3 suction line, 4 supply lines, 5 discharge line – Richter RMA-B Series (ASME) User Manual

Page 12: 6 venting and evacuating, 5 pipe fittings, 6 monitoring facilities, Suction line, Supply lines, Discharge line, Venting and evacuating

Series RMA-B

close-coupled design

Page 12

9475-055-en

Revision 14

TM 8256

Edition 06/2011

5.4.3 Suction line

The suction lines must always be laid on a rising

gradient towards the pump. Otherwise, gas bubbles

may form which considerably reduce the suction line

cross section. Eccentric transition elements must be

installed between different pipe diameters.

Valves which disrupt the course of flow should not be

installed directly upstream of the pump.

Fig. 3

5.4.4 Supply lines

Supply lines should vent towards the reservoir and

are therefore to be laid with a constant downward

gradient towards the pump. Should the piping

internals upstream of the pump be horizontal, a low

point can, of course, be located upstream of these

internals. From here the pipe is then laid with an

upward gradient to the pump so that the gas bubbles

which form here can escape through the pump.

Valves which disrupt the course of flow should not be

installed directly upstream of the pump.

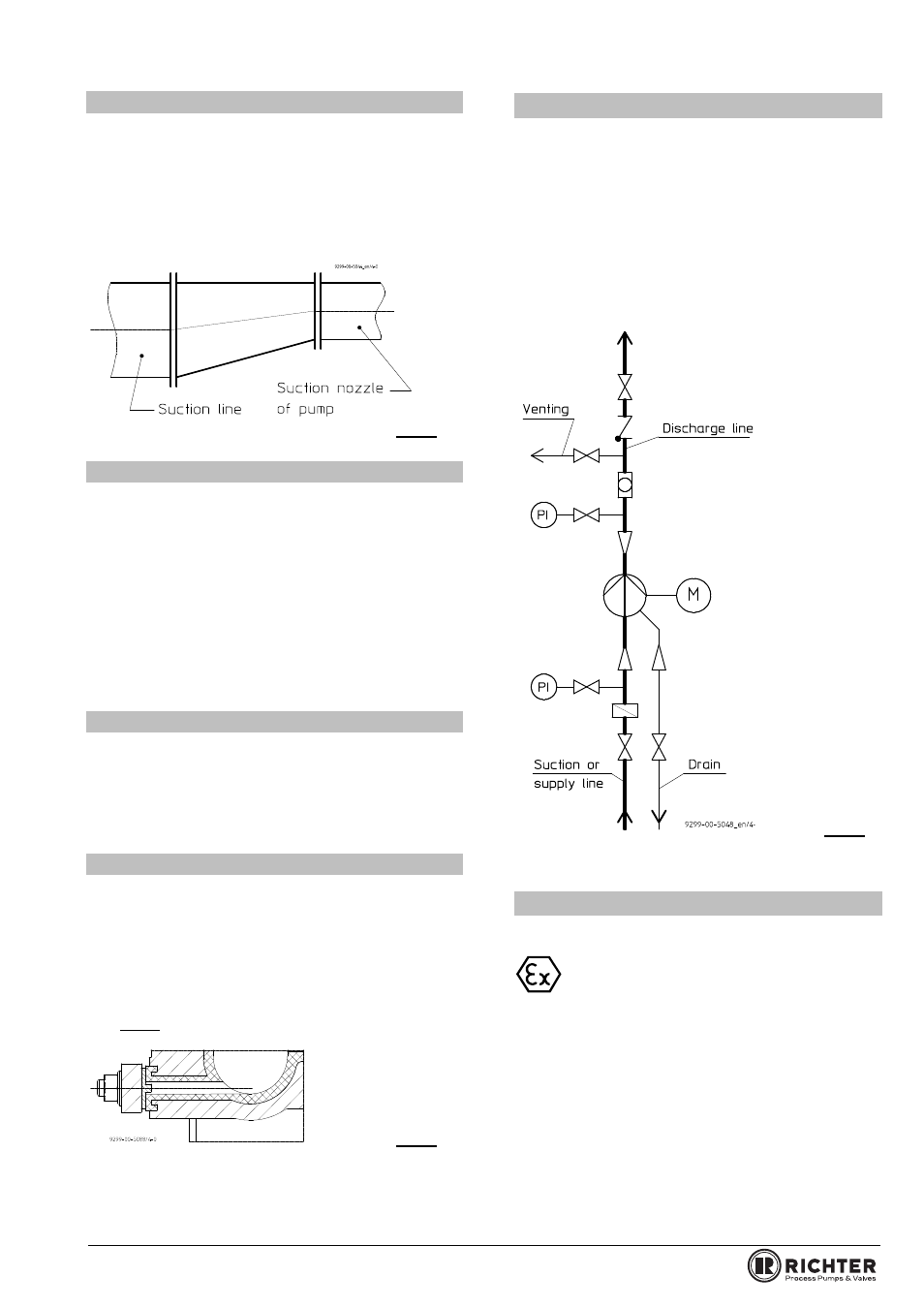

5.4.5 Discharge line

Do not arrange the shut-off valve directly above the

pump but initially provide a transition section.

The discharge nozzle velocity of the medium can – if

necessary – be reduced.

5.4.6 Venting and evacuating

Venting can take place into the discharge line or

upstream of the discharge valve.

A venting line can also be used as a bypass, drain or

flushing line.

The pump housing is fitted with a drain connection as

a standard feature. Optionally, the drain bore can be

drilled.

See Fig. 4.

Fig. 4

5.5 Pipe fittings

The following pipe fittings are available from Richter

on request:

Shut-off valves

Check valves

Sight glasses

Priming vessels

Strainers

Pressure gauges

Fig. 5

5.6 Monitoring facilities

Appropriate monitoring facilities are to be

recommended,

depending

on

the

requirements placed on operational safety

and availability of the unit.

Richter provides information on request and can

supply:

Flow meters

Filling level indicators

Motor load monitors

You can obtain the publications "Safe Operation of

Magnetic Drive Pumps" and "The Operation of

Centrifugal Pumps without NPSH Problems" on

request.