Banner T-GAGE M18T Series Temperature Sensors User Manual

Apc-18 air purge collar for 18 mm sensors, Features, Installation

Printed in USA

07/05

P/N 123618

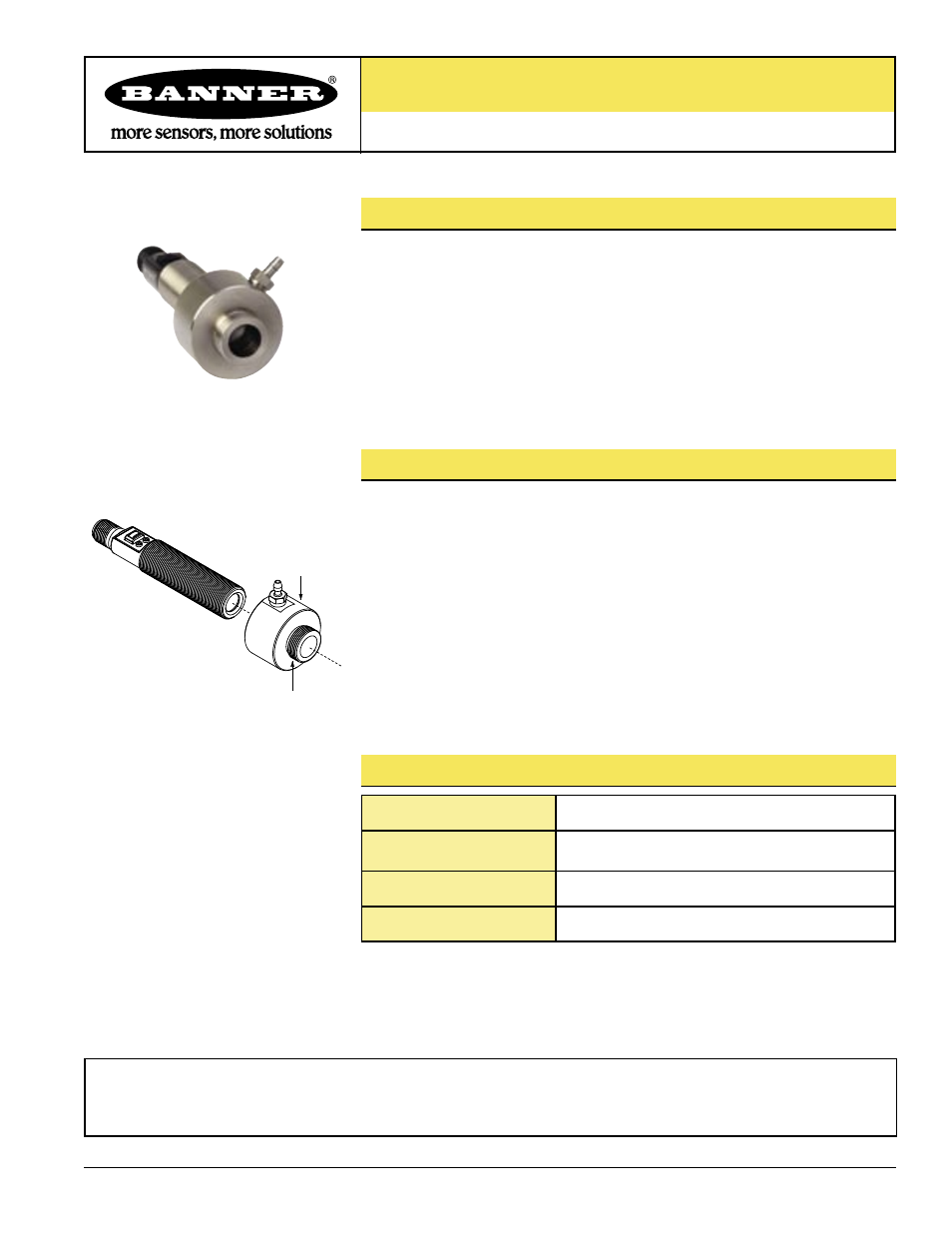

APC-18 Air Purge Collar for 18 mm Sensors

For use with 18 mm threaded-barrel sensors

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: [email protected]

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair

or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other

warranty either expressed or implied.

Features

• Positive air pressure prevents water, dust, and other airborne contaminants from

collecting on the sensor face.

• Air flow helps cool sensors affected by ambient heat in the sensing environment.

• Works with many of Banner’s 18 mm threaded-barrel photoelectric and temperature

sensors.

NOTE: Because air temperature affects the speed of sound, the APC-18 Air Purge

Collar should not be used with ultrasonic sensors.

Installation

1. The internal and external threads of the Air Purge Collar provide two mounting options

for 18 mm threaded-barrel sensors:

• Thread the Collar all the way onto the sensor, then mount the Collar in the mounting

bracket by its external threads, or

• Install the sensor in the mounting bracket, then thread the Collar all the way onto the

sensor.

2. Attach the air supply to the Collar by pushing a 1/8" ID air hose onto the air connection.

NOTES:

• To prevent contamination on the sensor face, use clean, dry, instrument-quality air.

• For best sensing results, teach the sensor while air is flowing.

Specifications

Housing Material

Stainless steel

Air Connection

1/8 x 10-32 stainless steel barb fitting; connects to 1.8"

ID hose

Recommended Air Flow Rate

10 liters per minute (0.35 SCFM)

Approximate Input Pressure

0.7 psi

����������������������

���������������

����������������

�����������������

��������������������

������������������

����������������

����������������

�������������������

�������������

�������������

���������������������

������

���������������