Maintenance instructions, Installation instructions – Watts 957Z User Manual

Page 2

2

WARNING

!

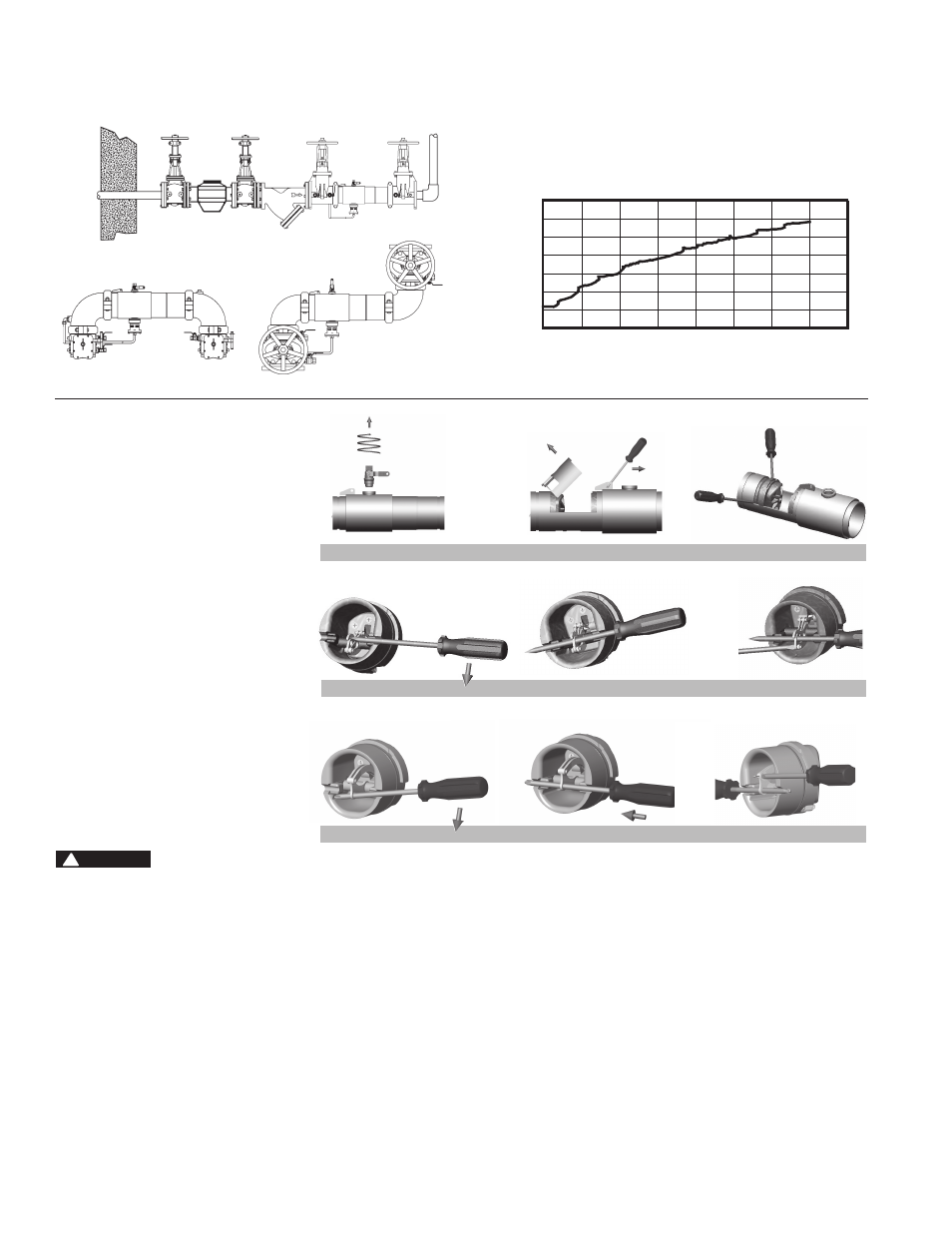

Prior to servicing any Watts valve, it is mandatory to shut down

the water system by closing both the inlet and outlet shutoff

valves. After shutoff valves are closed, open test cock #2, #3

and #4 to relieve pressure within the backflow assembly.

1. After #3 test cock has been opened to relieve pressure,

remove #3 test cock from housing. (Figure A)

2. Insert a #3 screwdriver through the hole on the top of the

cover sleeve and using both hands rotate the cover sleeve

approximately

1

⁄

4

-turn clockwise and

1

⁄

4

-turn counter-clock-

wise to break the sleeve O-ring seals. Using the screwdriver,

slowly slide the cover sleeve to the downstream side of the

housing. (Figure B)

3. Remove the stainless steel check retainer from the housing.

(Figure B)

4. Remove the #1 check module (Figure C) by inserting two flat

blade screwdrivers into the slots on either side of the check

module and gently pry the check module toward the open

zone.

5. Remove #2 check module with the same instructions as in #4

above. For servicing 6" (150mm) checks see 8" – 10" (200 –

250mm) instructions on p. 4.

6. To clean or inspect either check module, insert a #3 screw-

driver through the downstream side of the check module as

shown in Figure D and E. When the screwdriver is in place,

remove the E-clip (Figure F) and pin connecting the structural

members and the check clapper will open with no tension.

7. Thoroughly clean the seating area. The sealing disc may be

removed, if necessary, by removing the screws connect-

ing the keeper plate to the clapper. The sealing disc may be

reversed and reinstalled if the elastomer is cut or damaged.

8. Wash check module and O-ring and inspect for any damage.

If damaged, reinstall new parts.

9. After thorough cleaning, lubricate O-ring w/FDA approved lu-

bricant, replace pin and E-clip in structural members, remove

screw driver and reinstall check modules and assemble hous-

ing in reverse order of these instructions.

Maintenance

Instructions

Series 957, 957RPDA,

LF957RPDA

2

1

⁄

2

" – 6" (65 – 150mm)

Relief Valve Discharge Rates 2

1

⁄

2

" – 10" (65 - 250mm)

957, 957RPDA and LF957RPDA

lpm gpm

1330 350

1140 300

950 250

760 200

570 150

380 100

190 50

0 0

0

20

40

60

80 psi

0

138

276

413

551 kPa

Rate of Flow

Pressure

Horizontal Installation

N Pattern

Z Pattern

Figure A

Figure B

Figure C

Figure D

Figure E

Figure F

#2 Check Diagrams

Figure D

Figure E

Figure F

#1 Check Diagrams

Installation Instructions

Series 957, 957RPDA, LF957RPDA