2 component identification, 3 screw-in tools for seats, 4 tightening torques – Richter LPV/F Series Low-Pressure Safety Valves User Manual

Page 4: 5 pressure-temperature-diagram, Component identification, Screw-in tools for seats, Tightening torques, Pressure-temperature-diagram, Series lpv-a/f, lpv-d/f

Series LPV-A/F, LPV-D/F

Seite 4

9530-060-en

Revision 01

TM 7464

Edition 02/2009

1.2 Component identification

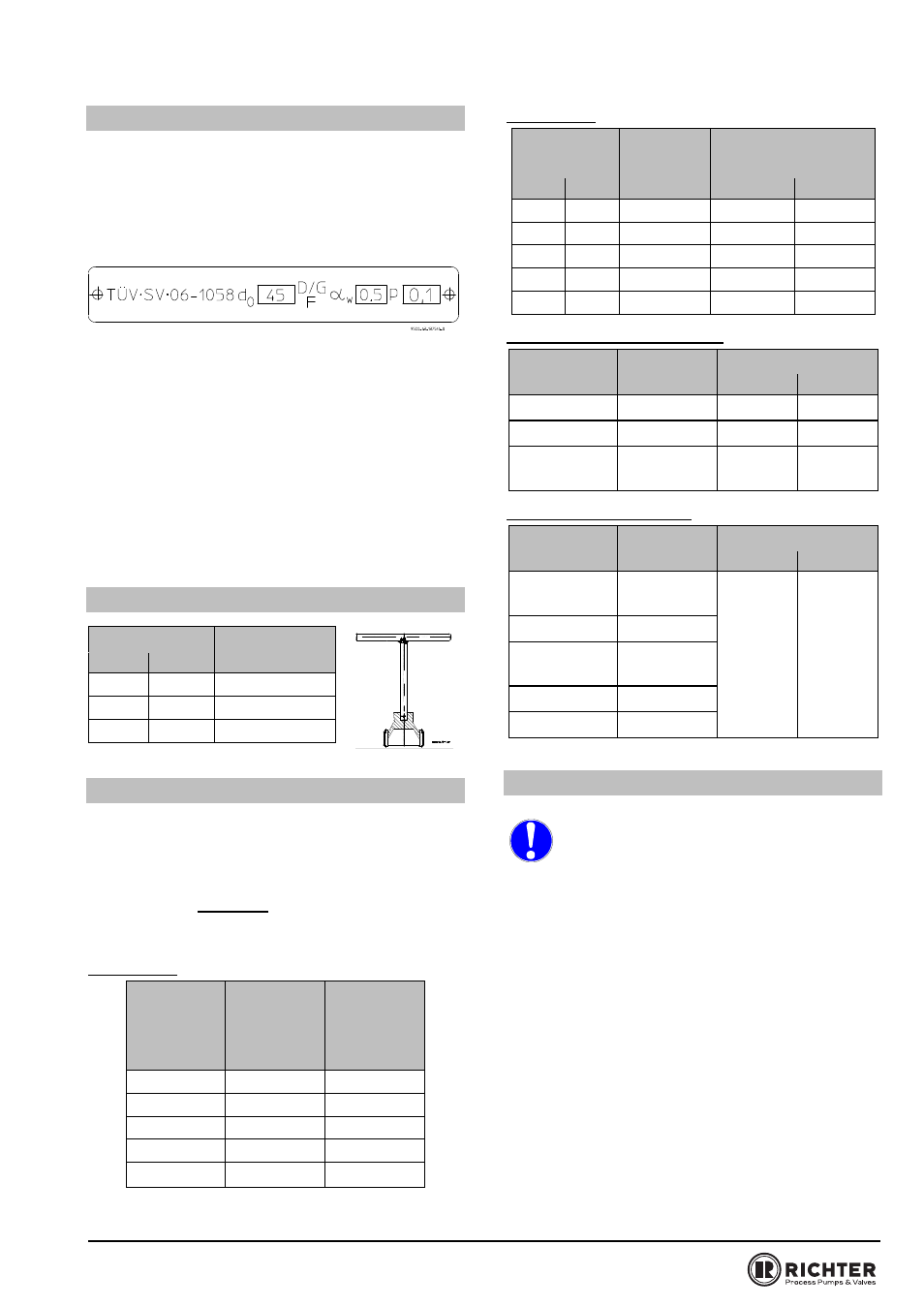

Certified low-pressure safety valves LPV-A/F and

LPV-D/F are identified with a certification plate to the

German data sheet A2. This stainless steel plate is

riveted to the valve body.

It contains the following details for example:

TÜV = TÜV symbol

SV

= Safety valve

06

= Year of certification (here: 2006)

1058 = Certification number (here: 1058)

d0

= Narrowest flow Ø in mm (here: 45)

D/G = intended for discharging vapours/gases

F

= intended for discharging liquids

= Certified coefficient of discharge

(here: 0,5 for D/G and F)

p

= Einstellüberdruck in bar (hier: 0,1)

1.3 Screw-in tools for seats

Nominal size

Article No.

[mm]

[inch]

50

2“

9568-96-1016

80

3“

9568-96-1017

100

4“

9568-96-1018

1.4 Tightening torques

All screws greased, tighten in diametrically

opposite sequence!

The tightening torques for pipe screws and body

screws mentioned must not be exceeded. For an

exception, see Section 8, Flange connection valve /

pipe is leaking.

The following tightening torques are recommended.

Pipe screws, flanges to DIN/ISO

Flange

Nominal

size

Screws

Tightening

torque

[mm]

[ISO/DIN]

[Nm]

25

4 x M 12

10

50

4 x M 16

26

80

8 x M 16

25

100

8 x M 16

35

150

8 x M 20

65

Pipe screws, DIN/ISO flanges drilled to ASME

Flange

Nominal size

Screws

Tightening torque

[mm] [inch]

[ASME]

[Nm]

[in-lbs]

25

1"

4 x ½“

8

70

50

2"

4 x R“

25

220

80

3"

8 x R“

45

400

100

4"

8 x R“

35

310

150

6"

8 x ¾“

80

710

Screws for body / inlet nozzle

Valve type

Screws

Tightening torque

[Nm]

[in-lbs]

LPV-A 50/80

4 x M 12

25

220

LPV-A /100

8 x M 10

20

177

LPV-A

100/150

8 x M 16

25

220

Screws for body / bonnet

Valve type

Screws

Tightening torque

[Nm]

[in-lbs]

LPV-A 50/80,

LPV-D 50

4 x M 12

25

220

LPV-A 80/100

4 x M 12

LPV-A

100/150

8 x M 12

LPV-D 80

8 x M 12

LPV-D 100

8 x M 12

1.5 Pressure-temperature-diagram

When used in the minus temperature range,

the regulations applicable in the country in

question must be observed.

The diagram shows the max. admissible pressure/

temperature load of the body.