Available models prefix, Materials, Pressure — temperature – Watts U009 User Manual

Page 2: Standards, Approvals, Air gaps and elbows, Notice

Available Models

Prefix:

U – union connections

Suffix:

QT – quarter-turn ball valves

S

– bronze strainer

LF – without shutoff valves

AQT –

3

⁄

4

" – 2" (20 – 50mm) only, elbow fittings for 360° rotation

PC – internal polymer coating

SH – stainless steel ball valve handles

Note: The installation of a drain line is recommended. When install-

ing a drain line, an air gap is necessary (see ES-AG/EL/TC).

Materials

Body: Bronze

Discs: Silicone rubber

Check Seats: Replaceable polymer

Relief Valve Seat: Removable stainless steel

Cover Bolts: Stainless steel

Pressure — Temperature

Maximum Working Pressure: 175psi (12 bar)

Temperature Range: 33°F – 180°F (0.5°C – 82°C)

Standards

USC Manual 8th Edition

†

ASSE No. 1013

AWWA C511

CSA B64.4

IAPMO File No. 1563.

† Does not indicate approval status. See below for approved models.

Approvals

ASSE, AWWA, CSA, IAPMO

Approved by the Foundation for Cross-Connection Control and

Hydraulic Research at the University of Southern California.

Approved models QT, AQT, PC.

UL Classified (Models with LF Suffixes)

A

B

A

B

* Epoxy coated

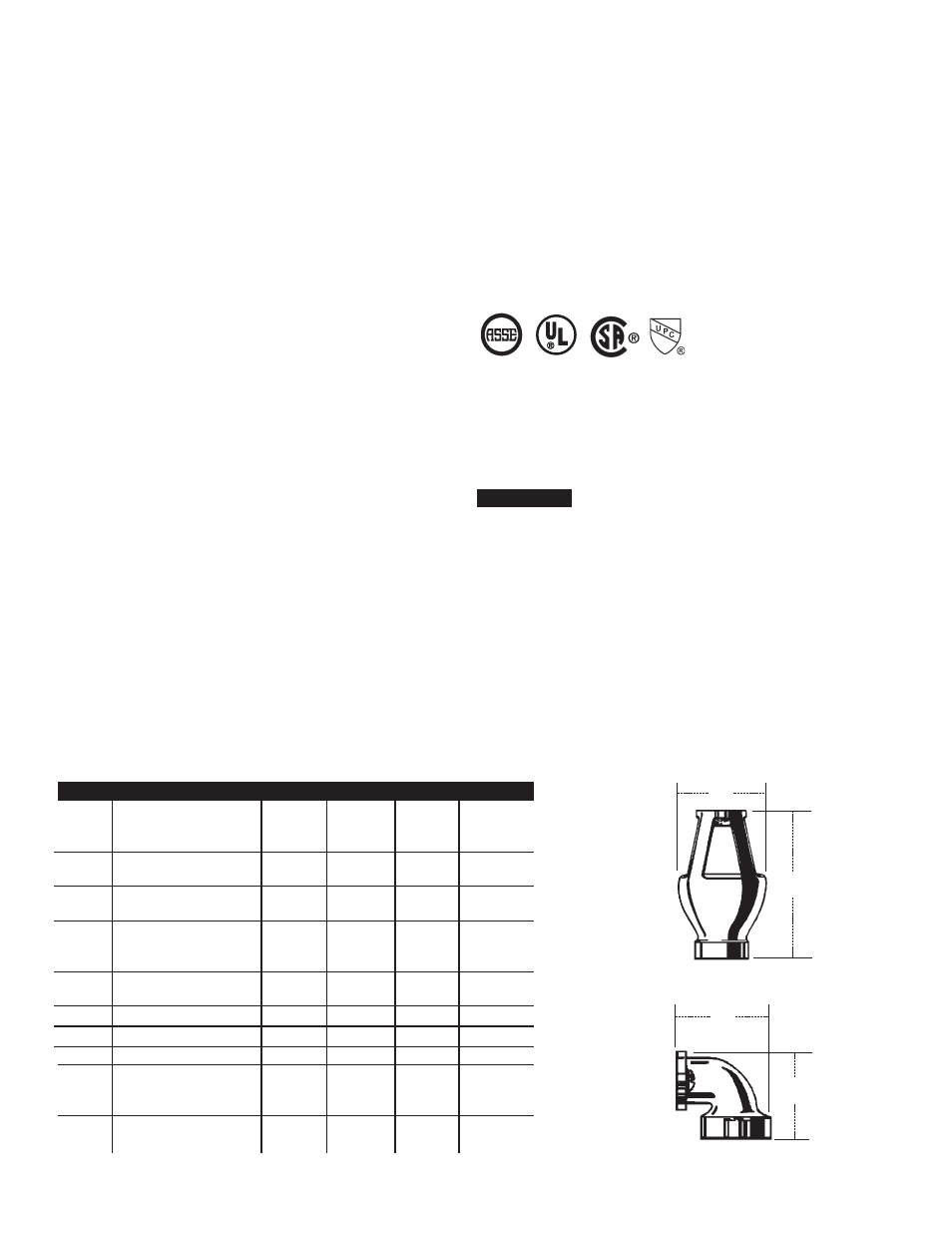

Air Gaps and Elbows

model

drAin outlet

dimensions

Weight

for 909, U009

A

B

and 993 sizes

in. mm in. mm in. mm lbs. kgs.

909AGA

1

⁄

4

"–

1

⁄

2

" 009,

1

⁄

2

13 2

3

⁄

8

60 3

1

⁄

8

79 .625 .3

3

⁄

4

" 009M2/M3

909AGC

3

⁄

4

"–1" 009/909,

1

25

3

1

⁄

4

83 4

7

⁄

8

124 1.50 .7

1"–1

1

⁄

2

" 009M2

909AGF

1

1

⁄

4

"–2" 009M1,

2

51

4

3

⁄

8

111 6

3

⁄

4

171 3.25 1.5

1

1

⁄

4

"–3" 009/909,

2" 009M2, 4"–6" 993

909AGK

4"–6" 909,

3

76

6

3

⁄

8

162 9

5

⁄

8

243 6.25 2.8

8"–10" 909M1

909AGM

8"–10" 909

4

102 7

3

⁄

8

187 11

1

⁄

4

286 15.50 7.0

909ELA

1

⁄

4

"–

1

⁄

2

" 009,

3

⁄

4

"

009M2/M3

– – – – – – – –

909ELC

3

⁄

4

"–1" 009/909

–

–

2

3

⁄

8

60 2

3

⁄

8

60 .38 .2

* 909ELF

1

1

⁄

4

"-2" 009M1,

–

–

3

5

⁄

8

92 3

5

⁄

8

92 2 .9

1

1

⁄

4

"–2" 009/909,

2" 009M2, 4"–6" 993

* 909ELH

2

1

⁄

2

"–3"

009/909 – – – – – – – –

Vertical

NOTICE

Inquire with governing authorities for local installation requirements