Testing, Double check valve assemblies, Test no. 2 - test no. 2 check valve – Watts 774 User Manual

Page 7: Test no. 1 - test no. 1 check valve

Test No. 2 - Test No. 2 Check Valve

1. Install high side hose between TC #3 and tester

connection A.

2. Install low side hose between TC #4 and tester

connection B.

3. Open TC #3 then VA, bleed hose, then close VA.

4. Open TC #4 then VB, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1. Open TC #1

and bleed by loosening hose connection at VB. Tighten

hose connection, fully open VB.

Push - Start Test

6. Close shutoff valve #1.

7. Slowly open VA and lower high side pressure about -2 psi

below the low side pressure (differential reading about -2.0

psi). Close VA. If reading is maintained, record as “tight”.If

reading returns to 0 and the pressure A increases to pres-

sure B, the check is recorded as leaking. If the reading re-

turns to + psi, No. 2 shutoff valve is leaking excessively,

and must be replaced to test the valve.

Push - Stop Test.

7

The following Test Procedure is one of several that is recognized

throughout the United States for verification of the functioning of

Backflow preventers.

The following procedure is not a specific recommendation.

The Watts series of test kits are capable of performing any

of the recognized Backflow test procedures.

A. Flush all test cocks.

B. Turn tester on (before connecting hoses). Tester must

read all zeroes. Close VA and VB.

Test No. 1 - Test No. 1 Check Valve

1. Install high side hose between TC #2 and tester

connection A.

2. Install low side hose between TC #3 and tester

connection B.

3. Open TC #2 then VA, bleed hose, then close VA.

4. Open TC #3 then VB, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1. Open TC #1

and bleed by loosening hose connection at VB. Tighten

hose connection, fully open VB.

Push - Print Head (wait) then Push - Star Test

6. Close shutoff valve #2 then #1.

7. Slowly open VA and loser high side pressure about -2 psi

below the low side pressure (differential reading about -2.0

psi). Close VA. If reading is maintained, record as “tight”.

If reading returns to 0 and the pressure A increases to

pressure B, the check is recorded as leaking. If the reading

returns to + psi, No. 2 shutoff valve is leaking excessively,

and must be replaced to test the valve.

8. Close all test cocks, remove hoses from TC #2 and TC #3

and TC #1. reopen shutoff valve #1. Proceed to Test No.2.

Push - Stop Test.

It is important that this device be tested periodically in compliance

with local codes, but at least once per year or more as service condi-

tions warrant. If installed on a fire sprinkler system all mechanical

checks, such as alarm checks, single checks and backflow preventers

should be inspected internally every one to five years in accordance

with NFPA 13 A and NFPA 25

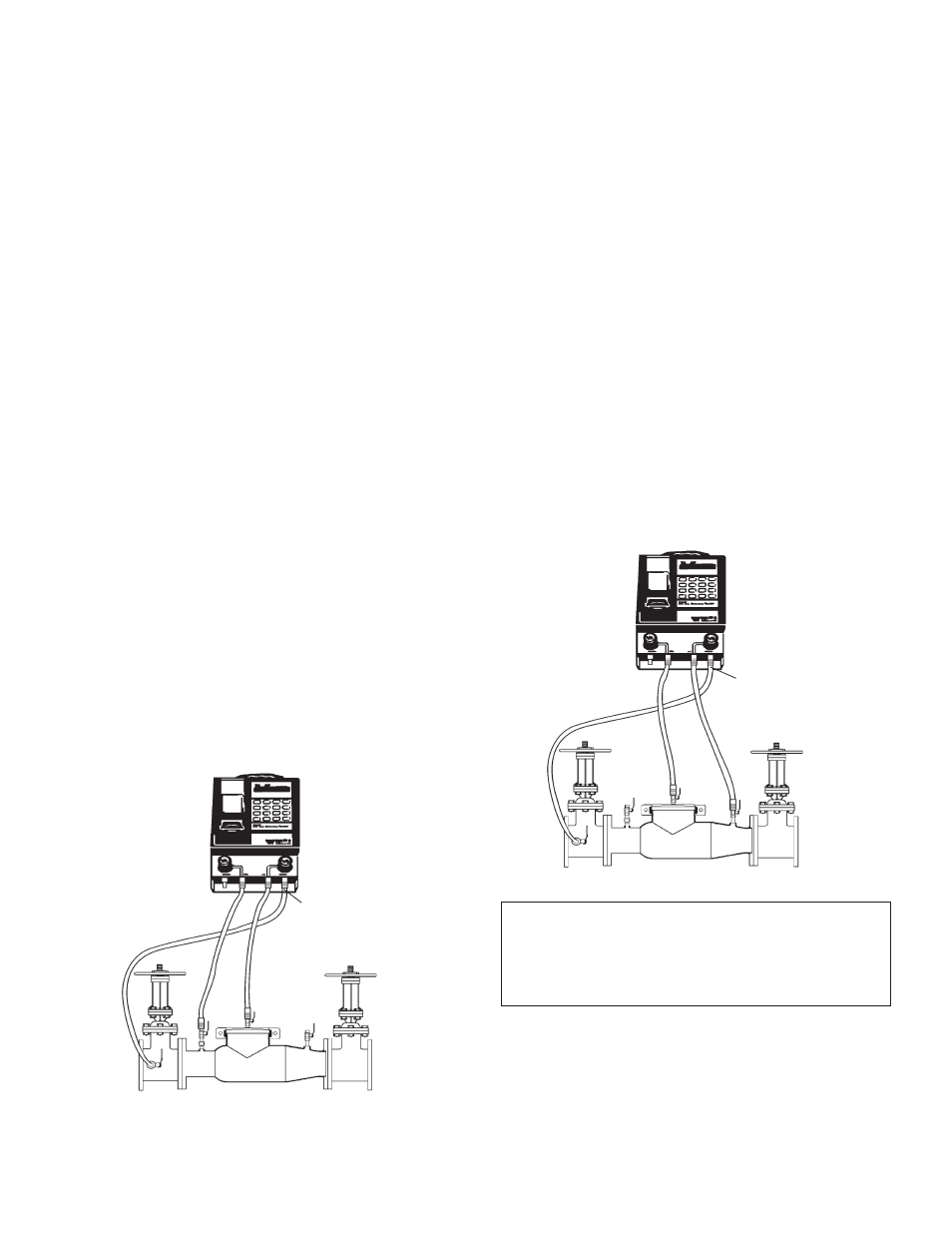

Testing

Double Check Valve Assemblies

Watts 774

Watts TK-DP

Test 1

VA

VB

Watts 774

Watts TK-DP

Test 2

VA

VB

For additional testing information send for IS-TK-DP/DL, IS-TK-9A

and IS-TK-99E