Removing cam-checks – Watts 774 User Manual

Page 6

6

774/774DCDA Repair Kits

EDP NO

KIT NO.

SIzE

in.

mm

First or Second Check Kit

0888827

RK 774/774DCDA CK 4

8, 10, 12 200, 250, 300

774/774DCDA

Kits include: Complete Check with Check O-ring.

Cover Kit

0888828

RK 774/774DCDA C

8, 10, 12 200, 250, 300

774/774DCDA

Kits include: Cover, Grooved Coupler & Gasket.

Watts assemblies require minimum maintenance. All assemblies must be retested once maintenance has been performed.

(Before servicing be certain shut off valves are closed)

Check Studs

Check Studs

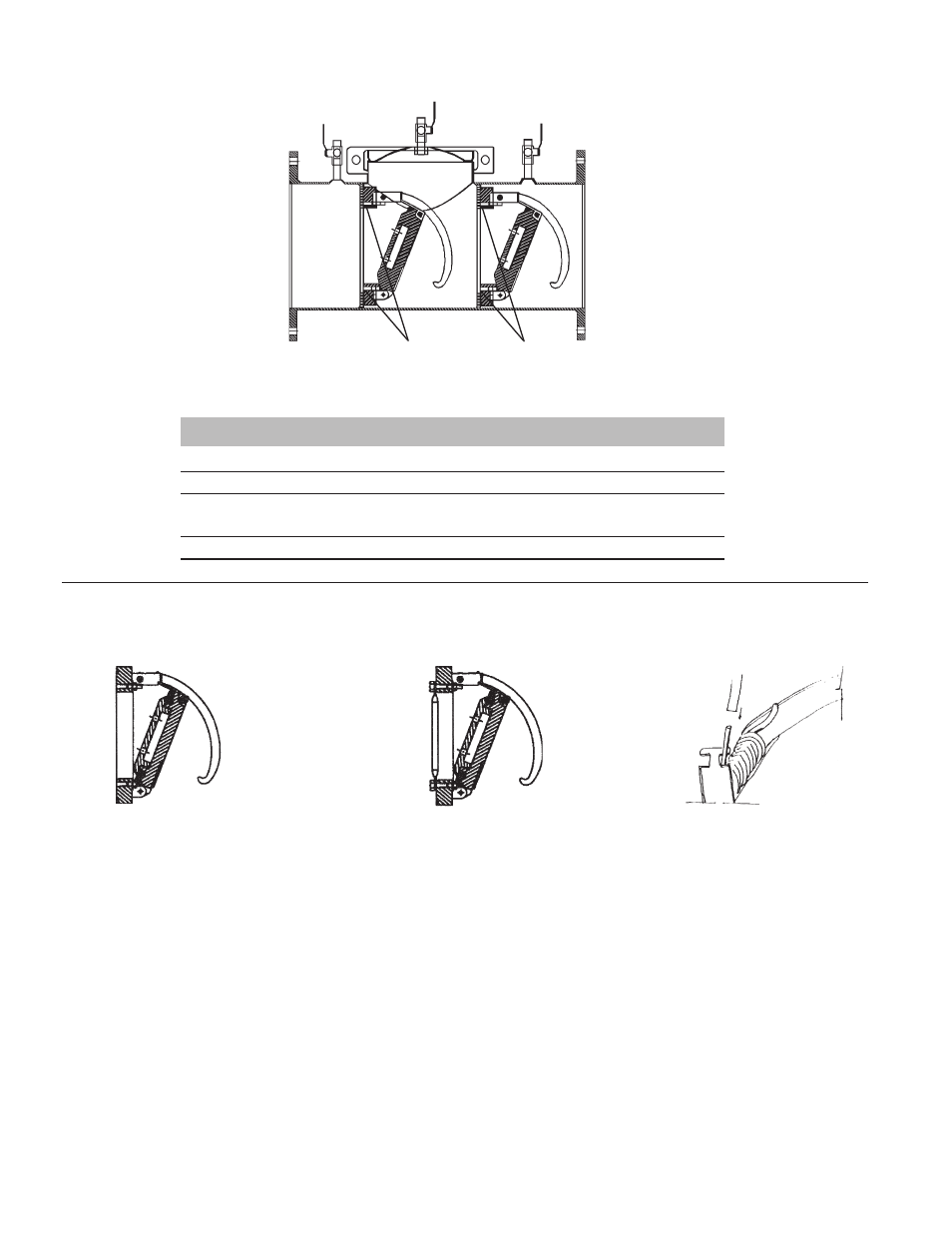

#1 Cam-Check Figure 2

#2 Cam-Check Figure 3

Figure 4

Watts Series 774/744DCDA 8"- 12"

Servicing and Second Checks

Removing Cam-Checks

1. Shut down water system and lock out system if possible.

Slowly open all ball valves to relieve air and water pressure.

Loosen bolts on groove coupler and remove groove couple

and cover plate from valve body

2. #1 Check (Fig.2) Using a

9

⁄

16

" socket wrench or nut driver, re-

move the four nuts from the #1 check studs (See fig. 1) Using

two hands, place them at 12 o'clock and 6 o'clock, wiggle

the check assembly free. Remove through access port with

back of clapper first with back of clapper first with spring end

down. Pull check assembly out of main body.

#2 Check (Fig.3) After loosening bolts with a

9

⁄

16

" socket,

remove bolts completely, Using the centerline access bar,

spin the cam assembly from the 9 o'clock position to the 12

o'clock position, then (without letting go of the access bar)

push the cam assembly slightly downstream so that the

clapper is now parallel to the valve body. Now bring the cam

assembly through the check retaining wall. Leave the cam

assembly clapper parallel to the valve body. Pull the cam

assembly through the access port.

3. Using a

3

⁄

8

" nut driver or a piece of small diameter pipe, place

on the cam arm torsion spring and move away from and

around the torsion spring retaining bracket so as to relieve the

torsion spring tension. (See Figure 4) This will allow the cam

arm to move freely, enabling you to inspect the clapper face

and cam seat.Thoroughly clean the seat area and clapper

sealing surfaces, cam arms, and O-rings.

4. Before reinstallation of Checks thoroughly clean O-ring groove

and lubricate O-ring with F.D.A. approved lubricant.