11 assembly aids, 1 boring template for housing drain, 2 pull-off device for plain bearing bushes – Richter MNK Series User Manual

Page 29: Assembly aids, Boring template for housing drain, Pull-off device for plain bearing bushes, Inner magnet assembly clamping device

Series MNK 200-150-315

Page

29

9230-053-en

Revision 12

TM 8195

Edition 03/2011

11 Assembly aids

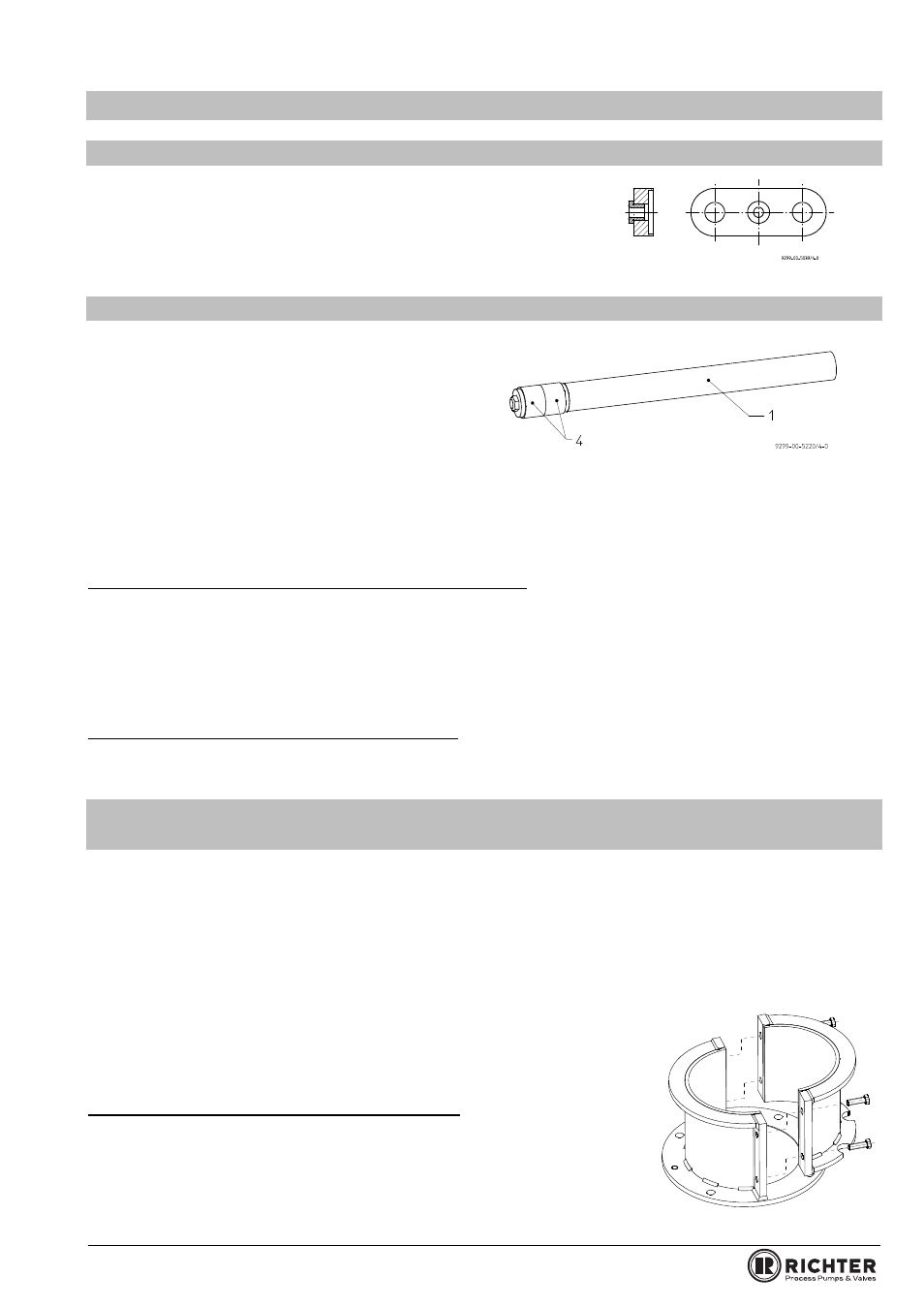

11.1 Boring template for housing drain

Pump size

Ident. No.

MNK 200-150-315

9217-89-1097

11.2 Pull-off device for plain bearing bushes

Pump size

Ident. No.

MNK 200-150-315

9237-89-1138

Product description

If the plain bearing bushes have to be removed from the plain bearing pedestal, we recommend the use of a

special pull-off device. It prevents unnecessary damage to the shock-sensitive silicon carbide components through

the use of suitable materials.

This device is made of malleable rubber material with a plastic handle (polyethylene).

Application

Remove plain bearing bush on the inner magnet assembly side:

Push the device with the rubber part at the front through the plain bearing pedestal from the impeller side.

Position the two rubber parts centrally on the bearing bush.

Axially tighten the rubber parts by turning the handle to the right; as a result they expand radially.

This creates a friction connection between the device and the plain bearing bush which does not damage the

material.

The bearing bush can now be removed by hitting the handle centre axially.

Removing the plain bearing bush on the impeller side:

Use the device following the same procedure from the inner magnet assembly side.

11.3 Universal impeller wrench and universal inner magnet assembly

clamping device

Pump size

Ident. No.

MNK 200-150-315 Clamping device

9237-89-1131

MNK 200-150-315 Impeller wrench

9237-89-1130

7 blades

Hydraulic 1

9237-89-1132

6 blades

Hydraulic 2

Product description

The loosening torque can be up to 800 Nm depending on the magentic drive

torque installed. To ensure that the rotating unit can be easily dismantled, we

recomend the use of the universal impeller wrench in conjunction with the

universal inner magnet assembly clamping device.

Universal inner magnet assembly clamping device

It is advisable to secure the clamping device on a work bench with screws M16

using the 4 bores. Two tapped bores M 12 are provided for transport.

The device consists of two non-magnetisable tube halves one of which is

welded to the base plate. The other half can be removed by undoing the 4 hex.

head screws.