2 adjuster mechanism inspection – Bendix Commercial Vehicle Systems ADB22X-V Air Disc Brakes User Manual

Page 11

11

4.2 ADJUSTER MECHANISM INSPECTION

CAUTION: Follow all safe maintenance practices.

Aside from the normal maintenance schedule, the

adjuster mechanism inspection that follows is also

carried out when the Caliper Movement Test (4.1) fi nds

that the running clearance is too small or too large.

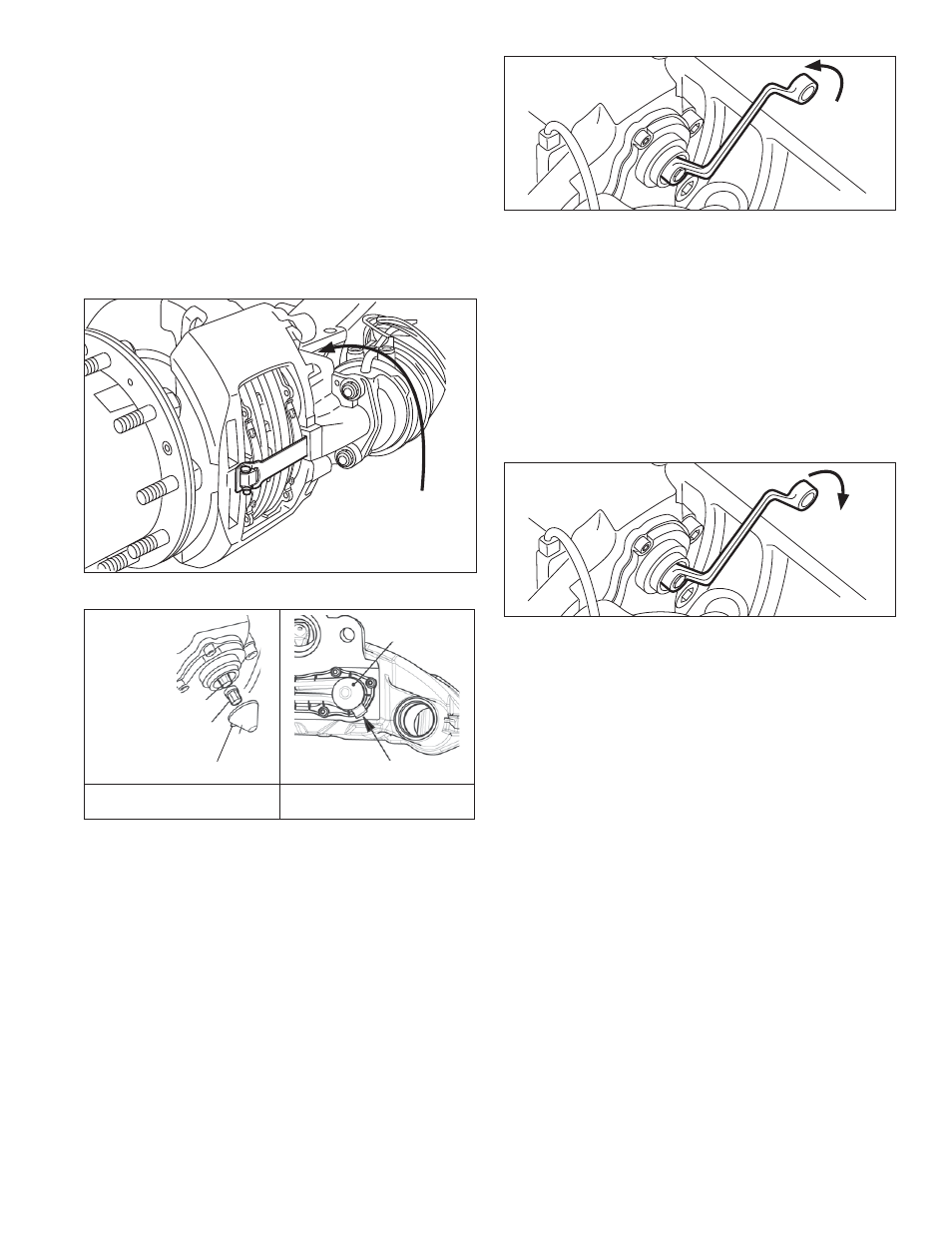

4.2.1 With the spring brake released (or caged), remove

the adjuster cap (37) using the tab, taking care not

to move the shear adapter (61). Note: One of two

styles of adjuster cap (stamped metal or plastic

adjuster cap) may be used.

Adjuster Cap

Location

FIGURE 17 - ADJUSTER CAP LOCATION

61 Adapter

23 Adjuster

37

Cap

Tab

Tab

37

Cap

FIGURE 18 - EXPLODED VIEW

OF ADJUSTER AND ADAPTER

FIGURE 19 - CAP INSTALLED:

TAB LOCATION

For illustration purposes, the exploded view (Figure 18)

shows the adjuster (23) and shear adapter (61) separated.

When using the adjuster mechanism, always have the

shear adapter installed on the adjuster.

4.2.2 Using a 10 mm. six-point box wrench, turn the Shear

Adapter (61)

counter-clockwise and listen for

the sound of 3 clicks as the mechanism backs-off

(increases) the running clearance. Note: Do not

use an open-ended wrench as this may damage

the adapter. See Figure 20.

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent excessive

torque from being applied to the adjuster. The shear

adapter will fail (by breaking) if too much torque is

applied.

FIGURE 20 - BACKING-OFF (INCREASING) THE RUNNING

CLEARANCE

If the shear adapter fails, you may attempt a second time

with a new (unused) shear adapter.

Note: Always double-check that the spring brake is released

(where applicable) if a shear adapter fails; if this step was

missed, the shear adapter will break off, and it may appear

that the caliper is seized.

In cases where a second failure of the shear adapter

confi rms that the adjustment mechanism is seized, the

caliper must be replaced.

FIGURE 21 - APPLYING MODERATE APPLICATIONS OF THE

BRAKES: THE WRENCH MOVES CLOCKWISE AS THE RUNNING

CLEARANCE IS DIMINISHED

4.2.3 Where the adjuster mechanism is able to be backed-

off normally, position a box-end wrench on the shear

adapter so that it can turn clockwise freely without

coming into contact with parts of the vehicle (See

Figure 21). Make fi ve to ten moderate applications

of the brakes [at about 30 psi (2 Bar)], and observe

that the box-end wrench or socket should turn

clockwise in small increments.

NOTE: As the number of applications increases,

the turning movement will decrease (as the brake

reaches its normal calibration point).

If the box-end wrench does not: (a) turn at all; (b) turns only

with the fi rst application; or (c) turns forward and backward

with every application, the automatic adjuster has failed and

the caliper/carrier assembly must be replaced.

After completing these wheel-off tests, Bendix recommends

installing a new adjuster cap (lightly greased using white,

lithium-based grease) when returning the brake to service.

Ensure that the tab is in the position shown in Figure 19.