Watts R24-12-1111000 User Manual

Page 23

III. SERVICE

AND

MAINTENANCE

The 3501 Reverse Osmosis Controller is designed for ease of maintenance and

minimum service. Since the highest quality of electronic semiconductor

components are used in this design, it is not likely that circuit malfunctions or

failures will occur. It is our recommendation that service be limited to identifying

malfunctions at the board level and that component level troubleshooting be

referred to the factory.

Field failures that most frequently occur are:

- Improper or broken wiring connections

- Incorrect wiring of the motor starter

- Improper

grounding

- Cable run is too long

- Water in connectors

- Dirty

probes

- Defective

probes

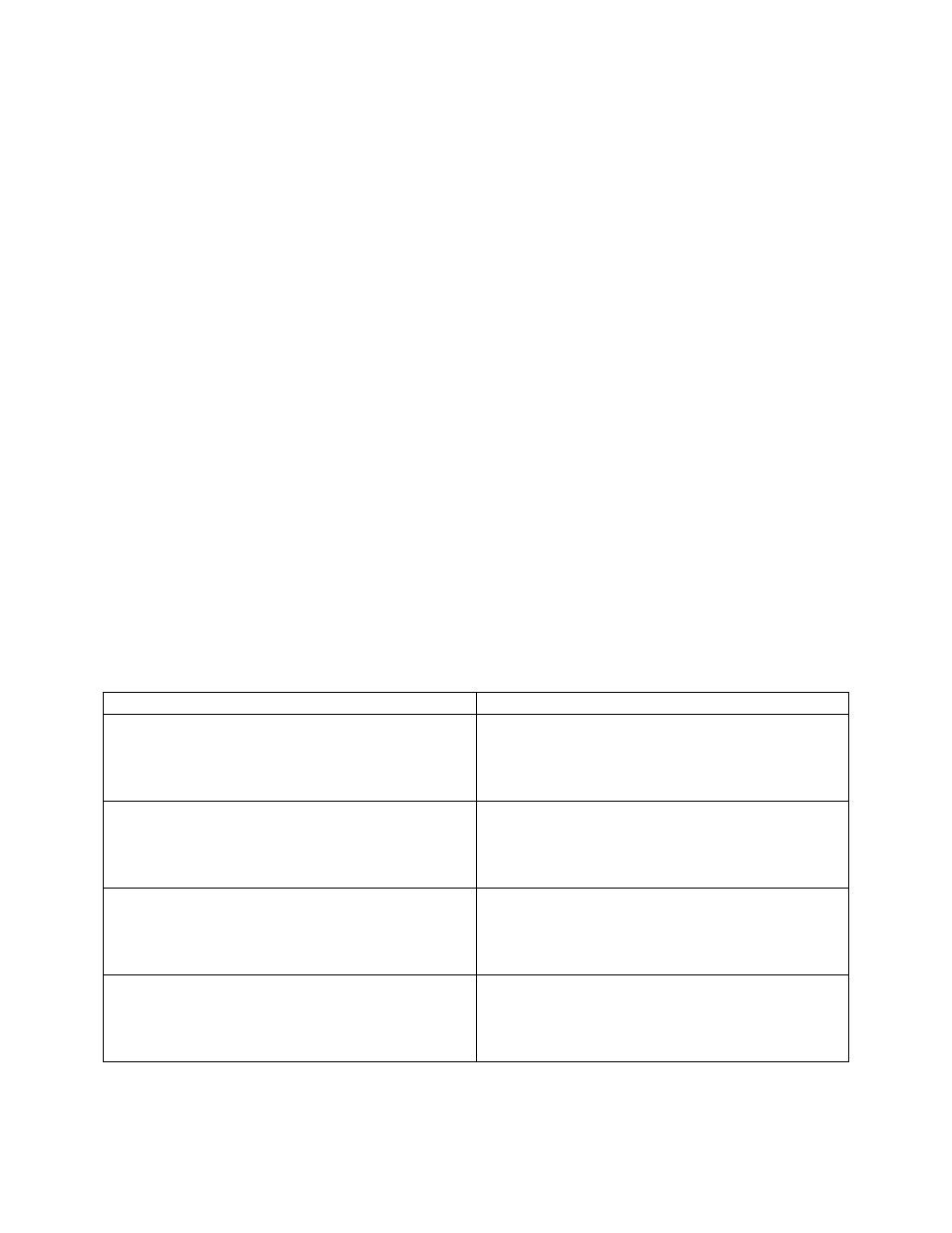

A. Troubleshooting

Description of Problem

Possible Cause or Solution

System shuts down on low pressure but

pressure is okay.

1. Check the pressure switch set point

2. Possible short in wiring to pressure switch

3. Defective pressure switch

4. Orifice in pressure switch may be plugged

Pressing the Start/Stop button does not turn the

system on.

1. Verify that the key switch is on

2. Verify that the circular connector on the

bottom of the controller is attached

3. Check the fuse in the power inlet

Conductivity monitor does not display the

proper reading.

1. Calibrate the controller

2. Check the wiring to the conductivity probe

3. Clean the conductivity probe

4. Replace the conductivity probe

Erratic conductivity display

1. Conductivity probe wiring may be too

close to high voltage lines.

2. Check for moisture in the connection

between the probe and the lead wire.