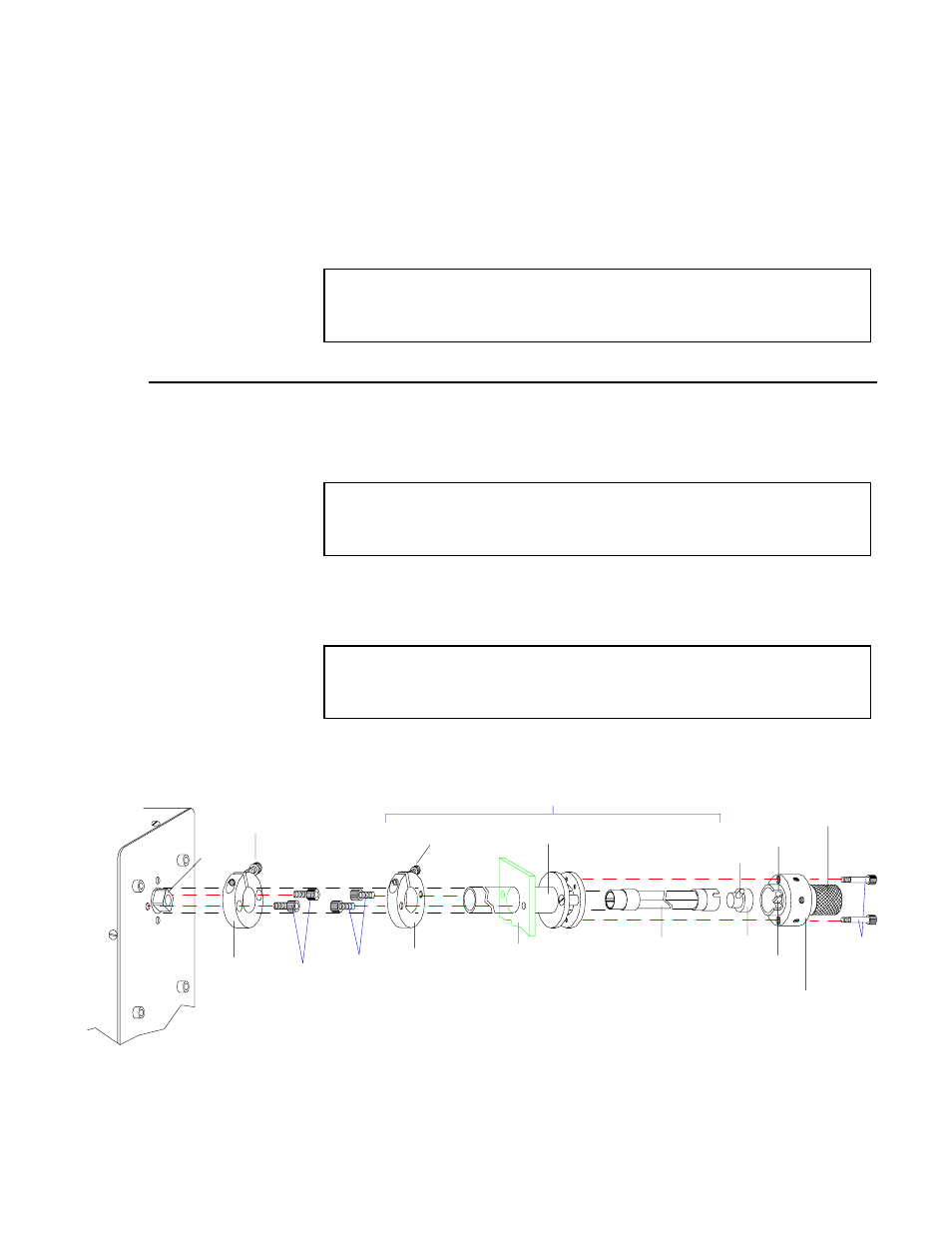

3 installation of a valve with a standoff, Figure 9: valve on actuator with a standoff 9 – VICI Two position Standard electric User Manual

Page 11

coupling on the square driver of the actuator first. However, make sure that

the driver doesn’t get cocked.) The CR41/closemount standoff should end

up flush against the CR4/clamp ring.

5.

Tighten the HWSC-SC6-8B/screw (6-32 x 5/8") in the clamp ring with a

7/64 hex driver.

6.

Align the valve and actuator according to the Alignment Procedure found

in Section 5.4.

CAUTION: If the valve and actuator are not properly aligned, the slots

on the valve rotor and the ports in the valve body will not align properly.

The flow of sample may be blocked, and other problems may result.

4.3 Installation of a Valve With a Standoff

If the electric actuator has been specified for use with a standoff, it will arrive from

the factory with the CR3/clamp ring already on the actuator. The clamp ring is

attached to the actuator with two HWSC-SC8-8B/socket head screws (8-32 x 1/2").

CAUTION: Do not use screws longer than 1/2" to attach clamp rings to

electric actuators. They will interfere with internal moving parts and

damage the actuator.

1.

Plug in the electric actuator and put it into the LOAD position (indicated by a

red light in the LOAD position) on the control box. The valve will have been

rotated to the counterclockwise position before the knob or the handle was

removed, so they should now be in the same relative rotational position.

CAUTION: The valve and the actuator must be in corresponding

rotational positions before assembly. If they are not, the valve or elec-

tric actuator may be damaged when operated.

HWSC-SC6-

10NT/

PRE-LOAD

ASSEMBLY

CUTOUT

ROTOR

PIN

ROTOR

TAB

VALVE

BODY

WD/DRIVER

STANDOFF

DRIVE SHAFT

STANDOFF ASSEMBLY (Lengths vary)

STANDOFF

OPTIONAL

MOUNTING

BRACKET

OR OVEN WALL

HWSC-SC6-8B/

SCREW

CR2/

CLAMP

RING

HWSC-SC8-8B/

SCREWS

SCREWS

(NOT

PRO-

HWSC-SC8-8B/

SCREW

SQUARE

DRIVER

CR3

CLAMP

RING

Figure 9: Valve on actuator with a standoff

9