Maintenance instructions, Service relief valve, Material–tool requirements – Watts 957Z User Manual

Page 3: Instructions

3

0

20

40

60

80 psi

0

138

276

413

551 kPa

3

WARNING

!

Prior to servicing the relief valve, it is mandatory to shut

down water system by closing both the inlet and outlet

shutoff valves and relieving pressure within the assembly by

opening the #2, #3 and #4 test cocks.

DO NOT REMOVE SPIDER BUSHING FOR SERVICING

1. Disconnect the hose from the bottom cover plate to the relief

valve.

2. An O-ring seals the relief valve body to the main housing. It

is not necessary to tighten the connection beyond firm hand

tightening. The relief valve should be able to be removed by

unscrewing the relief valve from the housing.

3. Remove the cover plate of the relief valve by removing the four

connecting screws.

4. Remove the rubber diaphragm from the relief valve. Be

aware of how the diaphragm is configured so that it can be

reinstalled in the same manner. The hard rubber tab in the

diaphragm fits into a similar socket in the head of the piston.

(Figure 1)

5. Hold the relief valve in both hands with the threaded end

up and both thumbs on the head of the piston. Push up on

the piston until the piston shaft with the attached E-clip is

exposed. Remove the E-clip (Figure 2)

6. Remove the piston and spring from the relief valve hous-

ing and thoroughly clean all parts including the diaphragm.

Inspect all rubber parts for damage and if damaged, replace

them with new parts.

7. Reassemble the relief valve in the reverse order that it

was disassembled.

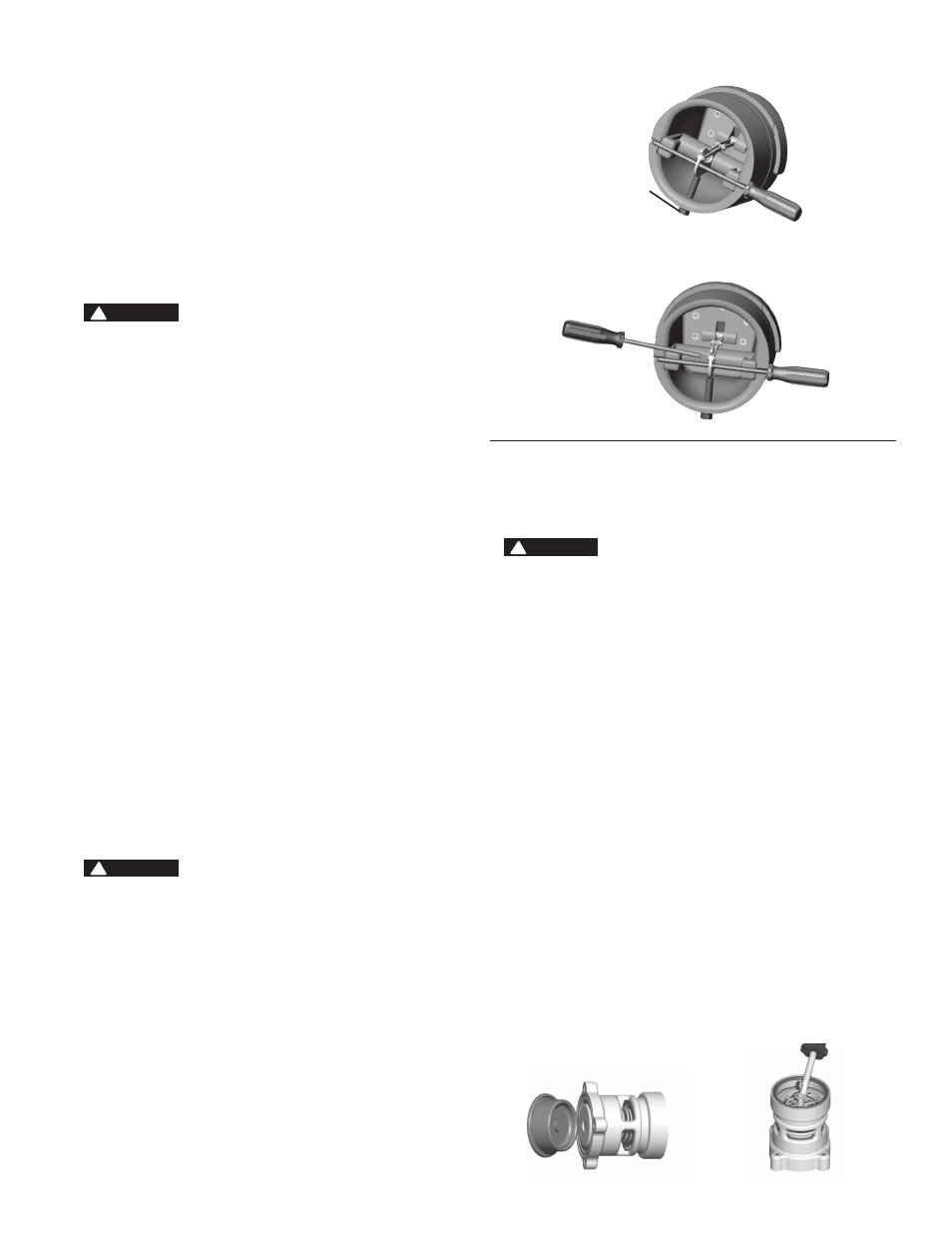

Figure 1

Figure 2

Material–Tool Requirements:

• #3 Phillips screwdriver or

5

/

16

" diameter rod, length sufficient

to span diameter of check, see Figures A and B.

•

1

/

2

– 13 x 5 fully threaded hex bolt (Service bolt).

•

3

/

4

" open end or socket wrench.

Instructions

WARNING

!

Prior to servicing any Watts valve, it is mandatory to shut

down the water system by closing both the inlet and outlet

shutoff valves. After shutoff valves are closed, open test cock

#2, #3 & #4 to relieve pressure within the backflow assembly.

1. After #3 test cock has been opened to relieve pressure, re-

move #3 test cock from housing.

When repairing an 8" or 10" (200 or 250mm) device, remove

both Victaulic couplers from body. Slide the downstream Vic-

taulic coupler gasket to the downstream side of the housing.

The upstream Victaulic coupler gasket stays in place.

2. Remove checks that are to be serviced.

3. Locate the service hole and thread in the service bolt by hand

until it contacts the linkage. (Figure A)

4. Continue to thread in service bolt with the wrench until the

service hole in the linkage is aligned with the service notches

on the spring arbors. (Figure A)

5. Insert the Phillips screwdriver through the arbors and service

hole of the linkage making sure that the tip of the screwdriver

extends past the ends of the arbors by a minimum of

1

/

4

"

(6mm). (Figure B)

6. Back out the service bolt until load is transferred to the screw-

driver. Continue to back out the service bolt until

sufficient clearance is achieved to remove the complete spring

mechanism.

7. To disconnect linkage, remove retaining clip and pin (store

in a safe location for reinstallation).

8. To remove spring mechanism, grasp the screwdriver at the

center and pull complete assembly straight out and store in

a safe place.

9. Reinstall in reverse order of these instructions.

WARNING

!

While the spring mechanism is removed for check servicing;

never pull the screwdriver out or off the support notches on the

arbors. Doing so may cause bodily injuries.

Maintenance Instructions

Series 957, 957RPDA, LF957RPDA

8" – 10" (200 – 250mm)

Service Relief Valve

Series 957, 957RPDA, LF957RPDA

Figure B

Figure A

Service Hole