Kenco Engineering Flat Glass Level Gauge User Manual

Page 4

Page 4

•

The glass should not be in contact with any metal surfaces.

•

For transparent gauges used in steam service, use mica shields between the glass and gasket on the

chamber (process) side.

F.

Reassembly Procedure

To avoid leakage and undue stresses on the glass, we recommend the following reassembly procedure:

1.) Before reassembly, clean the gauge chamber seats and cover seats thoroughly with a soft metal scraper,

preferably brass. Be sure all burrs and bits of old gasket are removed. Gouged or scarred seats should be

refinished in a milling machine (or you can return the chamber to Kenco for refinishing). Damaged seats cause

low gasket compression and leakage.

2.) Locate the glass centrally in chamber and cover seat, to avoid glass-metal contact at the ends or sides. This is

best done with the gauge horizontal on a bench, If the gauge must be reassembled in a vertical position. Use a

rubber band around the sides and ends of the glass. This will prevent glass-metal contact during assembly.

3.) With a torque wrench, replace the gauge covers as follows:

a.) Clean bolt and nut threads, and apply a light oil to the threads and nut face. For gauges operating at more

than 150°F, use Molykote or a similar molybdenum disulfide lubricant.

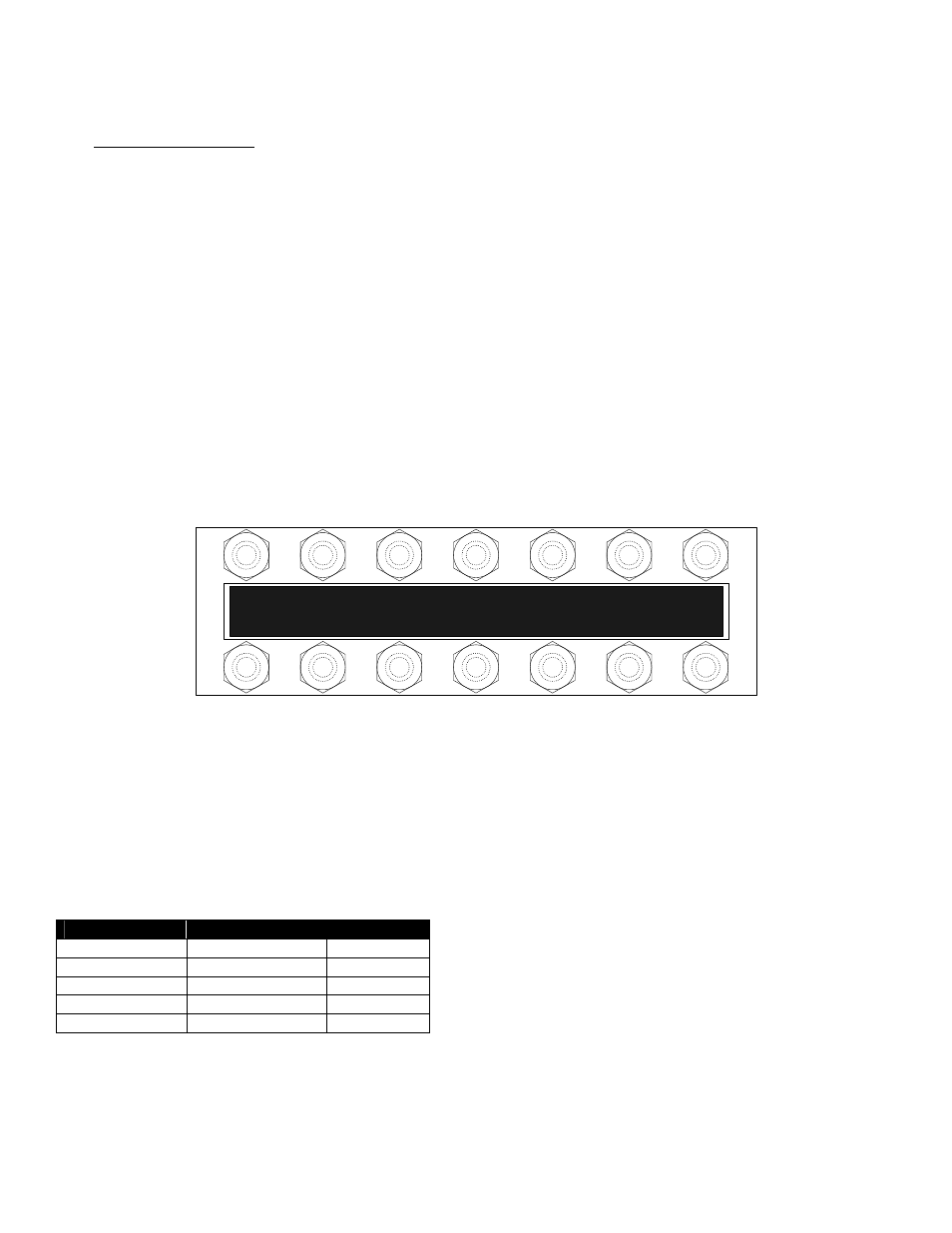

b.) Tighten the nuts finger-tight in the sequence shown in the sketch below, and then tighten with a torque

wrench in the same sequence. Tighten the nuts in five-pound stages. This procedure produces even

loading of the glass.

c.) Recommended final torque values.

•

KMR & KMT – 32ft./lbs.

•

KHR & KHT – 40ft./lbs.

d.) New rubber-bonded gaskets tend to become permanently compressed after a short time in service. This

causes slight leaks or apparent loosening of the bolts. Therefore, re-torque to the original value after the

gauge has been in service for a few hours, using the same sequence as before.

RECOMMENDED SPARE PARTS

Part

Commissioning

Two Years

Glass

5%

10%

Shields (if used)

5%

10%

Gaskets

5%

10%

Cushions

5%

10%

Bolts/Nuts

5%

10%

12

14

5

9

6

10

1

3

7

11

13

2

4

8