7 operation, 1 initial commissioning, 2 shutdown – Richter LPV/F Series Low-Pressure Safety Valves User Manual

Page 11: 3 recommissioning, 4 improper operation and their consequences, Initial commissioning, Shutdown, Recommissioning, 7operation, Series lpv-a/f, lpv-d/f

Series LPV-A/F, LPV-D/F

Seite 11

9530-060-en

Revision 01

TM 7464

Edition 02/2009

7

Operation

7.1 Initial commissioning

Normally, the valves have been tested for leaks with

air or water.

Unless otherwise agreed there could be

residual amounts of water in the flow section

of the valve; this could result in a possible

reaction with the medium.

The max. operating pressure of the plant must

always be below the safety valve reseating

pressure.

To prevent leaks, all connection screws should be

retightened after the initial loading of the valve with

operating pressure and operating temperature.

For tightening torques, see Section 1.4.

7.2 Shutdown

The local regulations are to be observed when

dismantling the valve.

Prior to undoing the flange connection

ensure, that the plant is depressurised and

emptied.

Prior to the start of maintenance work, the valve

must be thoroughly cleaned. Medium residue may

be in the valve even if it has been properly drained

and flushed.

After dismantling, immediately protect the valve

flanges against mechanical damage by using

flange caps. See also Section 6.4.

7.3 Recommissioning

When the valve is recommissioned, it must be

ensured that all appropriate steps, as described in

Sections 6 and 7.1, are repeated.

7.4 Improper operation and their

consequences

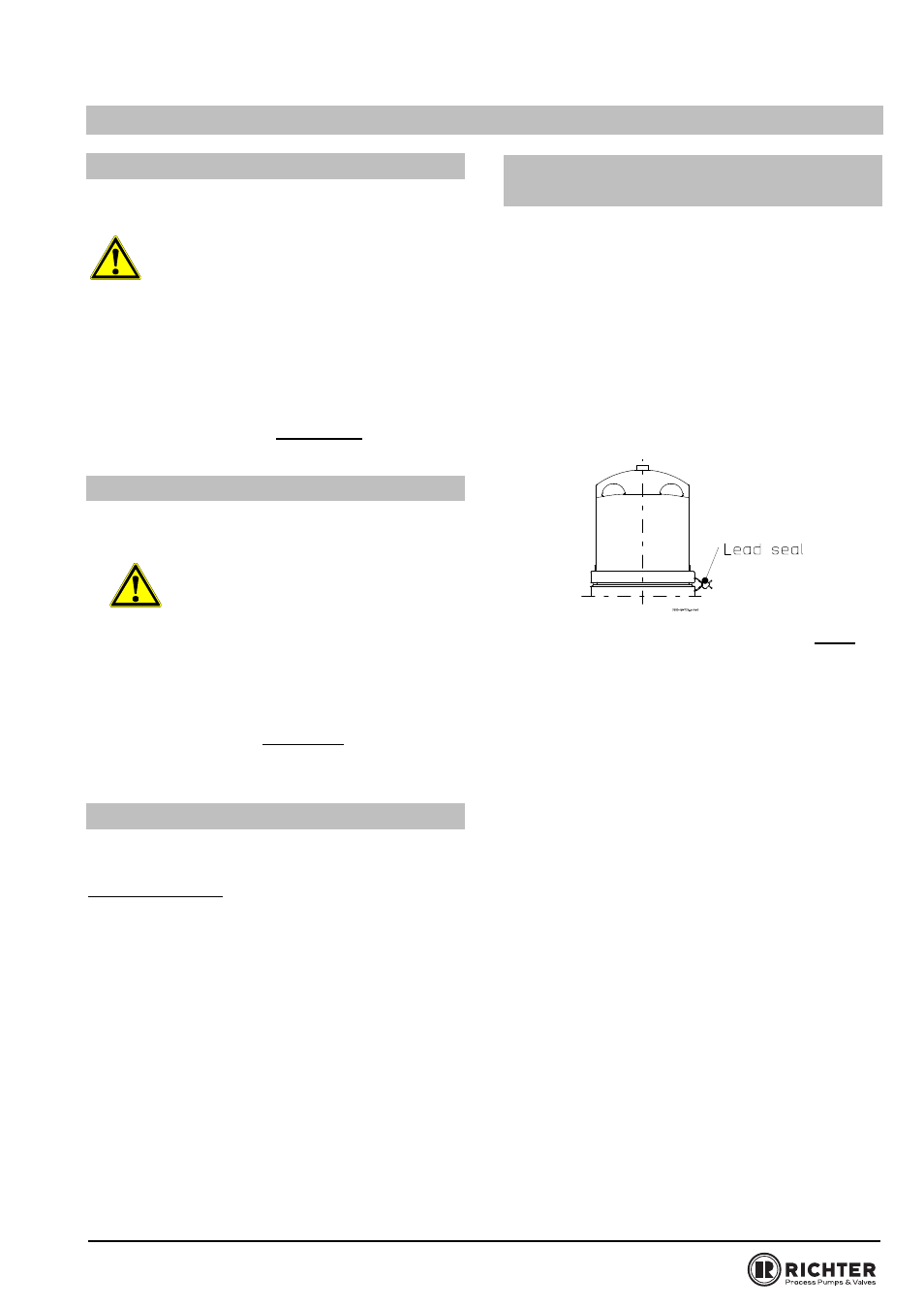

The test pressure, checked by the manufacturer,

an approved authority or the supervisory company

responsible is secured against unauthorised

adjustment by a lead seal.

A broken lead seal must be replaced without delay.

This can either be done by the manufacturer, the

approved authority or the supervisory company

responsible.

It is emphasised that in the case of the

operating company adding the lead seal itself,

it automatically assumes full responsibility for

any operational hazard and resulting damage.

Fig. 2

The travel set at the manufacturer's works ensures

reliable operation of the valve. It is forbidden to

arbitrarily alter the travel or to totally block the

valve.

During operation of the valve, no hard foreign

matter may be found between the seat and the

plug of the valve.

If foreign matter is deposited on the sealing

surfaces during reseating of the valve, the valve is

probably not tight. Damage may also occur to the

plastic sealing surfaces.