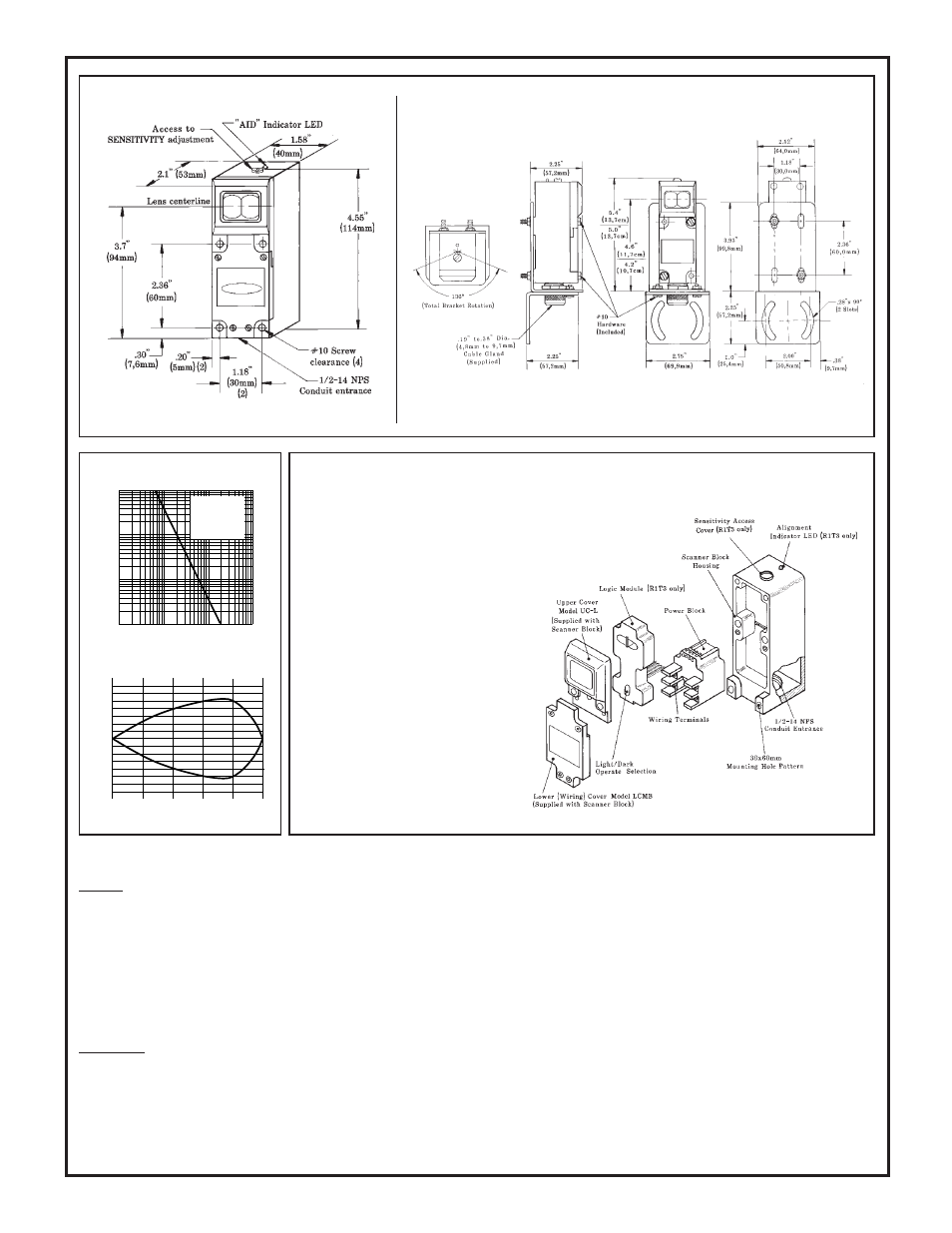

Dimensions with smbls 3-axis mounting bracket, Spare parts identification, Wiring – Banner MULTI-BEAM Series User Manual

Page 2: Alignment

Then, while holding the receiver and watching its alignment indicator

LED, move the receiver up-down and left-right, including angular posi-

tion, to locate the center of the beam. The center of the beam corre-

sponds to the strongest received signal level (fastest receiver LED

indicator pulse rate).

If the sensing area is large, reduce the sensitivity of the receiver (remove

the white nylon screw and turn the control counterclockwise) to shrink the

area. Note that this is a 15-turn control. If the emitter-receiver distance

will change during use, perform the alignment at the greatest expected

separation distance. Mount the receiver securely in the center of the beam,

and increase the

SENSITIVITY

control to maximum (15 or more full turns

fully clockwise).

Final checkout: The red LED indicator on the R1T3 receiver should be

"on" with power applied to correctly aligned units, and should go "off"

when current is applied to the modulator input (terminal #3) of the EM3T-

1M transmitter.

The light/dark operate selection jumper on the R1T3's logic module

reverses the polarity of the receiver's data stream output.

Wiring

System power: Power the sensors with 10-30V dc at terminals #1 and

#2 of each power block, observing polarity. Total current requirement is

130 mA per sensor pair, exclusive of load.

Emitter gate input: Install a suitable series resistor to limit current to 10-

30 mA. Observe polarity when connecting the gating signal.

Receiver output: The output of the receiver at terminal #3 can sink up to

250 mA at 10-30V dc. If a current sourcing output is required, substitute

power block model PBP, or assembled receiver model R1P3.

Alignment

Reliable operation of the MULTI-BEAM Optical Data

Transmitter System requires the maintenance of alignment between the

transmitter and receiver units. The model SMBLS 3-axis mounting

bracket (see above) is recommended for ease and reliability of alignment.

After all wiring has been completed and checked, align the optical data

transmitter system components. First, mount the emitter in place. Apply

power to both units. Align the units to each other as best you can "by eye".

Installation and Alignment

Dimensions, R1T3 Receiver*

*EM3T-1M dimensions identical, except no indicator LED or

SENSITIVITY adjustment.

Banner Engineering Corp. 9714 Tenth Ave. No. Minneapolis, MN 55441 Telephone: (612) 544-3164 FAX (applications): (612) 544-

3573

Dimensions with SMBLS 3-axis Mounting Bracket

Excess Gain Curve

Beam Pattern

40

0

0

I

N

C

H

E

S

OPPOSED DISTANCE--FEET

80

120

160

200

20

40

60

20

40

60

10

1

DISTANCE

100

1000

1 FT

10 FT

100 FT

1000FT

Excess Gain,

MULTI-BEAM

Optical Data

Transmitter

System

E

X

C

E

S

S

G

A

I

N

I

Spare Parts Identification

The modular parts of the Optical Data Trans-

mitter System may be ordered individually.

R1T3 Receiver:

SBR1 Scanner Block (includes covers)

UC-L upper cover (includes lens)

LCMB lower cover (includes screws)

PBT* 10-30V dc Power Block with

sinking (NPN) output

LM3 Logic Module (light or dark operate)

*For sourcing (PNP) output, substitute power

block model PBP.

EM3T-1M Emitter:

SBEM3 Scanner Block (includes covers)

UC-L upper cover (includes lens)

LCMB lower cover (includes screws)

PBT-1M 10-30V dc Power Block with

opticaly-coupled emitter gate.

NOTES: Logic module not required for

emitter. Emitter scanner block connects to

emitter power block via 4-pin connector sup-

plied with the scanner block.