Primer strip color id chart – RCBS APS Priming Tool User Manual

Page 8

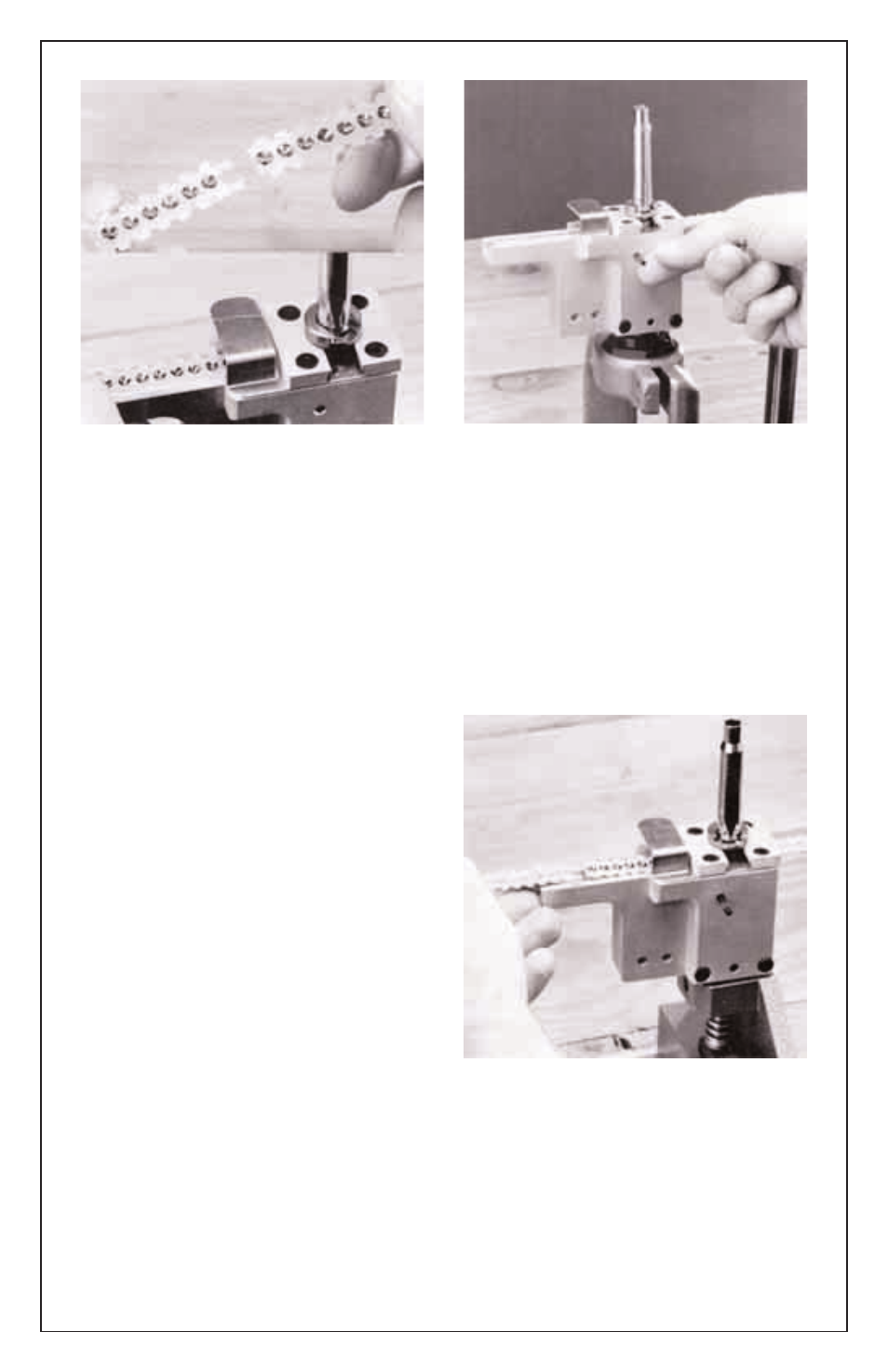

Insert a case into the shell holder and

lower the handle slowly and carefully.

The press handle should go all the

way to the bottom with very little resis-

tance. Remember you have the

mechanical advantage of compound

leverage. More than enough lever-

age to crush primers, bend the

primer plug and bend the rim of

the case – so don’t force it! If the

handle stops part way down, insert

the cam lock pin. The cam lock pin will

stop the strip from advancing while

making this adjustment. See photo

#14. Then lift the handle back up and

turn the adjustment rod in the shell

holder depth adjustment assembly

down a little and try again. When the

handle travels easily to the bottom

of its stroke, check the primer seating

depth. For high primers, back the

adjustment rod out a little. If the primer

cup is flattened (crushed), turn the

adjustment rod down a little further

until you get the correct seating depth.

When the proper priming seating

depth is achieved (flush – .004 deep)

with the handle all the way down,

remove the cam lock pin. Then raise

the handle and tighten the 1/4-28

lock nut.

You’re now ready to prime cases.

Remember, the primer strips are

designed to connect to each other.

So for continuous primer feeding,

just connect another strip onto the

end of the strip in the tool when there

is at least one inch of the ramp avail-

able to support the new strip. See

photo #15. The strip can be removed

at any point in the process by push-

ing or pulling the strip through the

right-hand side of the tool.

PRIMER STRIP COLOR ID

CHART

APS Primer Strips are color-coded to

prevent confusion and misidentifica-

tion. To minimize the number of colored

primer strips, we not only used the

8

Photo #14

Photo #15

Photo #13