Tweco 9-9385 User Manual

Page 2

June 23, 2011

2

Manual 0-5059_AB

B. Cover Installation

1. Reverse previous procedures for cover installa-

tion.

NOTE

When installing the upper screws, attempt to reuse

the original threads. The easaiest way to do this

is by turning the screw counter-clockwise until

you feel the threads lign up, then begin to turn the

screw clockwise to tighten. Do not over tighten.

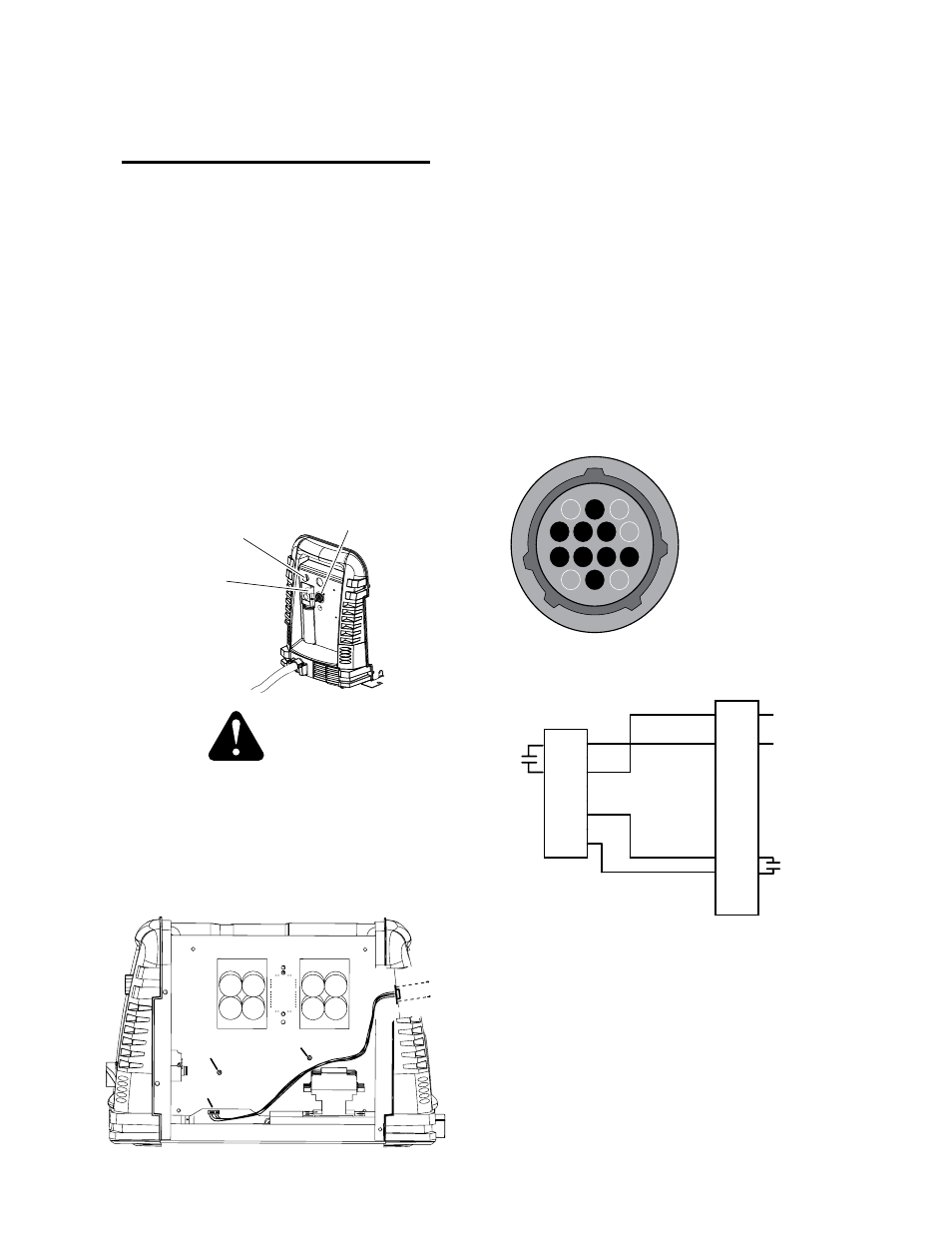

C. Automation Harness Installation

1. Remove the metal plate covering the two access

holes in the rear panel. You can save this for con-

verting back to just a manual system or discard

if you have no intensions of doing so.

2. Using the two screws included in this kit, install

the CPC end of the interface cable harness con-

nector in the lower hole in the back of the power

supply. Tighten the hardware securely. Do not

overtighten.

Automation Interface

Cable Port

Filter Assembly

Input Power Selection

Art # A-08354

CAUTION

Do not overtighten these screws. Overtightening

could strip out the holes in the plastic flange sup-

porting the cable connector.

3. Route the harness behind the contactor and under

existing wiring. Connect the multi pin strip end

of the harness to J-10 on the Main PCB along the

bottom toward the front of the unit.

-V OUT 1

WORK 1

J10

-V OUT 1

WORK 1

Art # A-08357

4. If not using a height sensing device skip to the

next step. If using a customer supplied auto

voltage sensing device for height control, the

wires will need to be fitted with a proper size

ring terminal. Feed those wires through the top

hole in the rear panel. Use an M4 .7x8mm screw

to secure the negative wire to the main PCB at "-V

out 1" above the terminal strip just done. Remove

the screw securing the Work Lead to "Work 1" and

attach the positive wire to this same terminal with

the Work Lead. Secure these wires to the rear

panel with a proper sized Hayco type through

hole protector.

5. If not using a height sensing device just snap the

included plug into the top hole of the rear panel

from the rear.

6. Harness pin-out is as shown in the following il-

lustrations.

Art # A-08356

1

4

12

14

3

3 & 4 - START/STOP

23x5291

12 & 14 -

OK-TO-MOVE,

DRY CONTACT

}

BASIC CNC INTERFACE OPTION

J2

2

3

4

5

6

7

8

9

10

11

12

13

14

1

P10

1

2

3

4

5

6

7

8

Art # A-08387

OK To

Move

5A at

250VAC

or 30VDC

OK TO MOVE

/START / STOP

+

-

If using a

switch, it

must withstand

12VDC at 50mA

This completes the installation of the Automation Kit.

NOTE

Every effort has been made to provide com-

plete and accurate information in this manual.

However, the publisher does not assume and

hereby disclaims any liability to any party

for any loss or damage caused by errors or

omissions in this Manual, whether such er-

rors result from negligence, accident, or any

other cause.