjustment is made, tighten the two setscrews

in the face of the bearing housing assembly to secure

the position.

For viscosities above 2500 SSU, add additional end

clearance (0.004” for G, GG, H, HJ and HL size pumps

and 0.005” for AS, AK and AL size pumps).

When installing the carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a brittle

material and is easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help in installation.

The additional precautions listed below must be followed for

proper installation:

1. A press must be used for installation.

2. Be certain the bushing is started straight.

3. Do not stop pressing the operation until the bushing is in

the proper position, as starting and stopping may result

in a cracked bushing.

4. Check the bushing for cracks after installation.

DANGER !

Before starting pump, be sure all drive

equipment guards are in place.

Failure to properly mount guards may

result in serious injury or death.

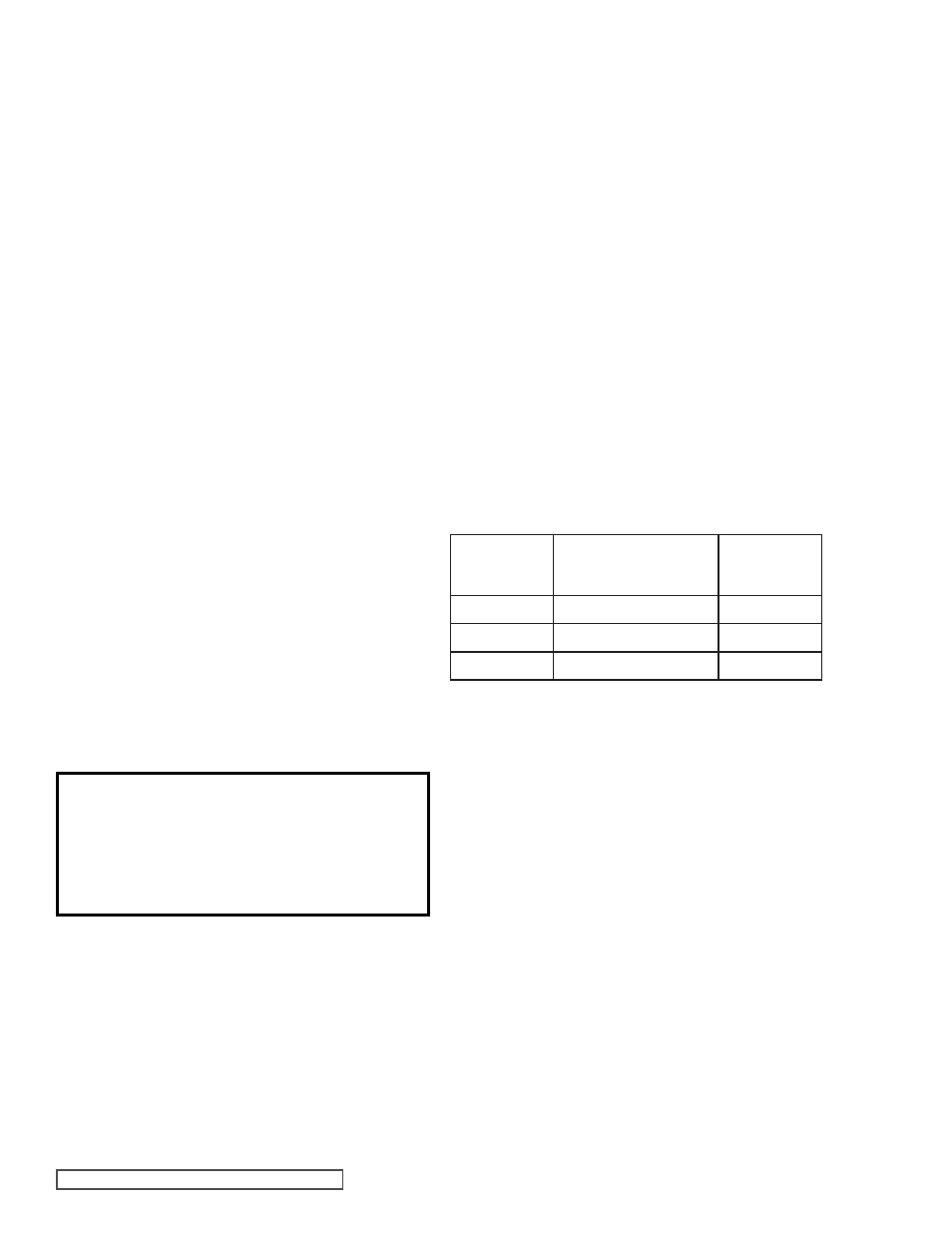

THRUST BEARING ADJUSTMENT

See

Figures 9 and 10.

PUMP

SIZE

DISTANCE IN INCHES

ON O.D. OF BEARING

HOUSING

STANDARD

END

CLEARANCE

G, GG

0.44” (7/16”)

.003

H, HJ , HL

0.56” (9/16”)

.003

AS , AK , AL

0.5” (1/2”)

.003

INSTALLATION OF CARBON

GRAPHITE BUSHINGS