Kenco Engineering Flat Glass Level Gauge User Manual

Page 2

Page 2

GAUGE CONSTRUCTION

BEFORE YOU INSTALL THE GAUGE

Consider the following:

•

To avoid imposing piping strains on the gauge chamber, connect and mount the gauge so that it does not support

the piping.

•

Differential thermal expansions between the vessel and gauge can impose severe mechanical loads on the

gauge, especially if the vessel contains hot or cryogenic liquids. To prevent these, install an expansion loop

between the gauge and vessel, or use a reasonably long run of piping.

•

Support brackets should be considered for gauges over four feet in length or over 100 pounds in weight,

especially when the gauge is exposed to vibration. These support brackets will prevent overloading the

connecting valves and piping and prevent damage to the gauge from excessive vibration.

•

Always provide shutoff valves between the gauge and vessel. Kenco automatic ball check valves are

recommended to provide protection against physical injury and loss of product if glass breakage should occur.

These valves also provide a means to isolate the gauge for maintenance.

•

Bolt torque is vital to the proper operation of a flat glass gauge. Because gaskets compress over time, bolt torque

should be checked before the gauge is installed (see MAINTENANCE). Bolt torque should also be checked after

the first few hours of operation.

OPERATION

Always warm up the gauge slowly when it is used with a vessel containing a hot fluid. Slowly open the shutoff valves

carefully, and wait until the gauge is fully warmed up before completely opening the valves. Kenco Gauges use tempered

glass, designed to withstand thermal shock. However, additional loads that you cannot measure are imposed on the

glass during installation. Resistance to thermal shock is reduced accordingly. This procedure also applies to cold fluids.

During system shutdown, it is best to leave the shutoff valves open so that as the gauge cools it depressurizes along with

the rest of the system. Keeping valves closed during shutdown can trap high pressure liquid in the gauge. For high

pressure / temperature applications a viewing system of mirrors should be used to protect personnel from physical injury

in the event of glass breakage.

Gauges should be isolated periodically and bolt torque checked to prevent leaks. This is especially important on gauges

used in intermittent operation, or varying service conditions. When putting a gauge into service always check for leaks

and be certain the shutoff valves are fully open with all vents and drains closed before leaving the site.

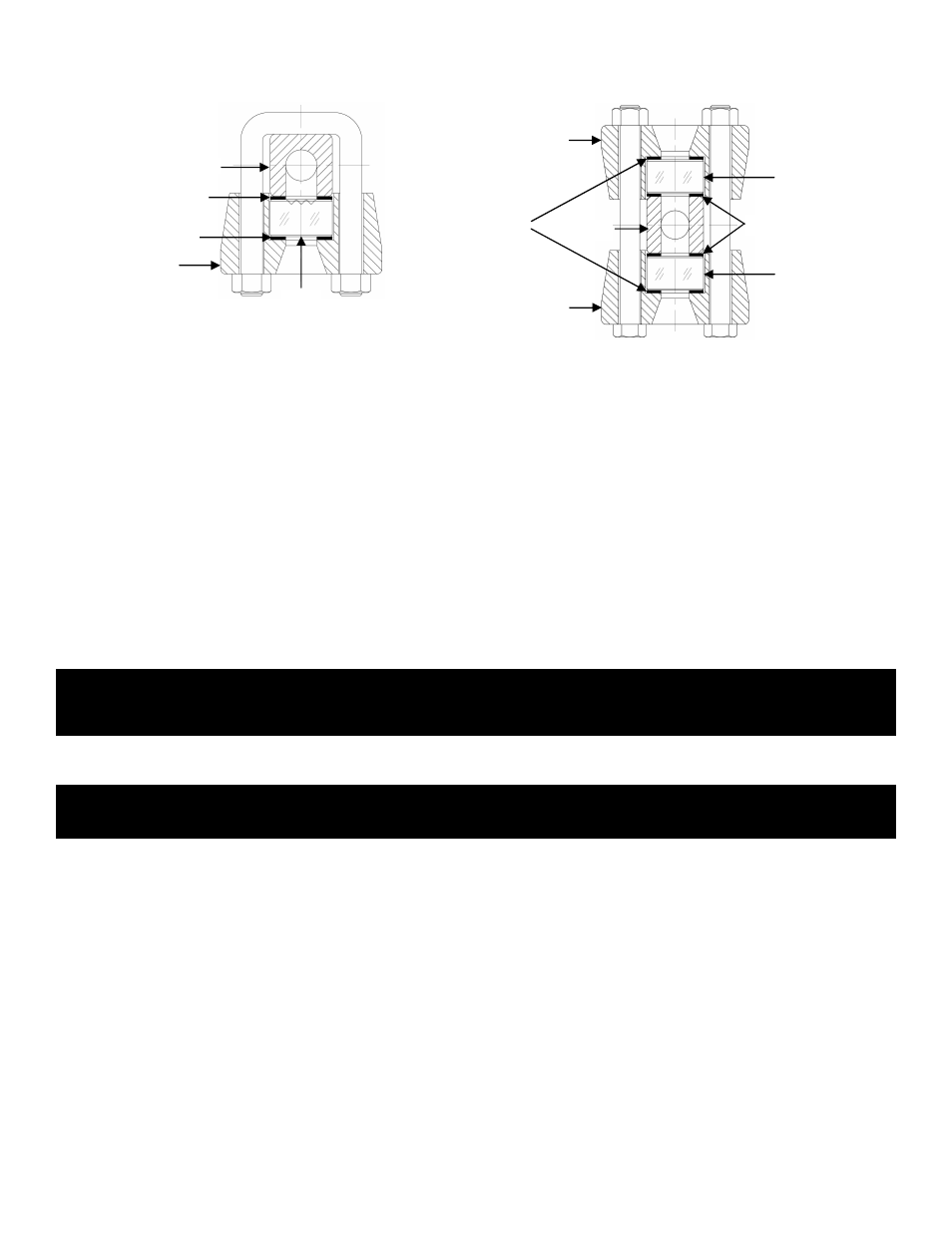

Glass

Cover

Chamber

Reflex Gauge (Model KMR & KHR)

Gasket

Cushion

Transparent Gauge (Model KMT & KHT)

Chamber

Gasket

Cushion

Cover

Glass

Cover

Glass

CAUTION – Gauges should always be isolated from the process system by closing the upper and lower

isolation valves, and draining the gauge to relieve pressure before doing any torque or

maintenance checks.

CAUTION – Rapid opening of connecting valves can cause glass breakage and / or possible injury to

personnel. Gauges should be brought into service slowly.