5 installation, 1 safety regulations, 2 installation of pump/unit – Richter RMA-B Series (ASME) User Manual

Page 11: 3 alignment of pump - motor, 4 piping, 1 nominal size, 2 nozzle loads, Safety regulations, Installation of pump/unit, Alignment of pump - motor

Series RMA-B

close-coupled design

Page 11

9475-055-en

Revision 14

TM 8256

Edition 06/2011

5

Installation

5.1 Safety regulations

Equipment which is operated in potentially

explosive areas must satisfy the explosion

protection regulations.

People with a pacemaker are at risk from the

strong magnetic field of the magnetic drive. It

may be life-threatening for them to stay at a

distance of less than 20” (500 mm) to the

pump.

5.2 Installation of pump/unit

The structural work must be prepared in accordance

with the dimensions in the installation drawing.

Method of installation: on a grouted base plate and

firm foundation

Align base plate on the ground foundation.

Insert foundation bolts and grout base plate.

Do not tighten the foundation bolts uniformly and

firmly until the mortar has set.

Other possibilities of installing the pump are:

4-point installation

4-point installation with base plate.

As soon as additional installations are

mounted, the stability of the entire unit

installed without a foundation must be

checked.

5.3 Alignment of pump - motor

The following information is of a general

nature. If necessary, special notes of the

coupling and motor manufacturer are to be

observed.

Before starting alignment, undo the screw fitting of

the support bracket from the adapter and motor.

Align the unit with the housing so that there is no

tension and retighten the screws.

Use supports in the direct vicinity of the bolts

foundation/base plate.

5.4 Piping

Before the pump is installed, both, the suction and

supply lines as well as the discharge line are to be

cleaned.

Dirt or damage to the sealing surfaces is best avoided

if the flange covers remain on the flanges until just

before installation.

Use flange gaskets suitable for the medium.

The screw tightening torques in Chapter 1.1 are to be

observed for tightening the flange screws.

5.4.1 Nominal size

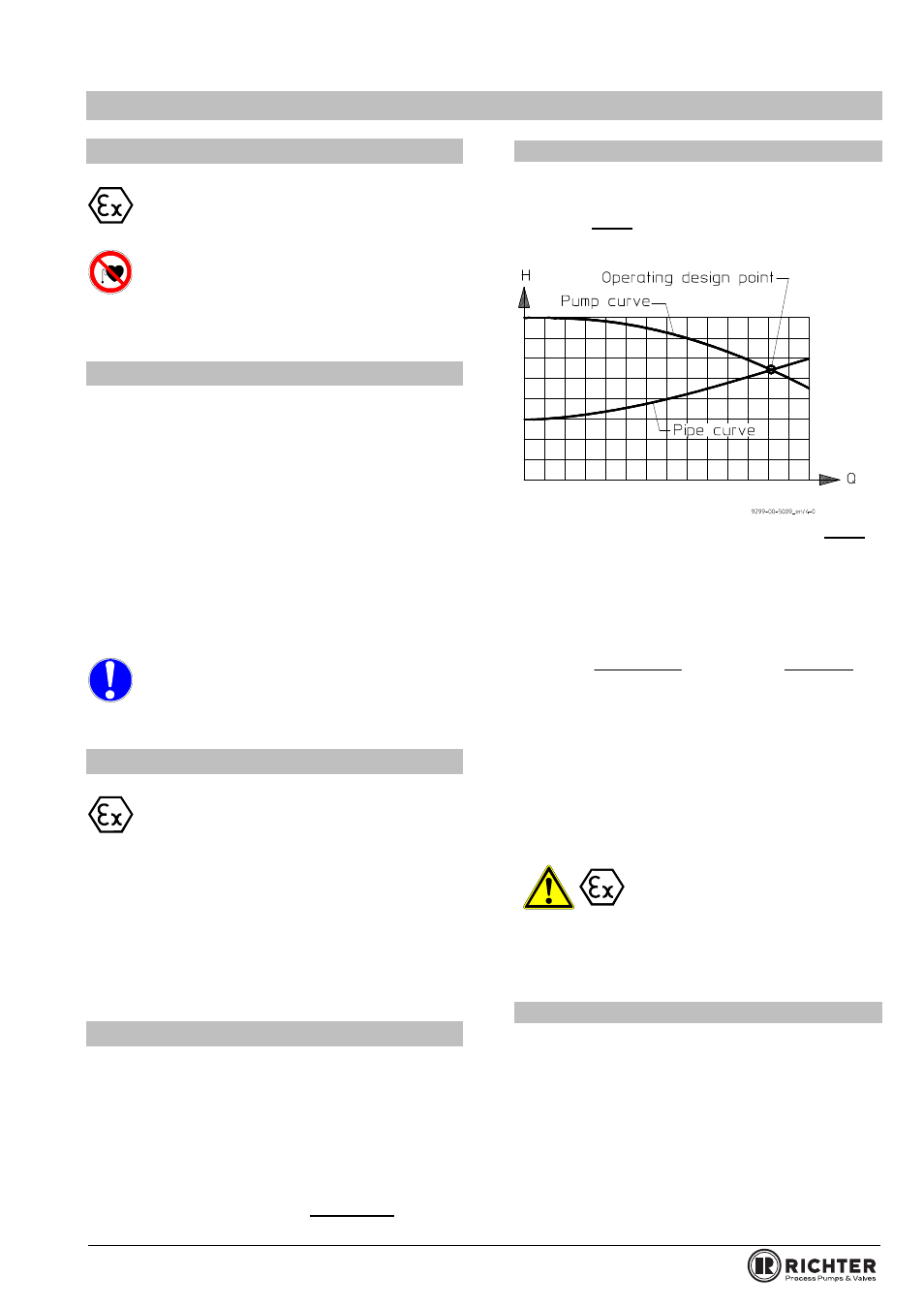

The operating design point of a centrifugal pump lies

at the intersection of the pump curve and the pipe

curve, see Fig. 2. The pump curve is provided by the

pump manufacturer. The pipe curve is determined

using diagrams or PC programs.

Fig. 2

Under no circumstances can the nominal size of the

piping be derived from the connected nominal size of

the pump.

The pipe nominal size can also be determined using

the flow rate as a rough guide.

)

ft

(

A

x

449

)

gpm

(

Q

)

s

/

ft

(

v

2

=

)

m

(

A

)

s

/

m

(

Q

)

s

/

m

(

v

2

3

=

The velocity in the suction line should not exceed

6.56 ft/s (2 m/s) and 16.4 ft/s (5 m/s) in the discharge

line.

When determining the suction line nominal size, the

NPSH value (net positive suction head) must also be

observed. The NPSHR value required for the pump

is specified in the data sheet.

The NPSHR available in the plant

should be at least 1,64 ft (0,5 m)

higher than the NPSHR required for

the pump. Otherwise, this will lead to a drop in the

delivery head, cavitation or even failure of the pump.

5.4.2 Nozzle loads

The pump can be subjected to nozzle loads in

accordance with ANSI/HI 9.6.2.

Changes in the length of the piping caused by

temperature are to be allowed for by appropriate

measures, e.g. the installation of expansion joints.