Bendix Commercial Vehicle Systems ADB22X-V Air Disc Brakes User Manual

Page 10

10

Section Four

Section Page

4.0

Wheel-Off Inspections . . . . . . 10

4.1

Caliper Movement Test . . . . . . 10

4.2

Adjuster Mechanism Inspection . . . 11

4.3-4.4 Brake Pads and Rotors . . . . . 12-14

4.3

Inspect the Brake Pads . . . . . . 12

4.4

Inspect the Rotor . . . . . . . 13-14

4.4.3 Machining (Grinding or Turning) Rotors

14

4.5

Guide Pin Bearing Inspection . . . 14-15

4.6

Tappet & Boot Assembly Inspection . . 15

4.0 WHEEL-OFF INSPECTIONS

CAUTION: During these inspections, follow all safe

maintenance practices, including those on page

two of this service manual. Also, follow the vehicle

manufacturer’s recommendations. When working on

foundation brakes, be sure that the vehicle is on level

ground, that the vehicle is parked by other means

than the foundation brakes, and that the wheels are

chocked.

4.0.1 Wheel Removal and Re-Installation

Refer to the vehicle manufacturer’s recommendations for

removing the wheel.

Note: When removing the wheel, inspect fi rst to see that

there is no contact between the caliper and axle, vehicle,

chassis sections or carrier, etc. that may be impeding the

free movement of the caliper.

WARNING: Not all wheels and valve stems are

compatible with Bendix Air Disc Brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid risk of valve stem shear and

other compatibility issues. After re-installing a wheel

according to the vehicle manufacturer’s recommendations,

please ensure that there is suffi cient clearance between

the tire infl ation valve stem, the caliper and the wheel rim,

to avoid damage.

SECTION FOUR: WHEEL-OFF MAINTENANCE INSPECTIONS

4.1 CALIPER MOVEMENT TEST

CAUTION: Follow all safe maintenance practices.

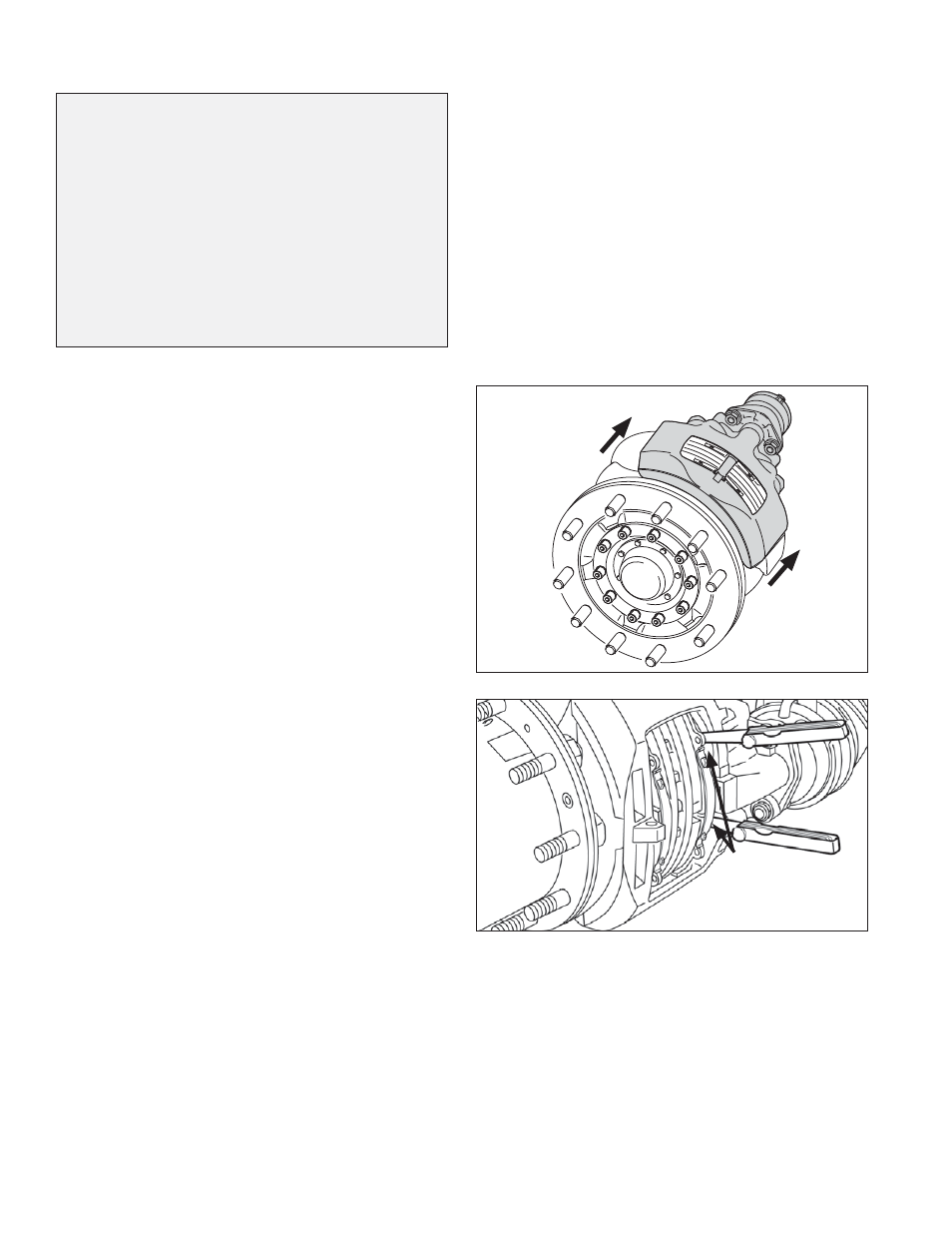

Remove the wheel. With the spring brakes released or

caged, push the caliper assembly inboard on its guide pins.

Note: To fully release the spring brakes, assure that the

air system pressure is at least 90 PSI. Using a suitable

tool (for example a large fl at-blade screwdriver), press the

inboard pad (12) away from the tappets. Check that there

is no dirt, etc. in the gap, and clean if necessary. Then use

two long-blade feeler gauges to measure over the whole

tappet surface the gap between them and the inboard pad

backplate. (See Figure 16.) The gap should be between

0.024 in. (0.6 mm) and 0.043 in. (1.1 mm).

If the gap is

within the range given, the test is complete.

Pull

Caliper

Inboard

FIGURE 15 - PULL CALIPER INBOARD

Check the clearance at

both tappets simultaneously:

0.024 in. to 0.043 in.

(0.6 mm. to 1.1 mm.)

FIGURE 16 - RUNNING CLEARANCE CHECK

CAUTION: If the clearance is too wide, there is a

danger of brake failure. If the clearance is too small,

or if there is no gap at all, there is a danger of the brake

overheating. These conditions must be corrected

before returning the vehicle to service.

For further investigation, where there is some gap, go to

Section 4.2 and check the adjuster mechanism. Where

there is no movement at all (and so no gap to measure),

go to Section 4.5 “Guide Pin Inspection.”