Banner U-GAGE ULTRA-BEAM Series User Manual

Page 5

3) Based on your choice in step 1, follow the appropriate adjustment procedure below:

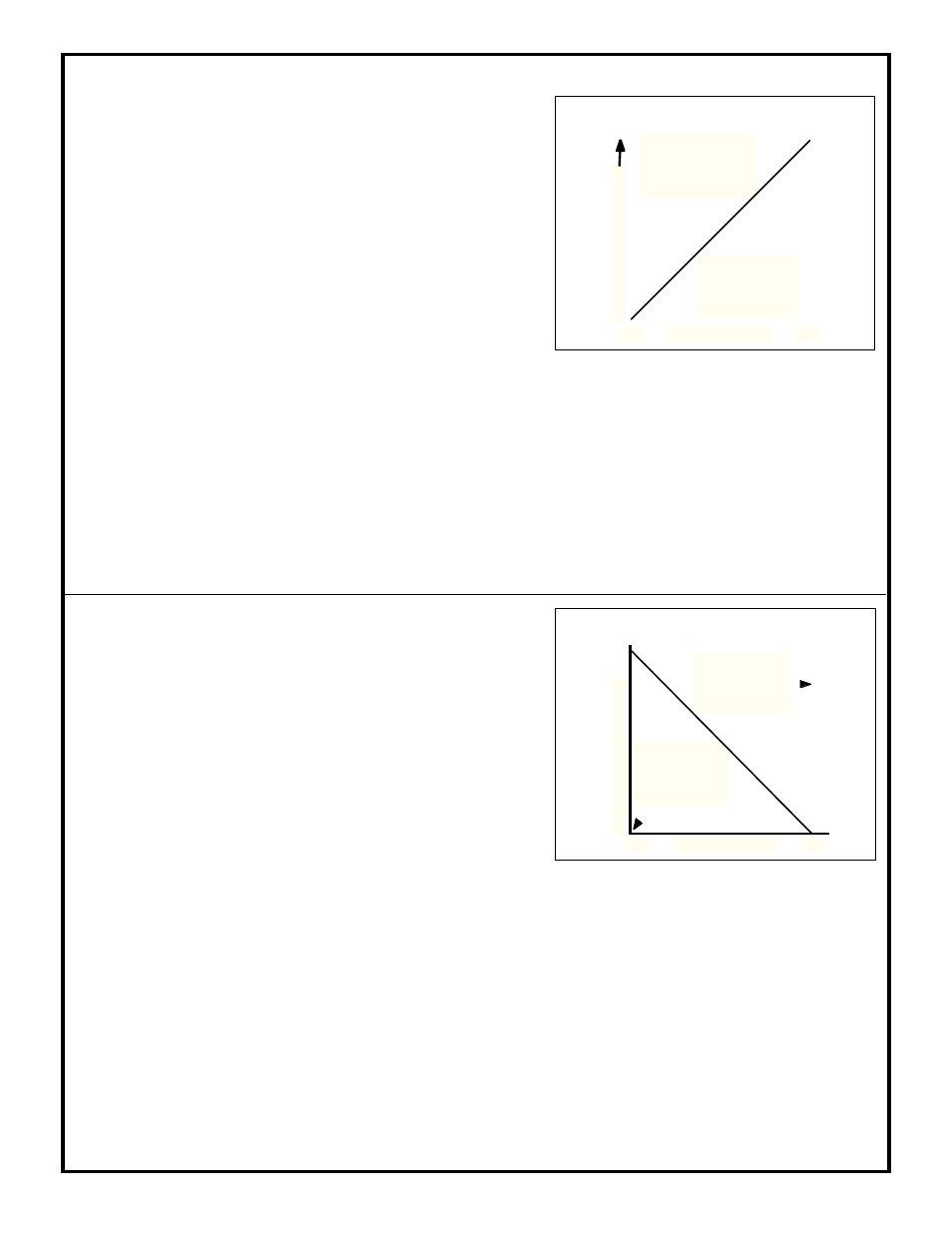

FIGURE H: Example; 5' deep window, positive slope

a) Adjustment procedure for positive slope analog output

1) Make sure that the slope select jumper clip behind the front panel of the sensor

is set for positive slope (see figure G). Remove the nylon screws covering the NULL

and SPAN controls.

2) Connect the 0 to 20mA dc sinking output of the ULTRA-BEAM to a milliammeter

(or the 0 to +10V dc sourcing output to a voltmeter) or to another instrument to be

used for readout, as shown in Figures J, K, L, and M. Connect the sensor's power

supply wires to an appropriate power supply. Double-check the connections and

switch on the power. If the sensor is receiving power, a ticking noise will be heard

from the sensor.

3) Positive slope means that the analog value of the sinking or sourcing output

increases as sensor-to-object distance increases, and decreases as that distance

decreases. The minimum and maximum current or voltage limits can be placed to

define a sensing window 12" to 18'4" deep anywhere within the 20" to 20' overall

sensor range. In the example at the right, a 5' deep window has been placed with its

near edge at 10' and its far edge at 15'. The NULL control sets the position of the

near (minimum current or voltage) end of the slope; the SPAN control sets the

position of the far (maximum current or voltage) end of the slope.

4) Set your own sensing window as follows:

a) With a target object at the near end of the window, adjust the NULL control to

just obtain a reading of 0.0mA (or your instrument's minimum current require-

ment) or 0.0V dc (or your instrument's minimum voltage requirement) on the

readout instrument. The red LED on top of the sensor should pulse in proportion

to the analog output. (If the NULL control is set for 0.0mA or 0.0V dc, there will

be no pulsing.) Remove the target.

b) Place the target at the far end of the window. Adjust the SPAN control for a

reading of 20mA (or your instrument's maximum current requirement) or +10V

dc (or your instrument's maximum voltage requirement) on the readout instru-

ment. The LED indicator should pulse at a rate propor-

tional to the analog output. Remove the target.

c) Confirm your settings by reintroducing the target at the

near edge of the sensing window. Move the target outward

in steps along the sensing axis. The analog output should

increase proportionately beginning with its set minimum,

and reach it's set maximum at the far edge of the sensing

window, at which point the LED indicator should again

pulse at its highest rate.

APPLICATION NOTE: with the sensor set for positive

slope, the sensing window may be easily shifted along the

sensing axis by moving the NULL setting. The depth of

the window will remain constant.

Max. output at 15';

set by SPAN control;

corresponds to

maximum current or

voltage output

Sensing Window

10ft

15ft

Min. output at 10';

set by NULL control;

corresponds to minimum

current or voltage

output

A

na

log Ou

tpu

t In

crease

s

b) Adjustment procedure for negative slope analog output

FIGURE I: Example; 5' deep window, negative slope

Min. output at 15';

set by SPAN control;

corresponds to

minimum current or

voltage output

Max. output at 10';

set by NULL control;

corresponds to

maximum current or

voltage output

A

na

log Ou

tpu

t In

crease

s

Sensing Window

10ft

15ft

a) With a target object at the near end of the window, adjust the NULL control to

just obtain a reading of 20mA (or your instrument's maximum current require-

ment) or +10V dc (or your instrument's maximum voltage requirement) on the

readout instrument. The red LED on top of the sensor should pulse in proportion

to the analog output. Remove the target.

b) Place the target at the far end of the window. Adjust the SPAN control for a

reading of 0.0mA (or your instrument's minimum current requirement) or 0.0V dc

(or your instrument's minimum voltage requirement) on the readout instrument.

1) Make sure that the slope select jumper clip behind the front panel of the sensor

is set for negative slope (see figure G). Remove the nylon screws covering the NULL

and SPAN controls.

2) Connect the 0 to 20mA dc sinking output of the ULTRA-BEAM to a milliammeter

(or the 0 to +10V dc sourcing output to a voltmeter) or to another instrument to be

used for readout, as shown in Figures J, K, L, and M. Connect the sensor's power

supply wires to an appropriate power supply. Double-check the connections and

switch on the power. If the sensor is receiving power, a ticking noise will be heard

from the sensor.

3) Negative slope means that the analog value of the sinking or sourcing output

decreases as sensor-to-object distance increases, and increases as that distance

decreases. The minimum and maximum current or voltage limits can be placed to

define a sensing window 12" to 18'4" deep anywhere within the overall 20" to 20'

sensor range. In the example at the right, a 5' deep window has been placed with its

near edge at 10' and its far edge at 15'. The NULL control sets the position of the

near (maximum current or voltage) end of the slope; the SPAN control sets the

position of the far (minimum current or voltage) end of the slope.

4) Set your own sensing window as follows:

The LED indicator should pulse at a rate proportional to

the analog output. (If the SPAN control is set for 0.0mA

or 0.0V dc, there will be no pulsing.) Return the target to

the near end of the window (same position as in step "a")

and "fine-tune" the NULL setting by repeating step "a".

d) Confirm your settings by reintroducing the target at the

far edge of the sensing window. Move the target inward in

steps along the sensing axis. The analog output should

increase proportionately beginning with its set minimum,

and reach it's set maximum at the near edge of the sensing

window, at which point the LED indicator should again

pulse at its highest rate.