Kenco Engineering KUST Switch User Manual

Page 4

TROUBLESHOOTING

Problem

Solution

Check wiring; verify that the correct input

voltage is applied

Verify that liquid is filling the sensor gap

Check for dense foam or dried product in

the gap. Switch may not function properly

if either condition exists.

Check sensor phono plugs for a good

connection. Unplug and Re-plug each

connection.

No output change with level change

Check for excessive aeration in process

fluid. This is particularly important in

viscous fluids.

Check wiring; verify that the correct input

voltage is applied

Check for turbulence. Relocate switch or

isolate from turbulence

The output is “chattering”

Check for excessive aeration in process

fluid. This is particularly important in

viscous fluids.

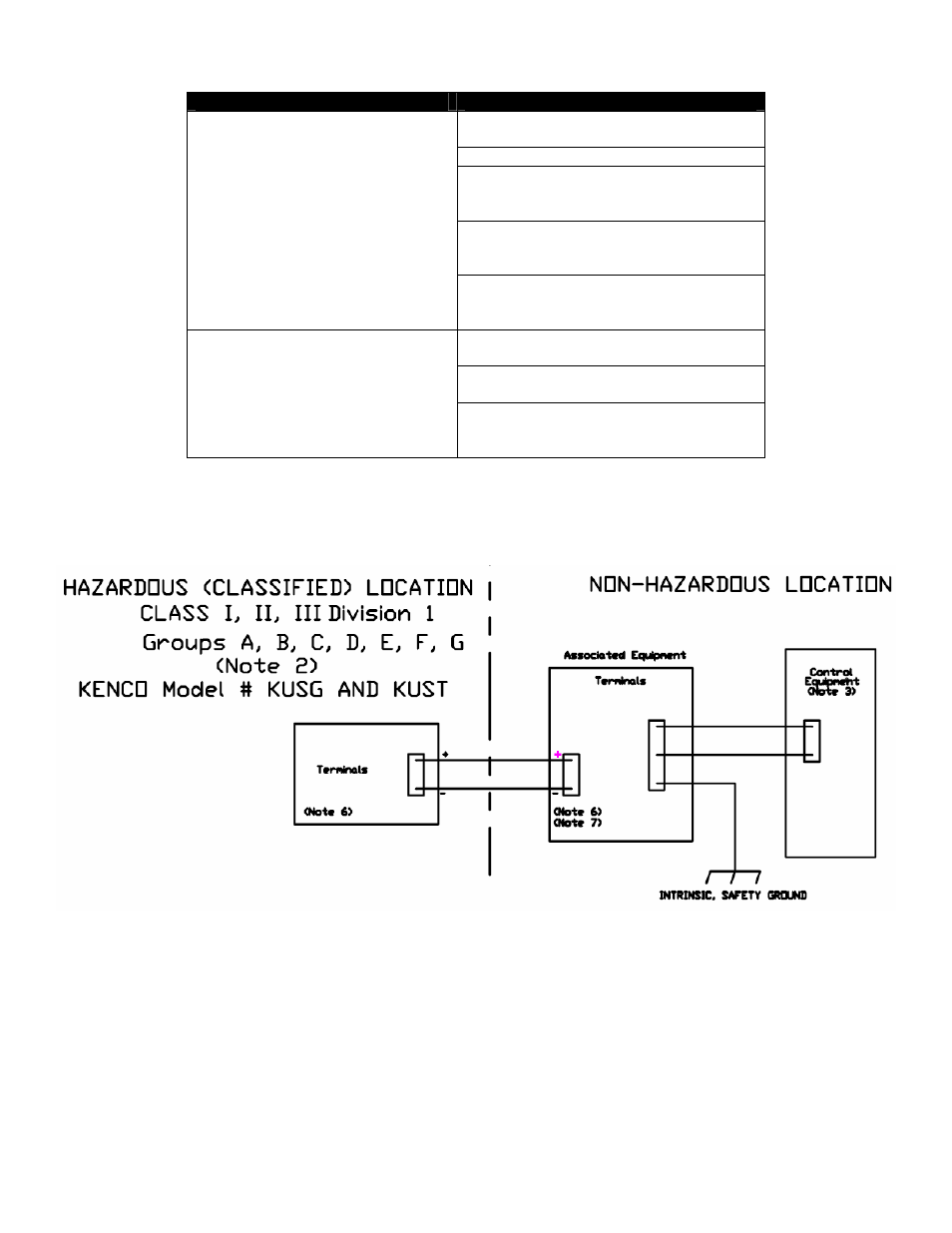

INTRINSICALLY SAFE CONTROL DRAWING

Entity Parameters:

Vmax = 36Vdc

Imax = 150mA

Ci = 0µF

Li = 54µH

NOTES:

1) Vmax > Voc; Imax > Isc; Ci + Ccable < Ca; Li + Lcable < La

2) Dust-tight conduit seal must be used when installed in Class II and Class III environments.

3) Control equipment connected to barrier must not use or generate more than 250V.

4) Installation should be in accordance with the CEC, Part 1.

5) No revision to drawing without prior CSA approval.

6) Associated equipment must be CSA Certified.

7) Associated equipment manufacturer’s installation drawing must be followed when installing this equipment.

8) For wiring refer to installation / operation manual.