Triton WCA 201 User Manual

Page 4

6

7

GB

GB

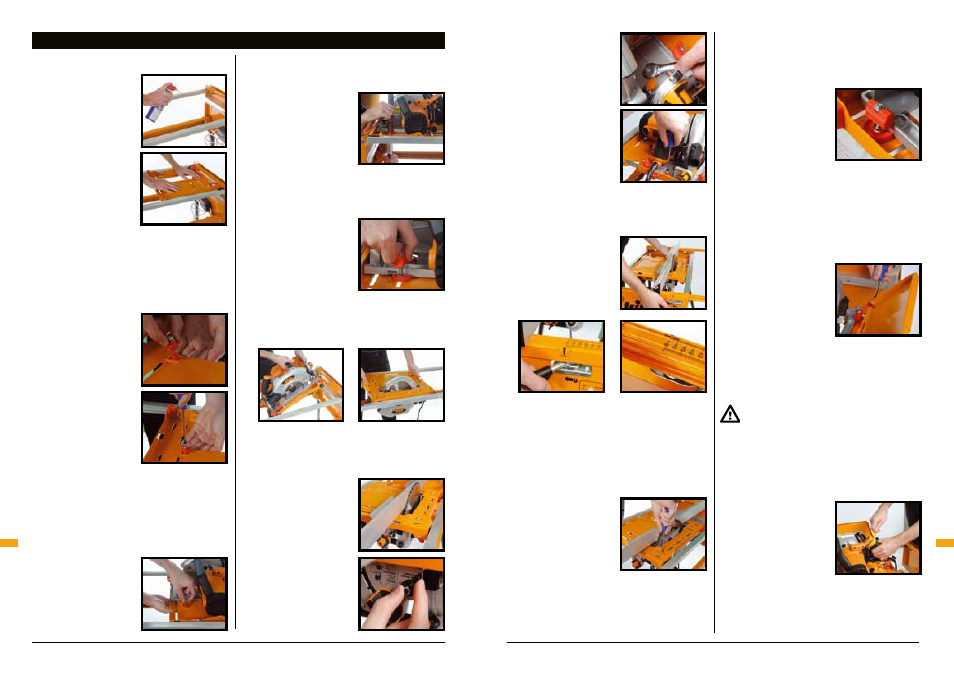

Fitting the slide chassis

Place the Slide Chassis

(L) in the bearing

channels with the red

plastic catch and red

bearing spacers closest

to the front panel (the

switch box end) and the

flanges upwards. Enter

two bearings in the

channel cutouts. Slide

the chassis towards

the rear panel and the

other bearings will

drop in.

Spray the channels

with lubricating oil for a smooth slide.

Fitting the triton saw

Unplug your saw. Check that the blade is set

at 0° and at full depth of cut.

Fit the Saw Alignment

Cams (o) from below,

holding the bases in

the rectangular slots

while you screw into

them. (They cut their

own thread.) Make sure

the lines moulded on

top of the cams are

both pointing towards

the rear panel. Tighten

the screws until nipped

gently.

Fitting the saw locators and knobs

Fit the saw into the chassis with the alignment

cams locating in the holes in the saw base-

plate.

Break or cut the Saw Locators (k) and

Clamping Knobs (l) from their moulding "tree"

and carefully trim off

any remnants with a

sharp knife. Fit the saw

locators in the slots

shown using 4 M6 x

40 screws (m) and M6

Flange nuts (n). The straight edges should be

against the baseplate, but spaced away from it

slightly to allow for final saw adjustment.

(Use a spatula blade or

a piece of cardboard or

metal about 1mm thick

as a spacer.) Firmly

tighten the screws.

Screw the knobs on

(they cut their own thread) until they just

scrape against the top edge of the saw base-

plate. This tension is sufficient to hold the

saw upside-down for

final adjustment, and

still allow the saw to be

shifted sideways slightly

using the alignment

cams.

Check that the saw is securely mounted.

Turn the slide chassis over, re-engaging the

bearings in the channels.

Aligning the saw

Position the chassis halfway between the end

panels. Adjust the fence in close to the blade

and lock it. Make sure

the blade is vertical

by comparing it to the

face of the fence. If

necessary, loosen the

nut holding the Blade

Angle Trimmer, and

adjust the blade angle.

Re-tighten the nut.

Use the saw's spanner

or the Tube Spanner (s)

to rotate the cams until

the front and rear of the

blade are just touching

the fence, when it is at

0mm. When satisfied

with the position tighten

the alignment cam

screws.

Unscrew the front

handle of the saw for

better access to the

front cam. Lower the

blade for access to the

rear one.

Final clamping of saw

Double-check the saw position by now locking

the fence at 0mm, and trying to turn the

blade backwards by

hand. The teeth should

lightly scrape against

the face of the fence. If

not, repeat the above

alignment.

This is a very important step, because it will

ensure that your saw cuts are true, and that

your fence scales are accurate, so take your

time.

When satisfied with the position of the

saw,reposition the saw locators hard up

against the edge of the baseplate, as follows.

Hold each knob against

turning and loosen the

screw about half to

one turn. Push the saw

locator into position,

and firmly tighten the

screw.

Turn the saw right-way

up again and loosen the four knobs a couple

of turns. Check that the saw cannot move

sideways at all, and that all screws are fully

tightened. Do up the knobs again, perhaps

one turn beyond when they first scrape on the

baseplate.

The saw is now set up, and is available at any

time for hand-held use by simply loosening

each knob half a turn

and lifting the saw

straight up. If the

locators are correctly

fitted, the saw will go

back into exactly the

right spot each time.

Fitting the side guard

Slide the two sections of the Side Guard (K)

together until they fit between the pivot

brackets on the slide chassis. Loosely fit the

short M5 x 8 screw (i) and a M5 Nyloc nut (h)

to hold them together.

Fit the two longer M5

x 25 screws (j) and

M5 Nyloc nuts through

the pivot brackets and

into the guard flanges.

Tighten until the guard

is firm, but still free to

pivot. Finally, tighten

the screw holding the two halves together.

Fitting the trigger strap

Before fitting the Trigger Strap (q) always

ensure that the saw is disconnected

from the power and that the switch on

the Workcentre front panel is in the "OFF"

position.

Wrap the Trigger Strap (q) around the handgrip

with the furry side facing outwards. Pass the

strap through the buckle, until the security

loop has passed

through. If your saw

has a safety lock-out

button press it and then

tighten the strap until

the trigger clicks "ON".

FITTING THE TRITON 235MM POWER SAW

Fitting The Triton Saw

Fitting The Triton Saw