Bryant DURAPAC PLUS 581A User Manual

Page 30

—

30

—

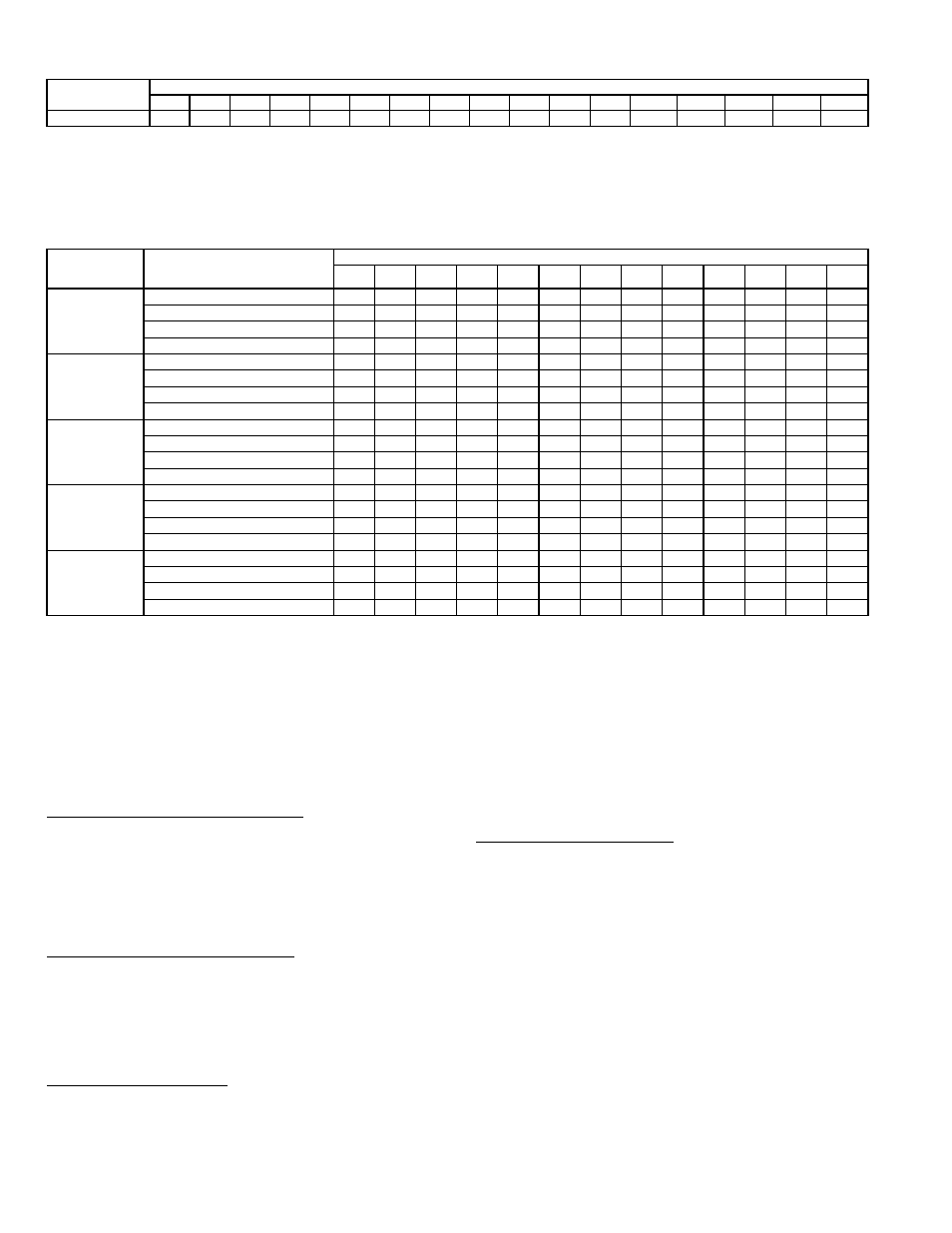

Table 26 — Accessory/FIOP Static Pressure (in. wg)*

LEGEND

*The static pressure must be added to the external static pressure. The sum and the evaporator entering-air cfm should then be

used in conjunction with the Fan Performance tables to determine blower rpm and watts.

Table 27 — Fan Rpm at Motor Pulley Settings*

*Approximate fan rpm shown.

XII. OPTIONAL ECONOMI$ER IV

See Fig. 23 for EconoMi$er IV component locations. The

optional EconoMi$er IV comes from the factory fully wired

and assembled. No field wiring or assembly is required for

standard outdoor dry bulb changeover operation. Field wir-

ing of accessory sensors is required for different operational

modes.

A. EconoMi$er IV Standard Sensors

Outdoor Air Temperature (OAT) Sensor

The outdoor air temperature sensor (HH57AC074) is a 10 to

20 mA device used to measure the outdoor-air temperature.

The outdoor-air temperature is used to determine when the

EconoMi$er IV can be used for free cooling. The sensor is

factory-installed on the EconoMi$er IV in the outdoor air-

stream. See Fig. 23. The operating range of temperature

measurement is 40 to 100 F.

Supply-Air Temperature (SAT) Sensor

The supply-air temperature sensor is a 3 K thermistor

located at the outlet of the indoor fan. See Fig. 24. This sen-

sor is factory installed. The operating range of temperature

measurement is 0° to 158 F.

The temperature sensor is a short probe with blue wires

running to it.

Outdoor Air Lockout Sensor

The EconoMi$er IV is equipped with an ambient tempera-

ture lockout switch located in the outdoor airstream which is

used to lock out the compressors below a 42 F ambient

temperature.

B. EconoMi$er IV Controller Wiring and Operational Modes

Determine the EconoMi$er IV control mode before set up of the

control. Some modes of operation may require different sensors.

Refer to Table 28. The EconoMi$er IV is supplied from the

factory with a supply-air temperature sensor and an

outdoor air temperature sensor. This allows for operation of

the EconoMi$er IV with outdoor air dry bulb changeover

control. Additional accessories can be added to allow for dif-

ferent types of changeover control and operation of the

EconoMi$er IV and unit.

Outdoor Dry Bulb Changeover

The standard controller is shipped from the factory config-

ured for outdoor dry bulb changeover control. The outdoor

air and supply-air temperature sensors are included as

standard. For this control mode, the outdoor temperature is

compared to an adjustable set point selected on the control.

If the outdoor-air temperature is above the set point, the

EconoMi$er IV will adjust the outdoor-air dampers to mini-

mum position. If the outdoor-air temperature is below the set

point, the position of the outdoor-air dampers will be con-

trolled to provide free cooling using outdoor air. When in this

mode, the LED next to the free cooling set point potentiome-

ter will be on. The changeover temperature set point is con-

trolled by the free cooling set point potentiometer located on

the control. The scale on the potentiometer is A, B, C, and D.

See Fig. 25 for the corresponding temperature changeover

values.

COMPONENT

CFM

4,000

4,500

5,000

5,500

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

10,500

11,000

11,500

12,000

EconoMi$er IV

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

0.11

0.12

0.13

0.15

0.16

0.17

0.19

0.20

FIOP

—

Factory-Installed Option

581A

UNIT

SIZE

DRIVE

MOTOR PULLEY TURNS OPEN

0

1

/

2

1

1

1

/

2

2

2

1

/

2

3

3

1

/

2

4

4

1

/

2

5

5

1

/

2

6

210

(208/230 and

460 volt)

Low Range Vertical

647

667

687

707

727

747

767

786

806

826

846

866

886

High Range Vertical

897

917

937

958

978

998

1018

1038

1058

1079

1099

1119

1139

Low Range Horizontal

896

924

951

979

1006

1034

1062

1089

1117

1144

1172

1199

1227

High Range Horizontal

1113

1138

1163

1188

1213

1238

1264

1289

1314

1339

1364

1389

1414

210

(575 volt)

Low Range Vertical

810

832

854

876

897

919

941

963

985

1007

1028

1050

1072

High Range Vertical

873

893

912

932

951

971

991

1010

1030

1049

1069

1088

1108

Low Range Horizontal

863

886

909

933

956

979

1002

1025

1048

1072

1095

1118

1141

High Range Horizontal

1042

1062

1083

1103

1123

1143

1164

1184

1204

1224

1245

1265

1285

240

(208/230 and

460 volt)

Low Range Vertical

949

970

992

1013

1035

1056

1078

1099

1120

1142

1163

1185

1206

High Range Vertical

941

961

980

1000

1019

1039

1059

1078

1098

1117

1137

1156

1176

Low Range Horizontal

1113

1138

1163

1188

1213

1238

1264

1289

1314

1339

1364

1389

1414

High Range Horizontal

1096

1116

1137

1157

1177

1197

1218

1238

1258

1278

1299

1319

1339

240

(575 volt)

Low Range Vertical

949

970

992

1013

1035

1056

1078

1099

1120

1142

1163

1185

1206

High Range Vertical

941

961

980

1000

1019

1039

1059

1078

1098

1117

1137

1156

1176

Low Range Horizontal

1113

1138

1163

1188

1213

1238

1264

1289

1314

1339

1364

1389

1414

High Range Horizontal

1096

1116

1137

1157

1177

1197

1218

1238

1258

1278

1299

1319

1339

300

(all voltages)

Low Range Vertical

941

961

980

1000

1019

1039

1059

1078

1098

1117

1137

1156

1176

High Range Vertical

1014

1038

1061

1085

1108

1132

1156

1179

1203

1226

1250

1273

1297

Low Range Horizontal

941

961

980

1000

1019

1039

1059

1078

1098

1117

1137

1156

1176

High Range Horizontal

1014

1038

1061

1085

1108

1132

1156

1179

1203

1226

1250

1273

1297