Troubleshooting – Metrohm 739 Exchange unit User Manual

Page 40

8. Troubleshooting

40

6.3013.XXX and 6.3014.XXX Exchange Units, 8.110.1346

8. Troubleshooting

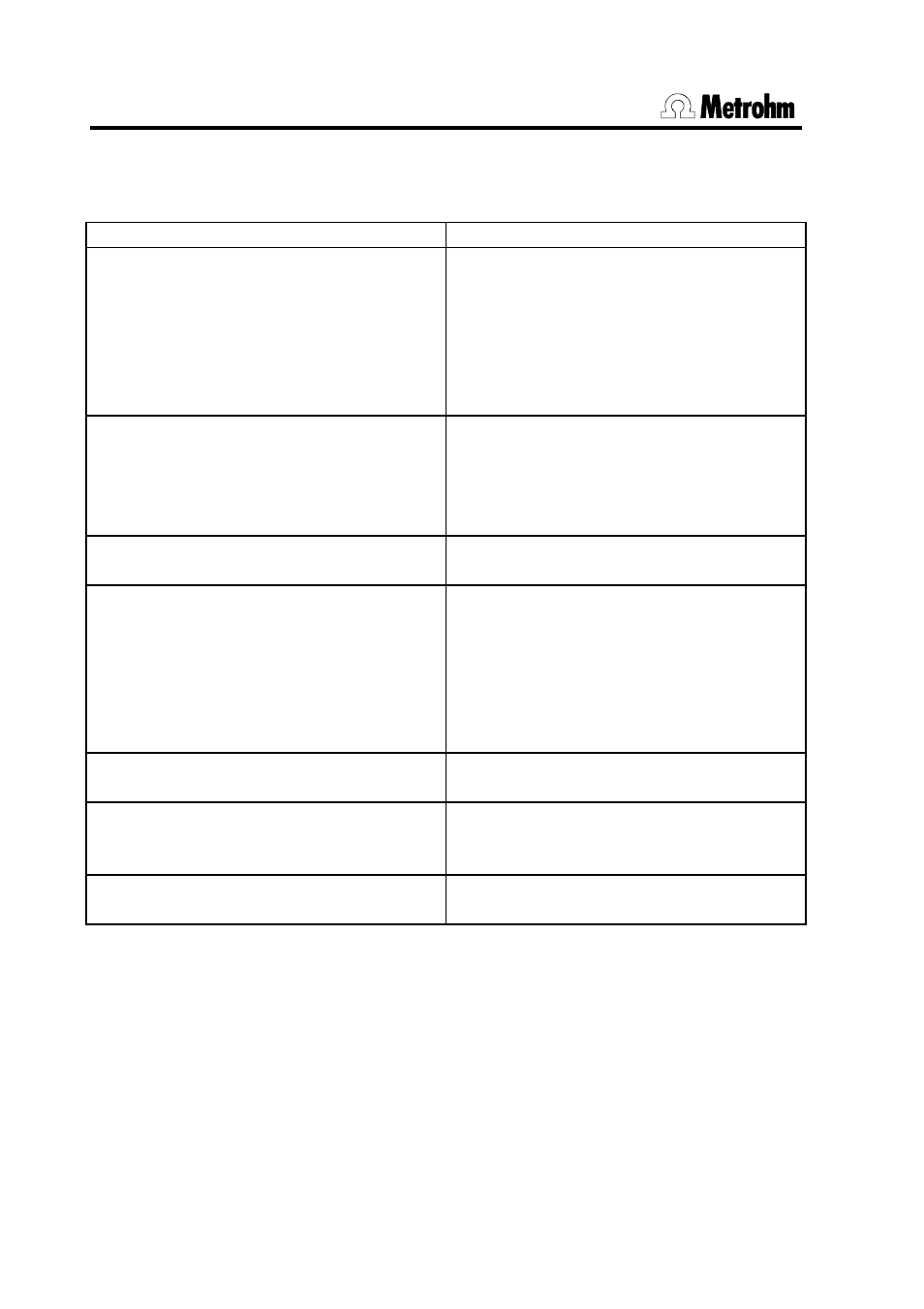

Problem

Remedial action

Air bubbles are aspirated.

– Is there sufficient reagent in the

bottle? (The aspirating tube has to

be immersed.) If necessary deaer-

ate reagent.

– Tighten all tubing connections.

– Clean stopcock, see section 4, if

necessary replace it.

Cylinder can not be filled without air

bubbles.

– Small air bubbles do not disturb,

see section 1.

– Keep glass cylinder and leading

edge of piston free of grease.

– Deaerate reagent if necessary.

Buret tip is blocked.

– Soak in appropriate solvent. Store

buret tip in solvent, see section 1.

Dosed volume is not correct.

– Carry out test according to Appli-

cation Bulletin No. 238.

– Check that there is no liquid at the

tubing connections or at the stop-

cock.

– Change glass cylinder and if nec-

essary piston.

"Piston" is leaking. There is liquid

below the piston.

– Change glass cylinder and if nec-

essary piston.

Stopcock is blocked/leaking.

– Clean stopcock. Take care not to

have any solids in the threaded

holes, see section 4.

Stopcock can not be turned.

– Clean stopcock, see section 4.

– Use PCTFE/PTFE stopcock.