Kenco Engineering Weld Pad Flat Glass Level Gauge User Manual

Page 2

Page 2

GAUGE CONSTRUCTION

WELDING INSTRUCTIONS

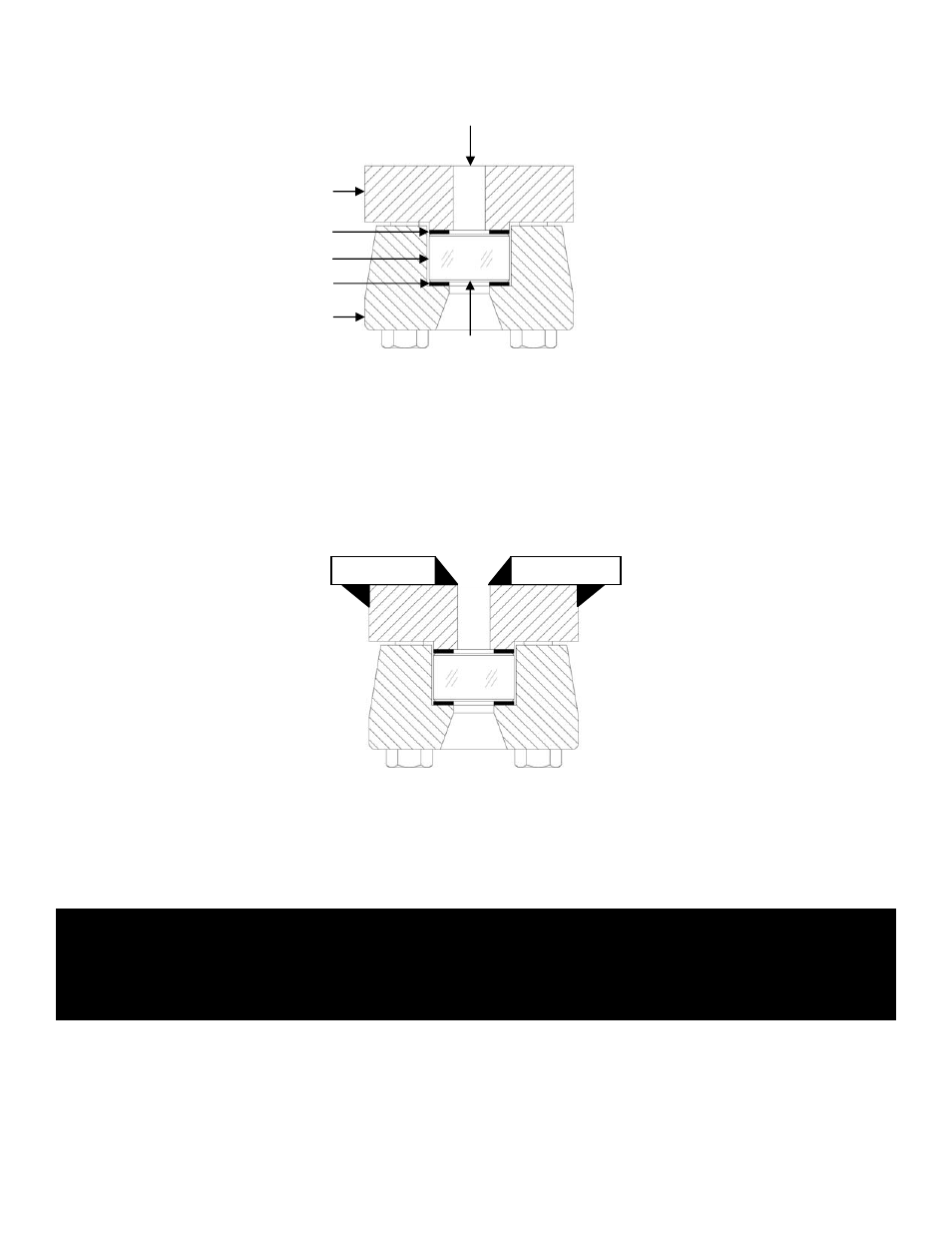

Weld Pad Gauges are shipped loosely assembled and should first be entirely dismantled. The pad may then be used as

a template for laying out the vision slot which is to be cut through the wall of the vessel. If internal welding is to be

performed (recommended), the width and length of the slot can be increased by chalking a second cutout line ¼” away

from the scribed line obtained in tracing the vision slot. This will provide a suitable shelf in which to lay the bead, as

shown in the following drawing

To avoid buckling, the pad should be tack welded at intervals, both internally and externally, in accordance with

recognized welding procedures, before placing the continuous welds. As an added precaution against distortion, the

welding pad gauge can be assembled without gaskets, using a steel spacer instead of the gasket-glass-cushion

assembly. This spacer can be cut from bar stock 1¼” X ¾”. The length will be determined by the length of the gasket

recess. This procedure will increase the rigidity of the pad and minimize the possibility of distorting the glass seating

surface.

Weld Pad Gauge (Model KWR & KWT)

Gasket

Glass

Cushion

Cover

Glass

Reflex or Transparent

Chamber

Vessel Slot

CAUTION – Standard weld pad gauges will withstand loadings due to the pressure within the gauge itself, but

they are not designed to replace the vessel strength lost when the vessel wall is cut. Kenco has

no control over the loading which the vessel will impose on the pad. It is therefore impossible to

rate welding pad gauges. The vessel fabricator must provide suitable vessel wall reinforcement

to prevent the pad from being distorted during welding, or while under operating conditions.