Operational parameters, Contents of under counter system, Tools recommended for installation – Watts PWDWLCV2 User Manual

Page 3: Drill a hole for the faucet in a porcelain sink, Step 1

Operational Parameters

Installation needs to comply with state and local plumbing regula-

tions . This system is intended to be installed on the cold supply line

only .

Contents of Under Counter System

1 LCV Unit

2 Filters

1 Parts Bag

1 Faucet Assembly

If any of the items are missing, please contact Watts Premier prior to

installing.

Tools Recommended For Installation

A small knife

Variable speed drill

1

⁄

8

" (3mm),

1

⁄

4

" (6 .4 mm) and

7

⁄

16

" (11 .0mm) drill bits

1

1

⁄

4

" hole saw (for porcelain sinks) or 1

1

⁄

4

" hole punch (for stainless

steel sinks)

1

⁄

2

" and

5

⁄

8

" open-end wrenches (or adjustable wrenches)

Phillips screwdriver

3

MaxIMuM

MInIMuM

Operational Temperature

100°F (37.8°C)

40°F (4.4°C)

Operating Pressure

85psi (5.98 kg/cm²)

20psi (1.406 kg/cm²)

pH Parameters

10

5

Flow Rate

0.5 GPM @ 60 psig

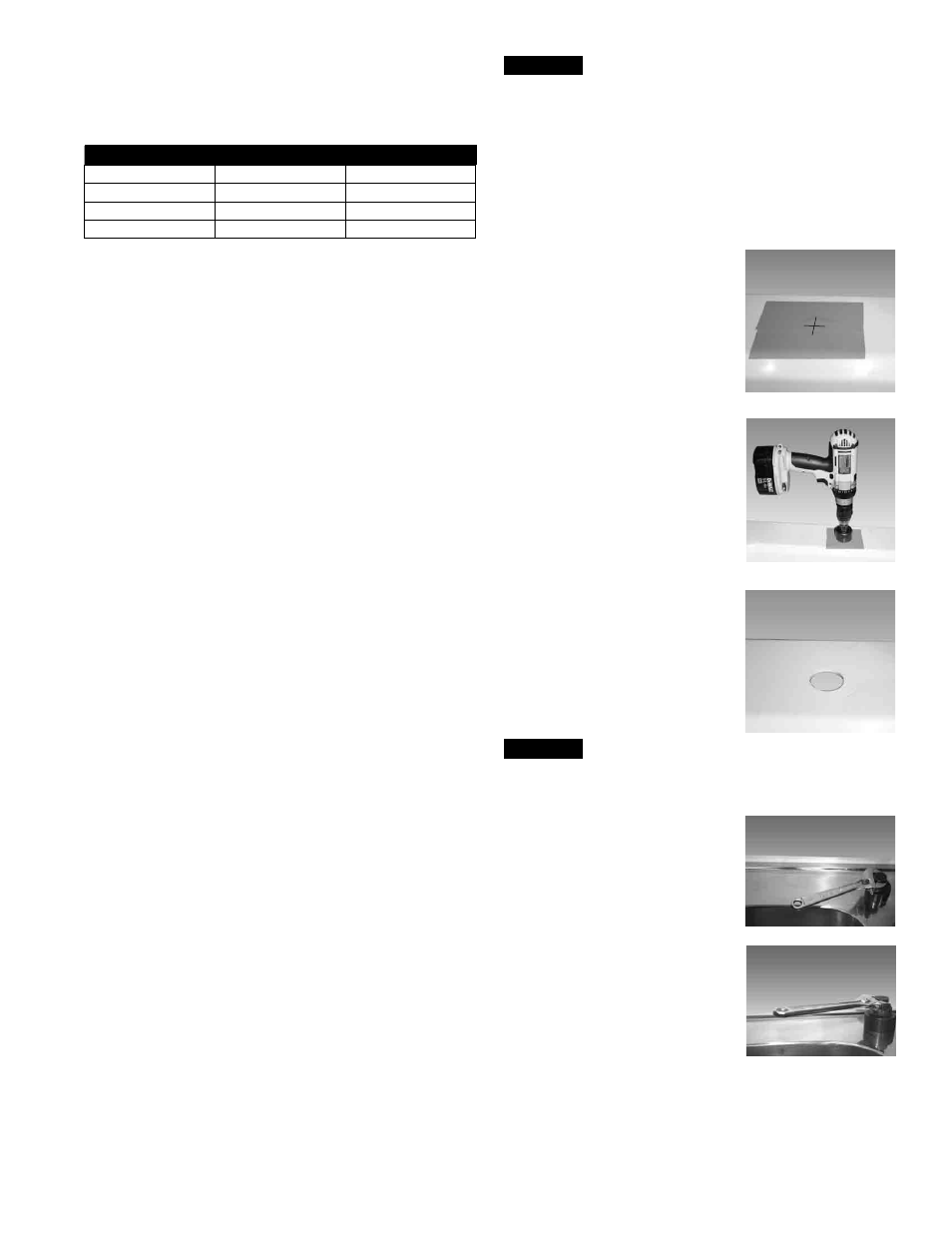

Drill a Hole for the Faucet in a Porcelain Sink

Note: Most sinks are predrilled with 1½" or 1¼" diameter hole

that you can use for your RO faucet. (if you are already using it

for a sprayer or soap dispenser, see Step 2).

Caution: Porcelain sinks are extremely hard and can crack or

chip easily.

Use extreme caution when drilling. Watts accepts no responsi-

bility for damage resulting from the installation of faucet.

Step A – Determine desired location for

the RO faucet on your sink

and place a piece of masking

tape on over where the hole is

to be drilled . Mark the center

of the hole on the tape .

Step B – Using a variable speed drill

set on the slowest speed, drill

a

1

⁄

8

“ pilot hole through both

porcelain and metal casing

of sink at the marked center

of the desired location . Use

lubricating oil or liquid soap

to keep the drill bit cool (If drill

bit gets hot it may cause the

porcelain to crack or chip) .

Step C – Using a 1¼" hole saw, pro-

ceed to drill the large hole .

Keep drill speed on the slow-

est speed and use lubricating

oil or liquid soap to keep the

hole saw cool during cutting .

Step D – Make sure the surroundings

of the sink are cooled before

mounting the faucet to the

sink after drilling and remove

all sharp edges .

STEP 1

Punch a Hole for the Faucet in a Stainless

Steel Sink

Note: If mounting faucet to a Stainless

Steel Sink you will need a 1¼" Hole

Punch. The faucet opening should be

centered between the back splash

and the edge of the sink, ideally on the

same side as the vertical drain pipe.

Step A – Drill a ¼" pilot hole . Use a

1

⁄

2

"

Hole Punch and an adjustable

wrench to punch the hole in the

sink . Change to the 1¼" Hole

Punch to enlarge the hole

The faucet can now be installed .

OR