Servicing the relief valve, Servicing first & second check valves, 3" (8 – 80mm) – Watts LFU009 User Manual

Page 3: Notice

3

Servicing the Relief Valve

Series 009 and LF009

1

⁄

4

" – 3" (8 – 80mm)

1. Remove the four or six relief valve cover bolts while holding the

cover down.

2. Lift the cover straight off. The stem and diaphragm assembly will

normally remain with the cover as it is removed. The relief valve

spring will be free inside the body at this point.

3. The relief valve seat is located at the bottom of the body bore,

and can be removed, if necessary, for cleaning. The disc can be

cleaned without disassembly of the relief valve module. If it is

determined that the relief valve diaphragm and/or disc should be

replaced, the relief valve module can be readily disassembled

without the use of special tools.

NOTE: The disc rubber is mold-

ed into the disc holder and is supplied as a disc holder assembly.

4. To reassemble the relief valve, press the seat firmly into place in

the body, center the spring on the seat, and insert the cover and

relief valve module as a unit straight into the bore. Press down

on the cover to assure proper alignment. Insert and tighten bolts.

NOTICE

If cover will not press flat against body, stem assembly is

crooked and damage can result. Realign stem and cover before

bolts are inserted.

NOTE: No special tools required to service Series 009 2

1

/

2

" – 3"

(65 – 80mm).

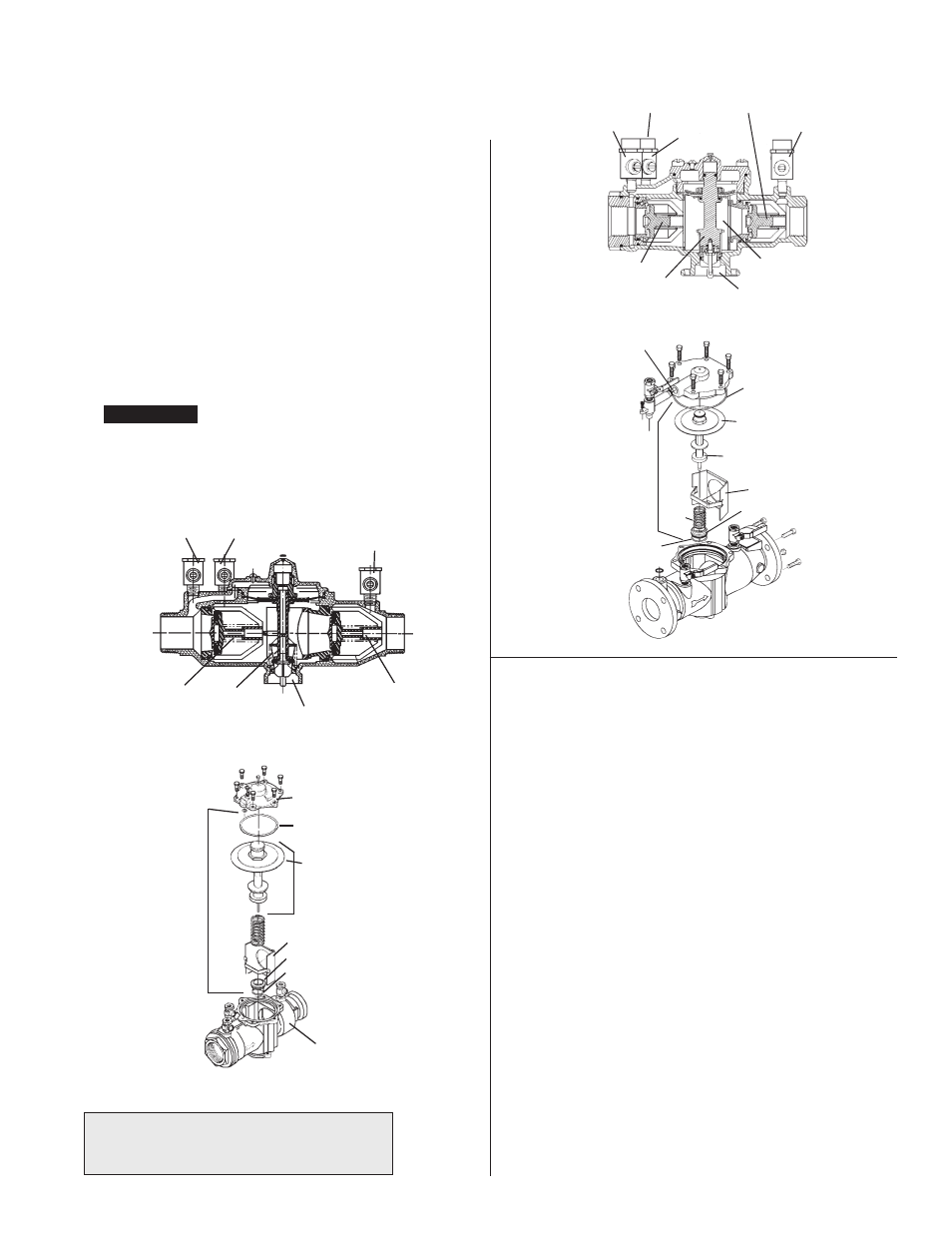

Cover

Cover O-ring

Diaphragm

Stem & Diaphragm

Assembly

Retainer

Seat

Seat O-ring

Body

Relief V

alve

Service Parts Kit

Test Cock No.3

Test Cock No.2

Test Cock No.4

First Check

Module

Assembly

Second

Check Module

Assembly

Relief Valve

Assembly

Water Outlet

Test Cock No. 2

Test Cock No. 3

Test Cock No. 4

Ball Type

Test Cocks

Second Check

Module Assembly

R.P. Zone

Water Outlet

Relief Valve

Assembly

First Check

Module Assembly

Cover O-ring

Diaphragm

Stem Assembly

Retainer

Seat

Seat O-ring

Relief V

alve Service

Parts Kit

Spring

Flow Tube O-ring

1. Remove the relief valve assembly as outlined on page 3.

2. Remove the retainer from the body bore. The check valve mod-

ules can now be removed from the valve by hand or with a

screwdriver.

NOTE: The seats and springs of the first and second check

modules are not in ter change able. The heavier spring and smaller

diameter seat belong with the first check module.

3. The check seats are attached to the cage with a bayonet type

locking arrangement. Holding the cage in one hand, push the

seat inward and rotate coun ter clock wise against the cage. The

seat, spring cage, spring and disc assembly are now individual

com po nents.

4. The disc assembly may now be cleaned and re as sem bled or,

depending on its condition, may be dis card ed and replaced with

a new assembly from the repair kit. O-rings should be cleaned or

replaced as necessary and lightly greased with the FDA

approved silicon grease. For more information refer to repair

parts price list PL-RP-BPD.

5. Reassemble the check valve modules. Check modules are

installed in the valve body with the seat facing the valve inlet. The

modules must be securely in place before the retainer can be

replaced. Replace relief valve assembly.

NOTE: No special tools required to service Series 009 2

1

⁄

2

" – 3"

(65 – 80mm)

Servicing First & Second

Check Valves

Series 009 and LF009

1

⁄

4

" – 3" (8 – 80mm)

For repair kits and parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts

price list PL-RP-BPD found on

www.watts.com.