RCBS Cowboy Dies User Manual

Page 9

a sized case in the

shell holder and

run it into the

expander die. The

case mouth should

be expanded and

flared (belled) just

enough to accept

the bullet when

placed on top of

the case. The expander is tapered and may be adjusted for

more or less flaring (belling) by loosening the lock ring

on top of the die and turning the expander up or down.

BULLET SEATING AND CRIMPING FOR

ROLL CRIMP

IMPORTANT: Please read instructions carefully. Do not

adjust the seater die down against the shell holder as it will distort or crush the

case. If the bullet you are using has a crimping groove, the bullet can be seated

and crimped using the following instructions. Before proceeding, cases must be

trimmed to the same overall length to assure a consistent crimp. The crimping

feature is machined into the seater die body. It is not a special attachment to

the seater plug. The die must be moved up or down to obtain the proper crimp

adjustment. To adjust, the seater die, place a sized, primed and powder-charged

case into the shell holder and run it to the top of the press stroke.

Screw the seater die into the press until you feel it touch the mouth of the

case. Back the die up one full turn and set the large lock ring. This will leave a

gap between the bottom

of the die and the shell

holder. Next, lower the

case and insert a bullet

in the case mouth.

Slowly run the case and

bullet into the seater die.

Check the bullet for

proper seating depth. If

the bullet is not seated

properly, adjust the

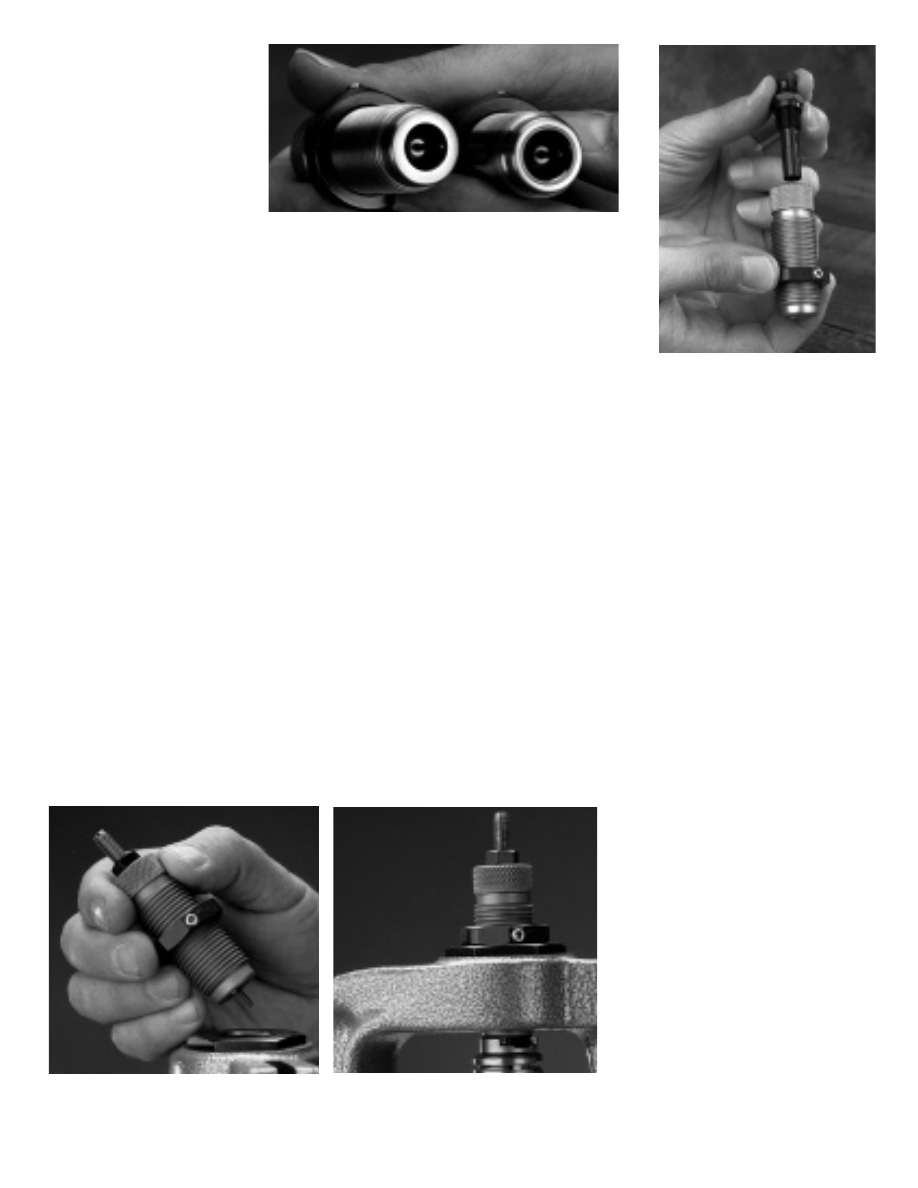

Screw the sizer die into the

reloading press.

Notice the sizer die is adjusted so

it contacts the shell holder.

The standard RCBS steel die is shown on

the left. The carbide insert is visible in the

carbide sizer die on the right.

Seater dies in our 3-die sets

use a “through-the-top”

style seater plug as shown

above.This allows for easy

cleaning.