3 transport and storage, 1 return consignments, 2 disposal – Richter MNK Series User Manual

Page 9: Return consignments, Disposal, 3transport and storage

Series MNK 200-150-315

Page

9

9230-053-en

Revision 12

TM 8195

Edition 03/2011

3

Transport and storage

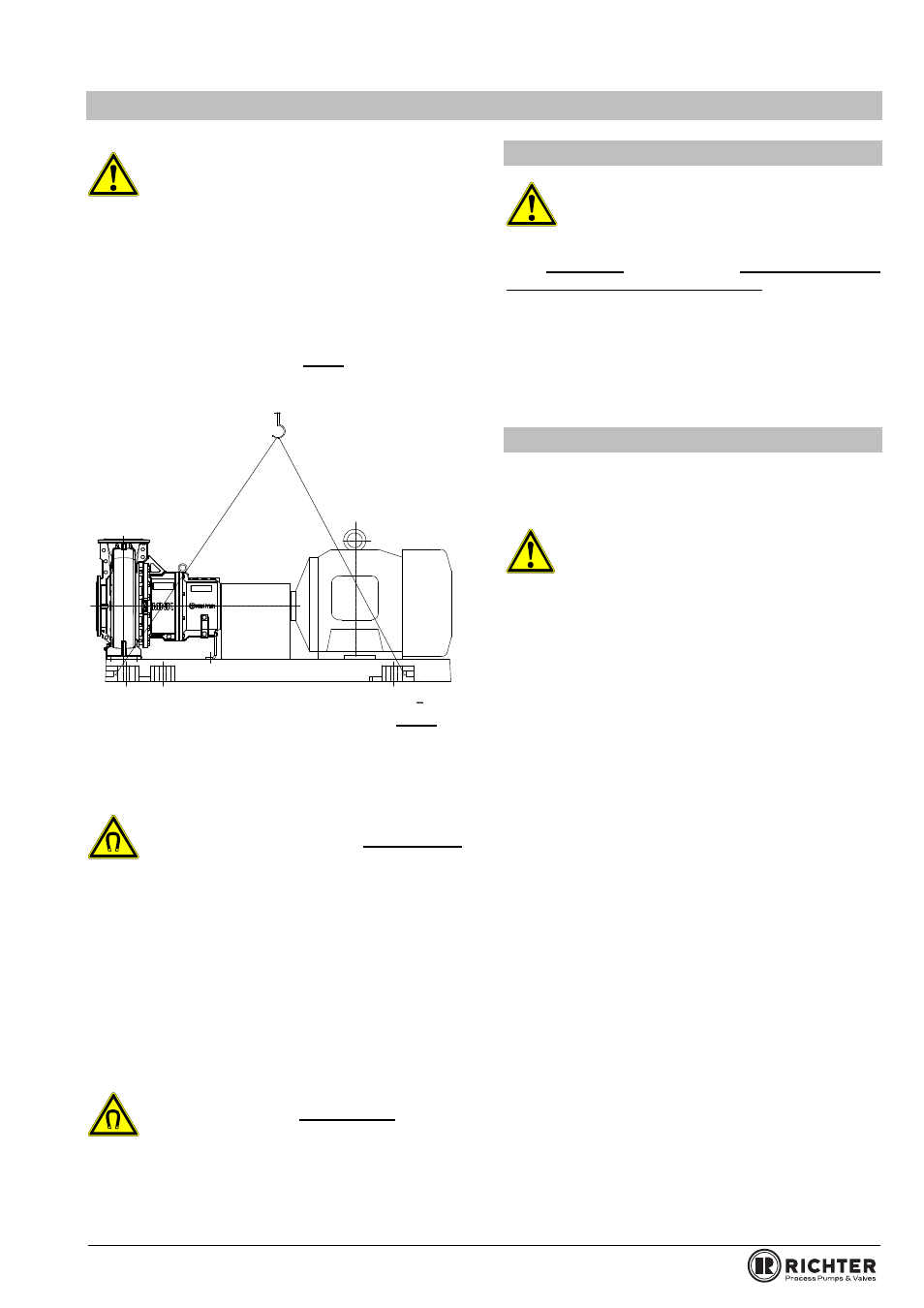

The pump or the unit must be transported

properly. Ensure that during transport the

pump/unit remains in the horizontal position

and does not slip out of the transport

suspension points.

A pump or the motor can be suspended from the

crane hook lug provided for this purpose.

The suspension points are not suitable for

transporting a complete unit, i.e. pump with base plate

and motor.

In this case, the slinging points for the ropes on the

base plate are to be used. See Fig. 1.

Do not attach the slinging ropes to free shaft ends or

to the ring bolt of the motor.

Fig. 1

Directly after receipt of the goods, check the

consignment for completeness and any in-transit

damage.

Do not install damaged pumps in the plant.

When unpacking magnetic drives as single

parts, the relevant notes in Section 7.5.2

must be observed.

Flange covers serve as protection during transport

and must not be removed.

If the unit is not installed immediately after delivery, it

must be put into proper storage.

The product should be stored in a dry and vibration-

free, well ventilated room at as constant a

temperature as possible.

Elastomers are to be protected against UV light.

In general, a storage period of 10 years not exceed.

An admissible storage period of 4 years applies to

elastomers made of NBR.

If magnetic drives are stored as single parts,

the relevant notes in Section 7.5.2 are to be

observed.

In the case of prolonged storage conservation agents

on machined component surfaces and packing with a

desiccant may be necessary.

3.1 Return consignments

Pumps which have conveyed aggressive or

toxic media must be well flushed and cleaned

before being returned to the manufacturer's

works.

It is imperative to enclose a safety information

sheet / general safety certificate on the field of

application with the return consignment.

Pre-printed forms are enclosed with the installation

and operating manual.

Safety precautions and decontamination methods are

to be mentioned.

3.2 Disposal

Parts of the pump may be contaminated with medium

which is detrimental to health and the environment

and therefore cleaning is not sufficient.

Risk of personal injury and damage to the

environment due to the medium or oil!

Wear protective clothing when work is performed

on the pump.

Prior to the disposal of the pump:

Collect any medium, oil etc. which has escaped

and dispose of it in accordance with the local

regulations.

Neutralise any medium residues in the pump.

Separate pump materials (plastics, metals etc.)

and dispose of them in accordance with the local

regulations.