Tweco XT-301 Torch Data for OEM Use w- Auto-Cut 100 AD User Manual

Page 10

Torch Data

8-10

Manual 0-4734 Rev. AD

Stainless Steel

100A

N2 Plasma / H20 Shield

Plasma

(N2)

Shield

(H2O)

(ga)

(in)

inch

psi

Ball *

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

10

0.141

100

5

160

0.125

160

0.200

0.000

0.074

3/16

0.188

100

5

157

0.125

100

0.250

0.300

0.080

1/4

0.250

100

5

155

0.125

60

0.250

0.300

0.086

3/8

0.375

100

5

159

0.125

50

0.250

0.300

0.087

1/2

0.500

100

5

169

0.130

35

0.300

0.500

0.100

5/8

0.625

100

5

175

0.140

30

0.300

0.600

0.110

3/4

0.750

100

5

177

0.150

25

NR

NR

N/A

Plasma

(N2)

Shield

(H2O)

bar

Ball *

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

6.9

5

161

3.2

4810

4.5

0

1.8

6.9

5

159

3.2

3530

5.5

0.1

1.9

6.9

5

157

3.2

2400

6.4

0.3

2.1

6.9

5

155

3.2

1750

6.4

0.3

2.2

6.9

5

157

3.2

1390

6.4

0.3

2.2

6.9

5

160

3.2

1210

6.5

0.3

2.3

6.9

5

167

3.3

970

7.3

0.5

2.5

6.9

5

173

3.5

800

7.6

0.6

2.7

6.9

5

178

3.9

600

NR

NR

N/A

NOTE: Ohmic height sensing is not recommended with water shield.

Water on the plate interferes electrically with the ohmic sensing circuit.

100A Stainless Steel (N2/H2O)

Material

Thickness

Cut Flow Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Material

Thickness

Cut Flow Pressures

Arc

Voltage

Torch

Working

Height

4

5

Travel

Speed

Initial

Piercing

Height

* Ball setting for shield water is set using a line pressure of 55 psi / 3.8 bar

15

20

6

8

10

12

(mm)

3

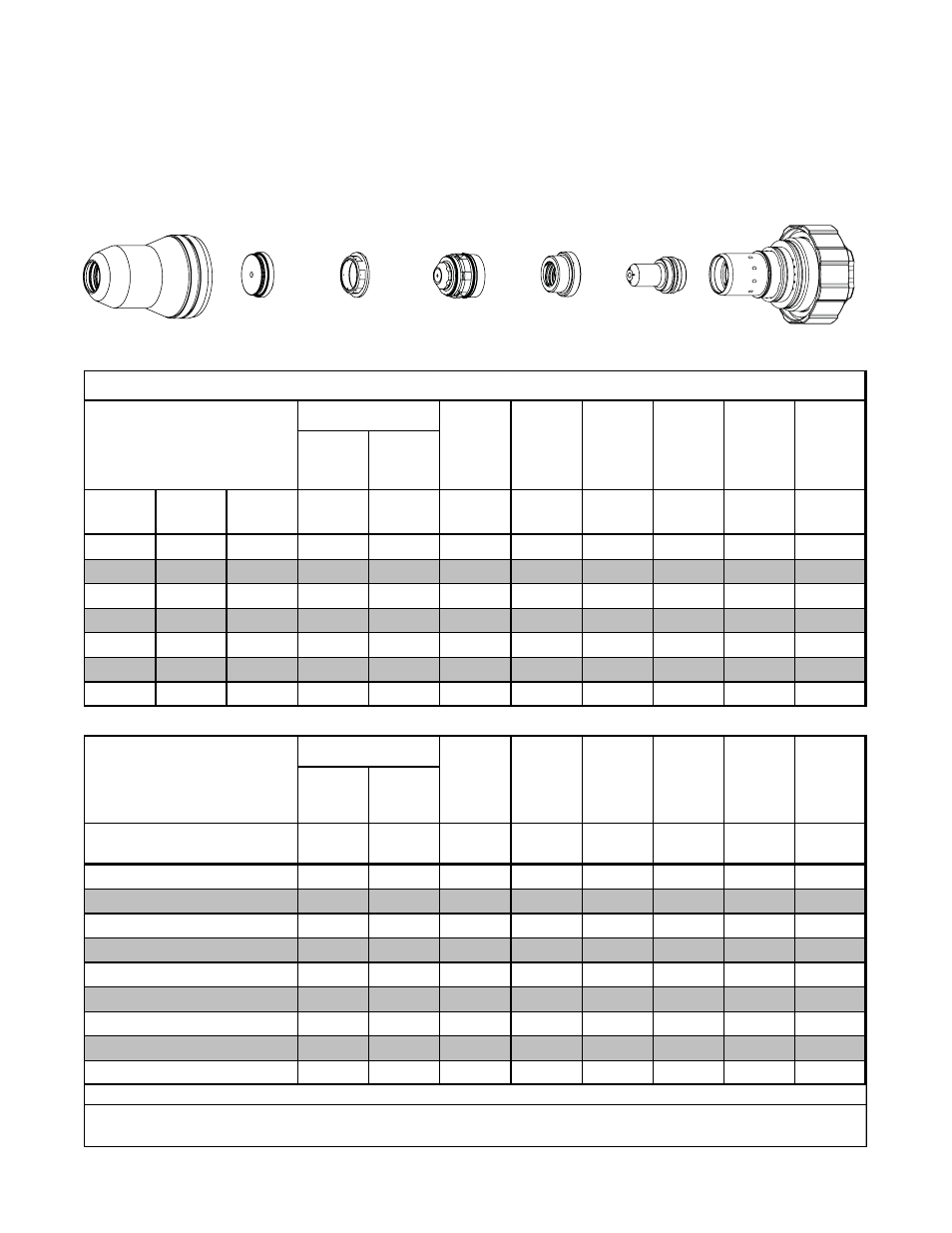

36-1053

36-1041

36-1089

Cartridge

36-1020

Shield Cup

36-1016

Plasma Gas Distributor*

Shield Gas Distributor

Shield Cap

Art # A-07090

36-1272

36-1034

Tip

Electrode