Stainless steel 100a air plasma / air shield – Tweco XT-301 Torch Data for Distributor Use w- Auto-Cut 20 O2 AG User Manual

Page 10

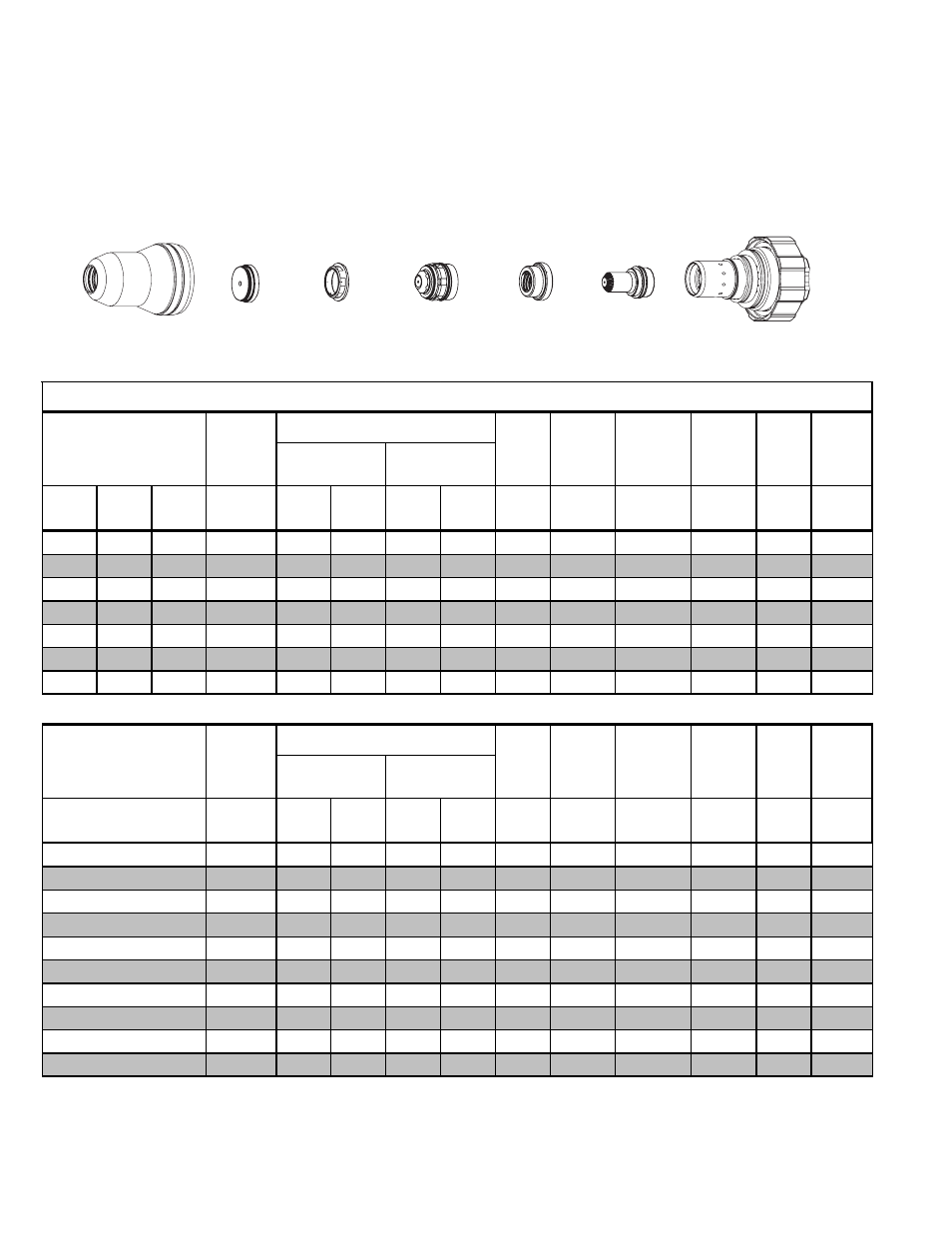

Torch Data

8-10

Manual 0-4821 Rev. AG

Stainless Steel

100A

Air Plasma / Air Shield

(ga)

(in)

inch

psi

Ball

psi

Ball

psi

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

16

0.063

90

58

90

75

90

145

0.080

500

0.200

0.0

0.099

10

0.141

90

58

90

75

90

150

0.100

225

0.325

0.0

0.102

3/16

0.188

90

58

90

75

90

153

0.140

175

0.325

0.1

0.105

1/4

0.250

90

58

90

75

90

157

0.140

100

0.325

0.1

0.105

3/8

0.375

90

58

90

75

90

158

0.140

65

0.325

0.2

0.110

1/2

0.500

90

58

90

75

90

165

0.160

45

0.325

0.4

0.112

5/8

0.625

90

58

90

75

90

168

0.160

35

0.350

1.0

0.114

bar

Ball

bar

Ball

bar

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

6.2

58

6.2

75

6.2

145

2.0

12700

5.1

0.0

2.4

6.2

58

6.2

75

6.2

146

2.1

11290

5.7

0.0

2.5

6.2

58

6.2

75

6.2

149

2.0

6330

8.3

0.0

2.6

6.2

58

6.2

75

6.2

151

3.6

5270

8.3

0.1

2.7

6.2

58

6.2

75

6.2

154

3.6

4170

8.3

0.1

2.7

6.2

58

6.2

75

6.2

156

3.6

3020

8.3

0.1

2.7

6.2

58

6.2

75

6.2

158

3.6

2080

8.3

0.2

2.7

6.2

58

6.2

75

6.2

159

3.6

1580

8.3

0.2

2.8

6.2

58

6.2

75

6.2

163

4.0

1260

8.3

0.4

2.8

6.2

58

6.2

75

6.2

167

4.1

960

8.7

0.8

2.9

Bold type indicates maximum piercing parameters.

Kerf

Width

@ Rec.

Speed

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Plasma (Air)

Shield (Air)

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed

100A Stainless Steel (Air/Air)

Material

Thickness

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

2

3

Travel

Speed

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Plasma (Air)

Shield (Air)

Material

Thickness

Arc

Voltage

Torch

Working

Height

(mm)

12

15

4

5

6

8

10

1.5

Cartridge

35-1020

Shield Cup

35-1016

Shield Cap

35-1027

Shield Gas Distributor

35-1272

Tip

35-1053

Plasma Gas Distributor

35-1041

Electrode

35-1071

Art # A-07295