Installation of carbon graphite bushings, Thrust bearing adjustment – Viking Pump TSM142.1: H-LL 225/4225 User Manual

Page 12

SECTION TSM 142.1

ISSUE

F

PAGE 12 OF 13

When installing carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a

brittle material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help in installation.

The additional precautions listed below must be followed for

proper installation:

1. A press must be used for installation.

2. Be certain bushing is started straight.

3. Do not stop pressing operation until bushing is in proper

position. Starting and stopping will result in a cracked

bushing.

4. Check bushing for cracks after installation.

Carbon graphite bushings with extra interference fits are

frequently furnished for high temperature operation. These

bushings must be installed by a shrink fit.

1. Heat bracket or idler to 750 °F.

2. Install cool bushings with a press.

3. If facilities are not available to reach 750 °F. temperature,

it is possible to install with

450 °F. temperature; however,

the lower the temperature, the greater the possibility of

cracking bushing.

Consult factory with specific questions on high temperature

applications.

Refer to Engineering Service Bulletin ESB-3.

INSTALLATION Of CARBON

gRAPHITE BUSHINgS

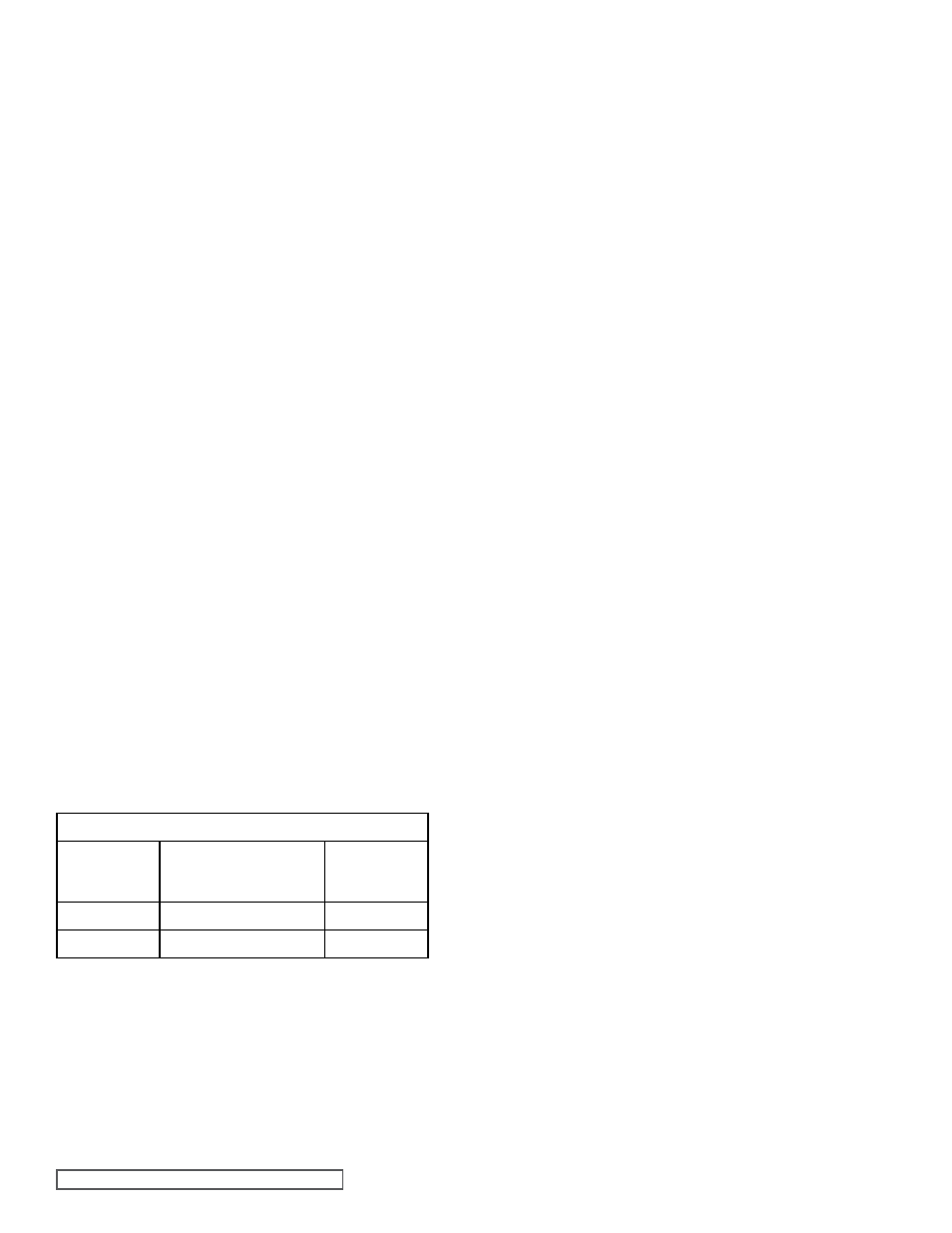

TOTAL END CLEARANCE CHART

PUMP

SIZE

TURN OUTER END CAP

COUNTER-CLOCKWISE

NO. Of NOTCHES

TOTAL

END

CLEARANCE*

H & HL

5

.007

K - LL

8

.010

THRUST BEARINg ADJUSTMENT

1. Loosen setscrews over outer and inner end caps. Two

for H and HL size pumps, four for all other sizes.

2. Turn inner end cap clockwise, viewed from shaft end, until

it projects slightly from bracket exposing approximately

three threads.

3. Turn outer end cap clockwise until rotor is tight against

head and rotor shaft cannot be turned.

4. Make a reference mark on bracket end, opposite a

notch on outer end cap. Back off outer end cap required

number of notches.

Refer to figure 14.

Each 0.25 inch travel on circumference of end cap is

equivalent to approximately .0015 inch for all sizes.

5. End clearances set per Step 4 are adequate for

viscosities up to 750 SSU (SAE20 lube oil at room

temperature). Higher viscosity liquids require additional

end clearances.

As a general guideline, for viscosities between 750 and

7500 SSU (heavier lube oils) double the amount of end

clearance indicated in Step 4; for viscosities between

7500 and 75,000 SSU (e.g., resins) triple the amount

and for viscosities greater than 75,000 SSU (e.g., black

strap molasses) use 4 times the amount.

For specific recommendations for end clearances for

viscosity or for operating temperatures above 225 °F,

check with your Viking representative or consult the

factory.

6. Tighten inner end cap with a spanner wrench. Tap

spanner wrench lightly but

DO NOT OVER TIgHTEN as

it will only damage the threads.

7. Tighten all setscrews that hold inner and outer end caps

to prevent their turning in the bracket.

8. Rotor and shaft should turn smoothly by hand one

complete revolution. If rotor and shaft doesn’t turn

smoothly, go back and repeat

Thrust Bearing

Adjustment Steps 1 thru 8.

* Total End Clearance includes extra clearance for

temperatures of 450°f.

fIgURE 14