Slightly, Increase, Decrease – VICI Two position Standard electric User Manual

Page 17

4.

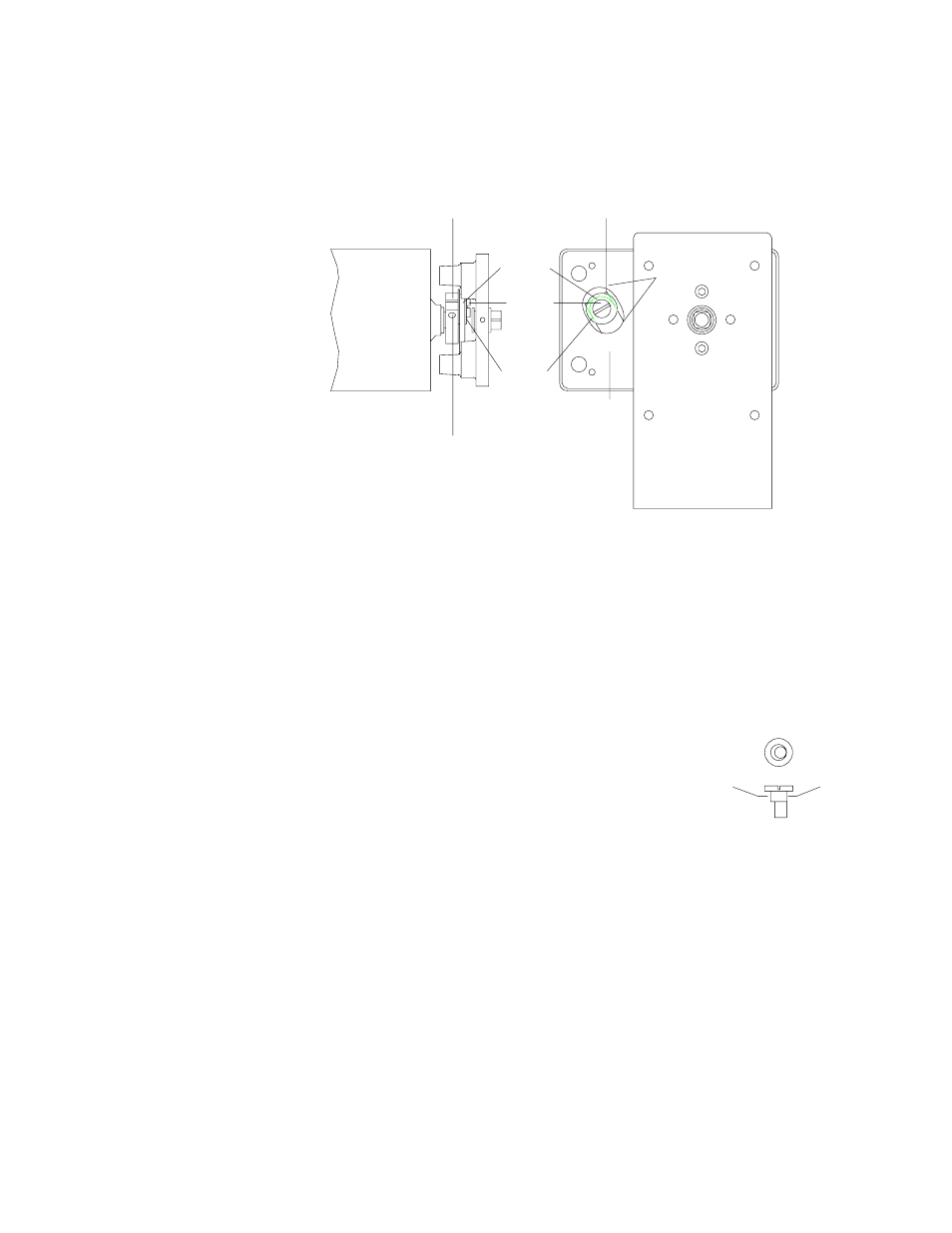

Temporarily install the mounting bracket at 90° from normal (see Figure 12)

so that the adjustment hole is accessible.

5.

Put the clamp ring back on and attach the valve or valve/standoff assembly.

Plug in the actuator power cord and align the valve as nearly as possible, as

described in Section 5.4, Alignment Procedure.

6.

Unplug the power cord.

7.

Use a 7/64 hex driver to loosen the 6-32 cap

screw on the gearshaft crank. (Figure 14)

8.

Use a screwdriver to

slightly

move the gearshaft

crank pin. (Figure 15) To

increase

the stroke,

rotate it slightly (1/16 turn) in the direction which

has the most resistance. To

decrease

the stroke,

rotate it in the direction which has the least resis-

tance.

9.

Lock the 6-32 cap screw on the gearshaft.

10. Plug in the power cord. Cycle the valve several times and check the

alignment. If the valve rotation is still incorrect, loosen the gear shaft crank

screw and readjust the gear shaft crank pin to set rotation correctly.

11. When the rotation is correct, unplug the power cord and reassemble the

electric actuator and valve with all the parts in proper orientation.

12. Realign the valve as described in Section 5.4, Alignment Procedure.

GEARSHAFT

CROSS-

LINK

END OF GEARSHAFT CRANK

GEAR-

SHAFT

CRANK

PIN

NYLON

WASHER

6x32 LOCKING CAP SCREW

FRONT OF

ELECTRIC

ACTUATOR

(Installed 90°

from usual

position)

FRONT OF

BRACKET

BOTTOM OF

ELECTRIC

ACTUATOR

(With bracket

removed)

ADJUSTMENT

HOLE

Figure 14: Actuator stroke adjustment

BOTTOM VIEW

SIDE VIEW

MAXIMUM

EDGE

MINIMUM

EDGE

Figure 15:

Gearshaft crank pin

15