Bryant Multipurpose Oil 369AAN User Manual

Page 6

MASONRY CHIMNEYS

This furnace can be vented into an existing masonry chimney. This

furnace must not be vented into a chimney servicing a solid fuel

burning appliance. Before venting furnace into a chimney, the

chimney MUST be checked for deterioration and repaired if

necessary. The chimney must be properly lined and sized per local

or national codes.

If furnace is vented into a common chimney, the chimney must be

of sufficient area to accommodate the total flue products of all

appliances vented into chimney.

The following requirements are provided for a safe venting

system:

1. Be sure that chimney flue is clear of any dirt or debris.

2. Be sure that chimney is not servicing an open fireplace.

3. Never reduce pipe size below the outlet size of furnace.

(See Fig. 2.)

4. All pipe should be supported using proper clamps and/or

straps. These supports should be at least every 4 ft.

5. All horizontal runs of pipe should have at least 1/4-in. per

ft of upward slope.

6. All runs of pipe should be as short as possible with as few

turns as possible.

7. Seams should be tightly joined and checked for leaks.

8. The flue pipe must not extend into chimney but be flush

with inside wall.

9. The chimney must extend 3 ft above highest point where it

passes through the roof of a building and at least 2 ft higher

than any portion of a building within a horizontal distance

of 10 ft. It shall also be extended at least 5 ft above highest

connected equipment flue collar.

10. Check local codes for any variance.

FACTORY-BUILT CHIMNEYS

Listed factory-built chimneys may be used. Refer to chimney

manufacturer’s instructions for proper installation.

E.

Oil Burner

This furnace is supplied with a high-pressure atomizing retention

head-type burner (for use with grade 1 or 2 fuel oil). The mounting

flange is fixed to burner air tube and no adjustment is required for

insertion length.

F.

Oil Connections

Complete instructions for installing fuel oil piping can be found in

oil burner Installation Instructions included with furnace.

Oil line entry holes are provided in side panels. Two holes are

provided in each location so that a 2-pipe system may be used if

desired.

An oil filter should be used with all oil burners and should be

installed as close to burner as possible.

G.

Barometric Draft Control

The barometric draft control shipped with furnace MUST be used

with furnace to ensure proper operation. Instructions for installing

control are packed with control.

H.

Electrical Connections

WARNING:

The unit cabinet must have an uninter-

rupted or unbroken electrical ground to minimize per-

sonal injury if an electrical fault should occur. A green

ground screw is provided in control box for this connec-

tion.

115-V WIRING

Before proceeding with electrical connections, make certain that

voltage, frequency, and phase correspond to that specified on unit

rating plate. Also, check to be sure that service provided by utility

is sufficient to handle load imposed by this equipment. Refer to

rating plate or Table 7 for equipment electrical specifications.

Make all electrical connections in accordance with National

Electrical Code (NEC) ANSI/NFPA 70-2001 and any local codes

or ordinances that might apply. For Canadian installations, all

electrical connections must be made in accordance with Canadian

Electrical Code CSA C22.1 or subauthorities having jurisdiction.

CAUTION:

Do not connect aluminum wire between

disconnect switch and furnace. Use only copper wire.

Failure to follow this caution will lead to intermittent

electrical operation and/or fire hazard.

The control system depends on correct polarity of power supply.

Connect HOT wire (H) and NEUTRAL wire (N) as shown in Fig.

3 or 4.

A separate line voltage supply MUST be used with a fused

disconnect switch or circuit breaker between main power panel

and unit. (See Fig. 3 or 4.)

Metallic conduit (where required/used) may terminate at side panel

of unit. It is not necessary to extend conduit inside unit from side

panel to control box.

When replacing any original furnace wiring, use only 105°C No.

14 AWG copper wire.

24-V WIRING

Instructions for wiring thermostat (field supplied) are packed in

thermostat box. Make thermostat connections as shown in Fig. 3 or

4 at 24-v terminal board on fan timer board.

ACCESSORIES

When installing optional accessories to this appliance, follow

manufacturer’s Installation Instructions included with accessory.

Other than wiring for thermostat, wire with a minimum of type

″

T

″

insulation (63°F rise) must be used for accessories.

I.

Horizontal or Downflow Installation

For horizontal installation, determine which

″

side

″

will become the

″

top

″

, when the unit is laid down. Remove the flue pipe clearance

knock-out from the top of that side panel. Install the flue elbow so

that it exits the cabinet of the furnace through that opening.

For counterflow installation, the flue pipe must exit the cabinet

through 1 of the side panel openings (as above), then extended up

the side of the furnace. Insure that adequate clearances to com-

bustibles are observed. Downflow Conversion/Vent Guard Kit

MUST be used.

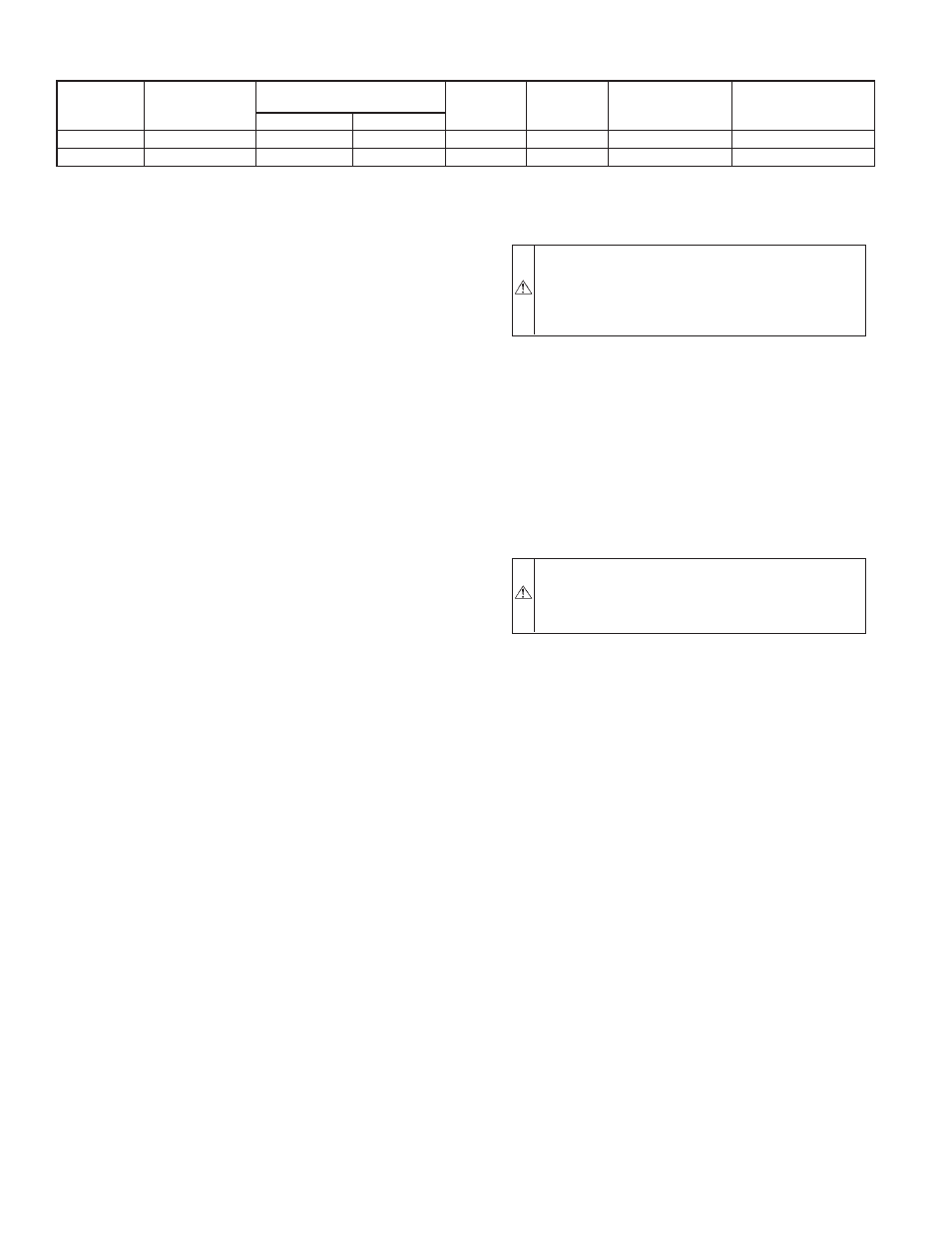

TABLE 7—ELECTRICAL DATA

UNIT

SIZE

VOLTS—

HERTZ—

PHASE—

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

MIN

WIRE

GAGE

MAX WIRE

LENGTH (FT)

MAX FUSE OR

CKT BKR AMPS

Max.*

Min.*

036105

115—60—1

132

104

12.2

14

26

15

060120

115—60—1

132

104

15.7

12

26

20

* Permissible limits of voltage range at which unit will operate satisfactorily.

† Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

‡ Time-delay fuse is recommended.

—6—