4 changing the test gauge pressure, 5 replacement of components, 1 subassembly shut-off element – Richter LPV/F Series Low-Pressure Safety Valves User Manual

Page 13: 2 dismantling of the plug, 3 dismantling of the seat, 4 installation of the seat, 5 installation of the plug, Changing the test gauge pressure, Replacement of components, Subassembly shut-off element

Series LPV-A/F, LPV-D/F

Seite 13

9530-060-en

Revision 01

TM 7464

Edition 02/2009

9.4 Changing the test gauge

pressure

Unscrew bonnet 112.

Remove subassembly shut-off element.

Remove retainer ring 544 and round cord 522.

Push number of weights 239, depending on the

test pressure, onto the plug 204.

See Section 6.5.

Secure with round cord 522 and retainer ring 544.

Install subassembly shut-off element in the body

100.

Screw on bonnet 112 and tighten.

Check test pressure.

Have valve lead-sealed.

The data specified in the data sheet are to be

observed.

9.5 Replacement of components

Always replace the seat 205 and plug 204

completely.

Reworking of the seat and plug requires

specialised knowledge of the materials, their

processing and special lapping wheels. It is

therefore recommended to have this work carried

out by the manufacturer.

After dismantling, check all parts for wear and

damage.

Spare parts are to be ordered with all the details in

acc. with the valve identification.

Only use original spare parts.

9.5.1 Subassembly shut-off element

9.5.2 Dismantling of the plug

Undo screws 901/1 (on the LPV 100/150 902/2)

and 920/2 from body 100 and bonnet 112 and

remove.

Remove bonnet 112..

Remove subassembly shut-off element (without

seat).

Remove retainer ring 544 and round cord 522.

Remove weights 239.

Unscrew lifting aid 237.

9.5.3 Dismantling of the seat

Dismantle bonnet 112 and subassembly shut-off

element from the body 100. See Section 9.5.2.

Only LPV-A/F: Undo screws 902/1 and 920/1 from

inlet nozzle 122 / body 100 and remove.

Remove seat 205.

Only LPV-D/F: For the dismantling and installation

of the seat it is necessary to use the screw-in tool

(it is not part of the valve supply). See Section 1.3.

9.5.4 Installation of the seat

Centre the new or reworked seat 205 in the body

100.

Only LPV-A/F: Then insert the inlet nozzle 122 into

the centring of the body 100.

The components must be smooth running, i.e. can

be centred without any constraining forces.

If necessary, the inlet nozzle is to be turned

through 90°.

First tighten the attachment nuts 920/1 hand-tight

and then with a torque wrench evenly and in

diametrically opposite sequence.

It is imperative to observe the prescribed

torques for the connection body / inlet

nozzle! See Section 1.4.

Only LPV-D/F: Screw-in the seat 1 using the

screw-in tool. See Section 1.3.

9.5.5 Installation of the plug

All parts are to be thoroughly cleaned before

assembly.

Screw lifting aid 237 onto the new or reworked

plug 204.

Push number of weights 239, depending on the

test pressure, onto the plug 204.

Secure with round cord 522 and retainer ring 544.

Install subassembly shut-off element in the body

100.

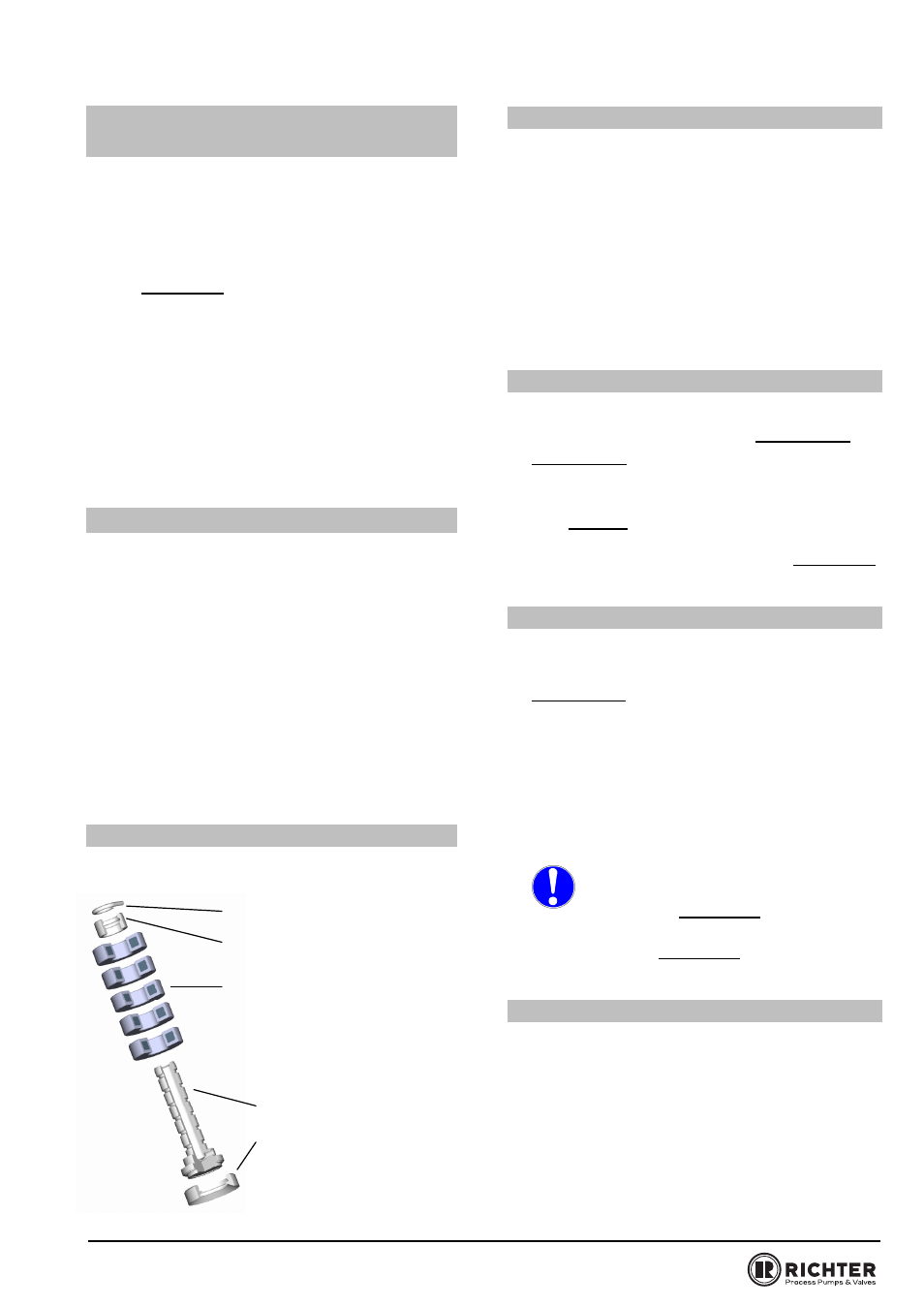

522

544

239

204

The subassembly

shut-off element

contains of:

522

round cord

544

support ring

239

weights

204

plug

237

lifting aid

237