Bendix Commercial Vehicle Systems GEN 5 ABS User Manual

Page 36

36

ATC Valve Removal

CAUTION: Block wheels before beginning this procedure.

Follow all standard safety procedures, outlined by, but not

limited to, the General Precautions listed on page 13 of

this document.

1. Disconnect the wiring connector from the ATC valve.

2. Disconnect the air lines from the supply (port 1) and

delivery port (port 2) and treadle (port 3) of the ATC

valve.

3. Disconnect the valve mounting fasteners, and remove

the valve.

Installation

1. Install the ATC valve. Torque fasteners to manufacturers

specification.

2. Connect Air lines supply (port 1) delivery port (port 2)

and treadle (port 3) of the ATC valve.

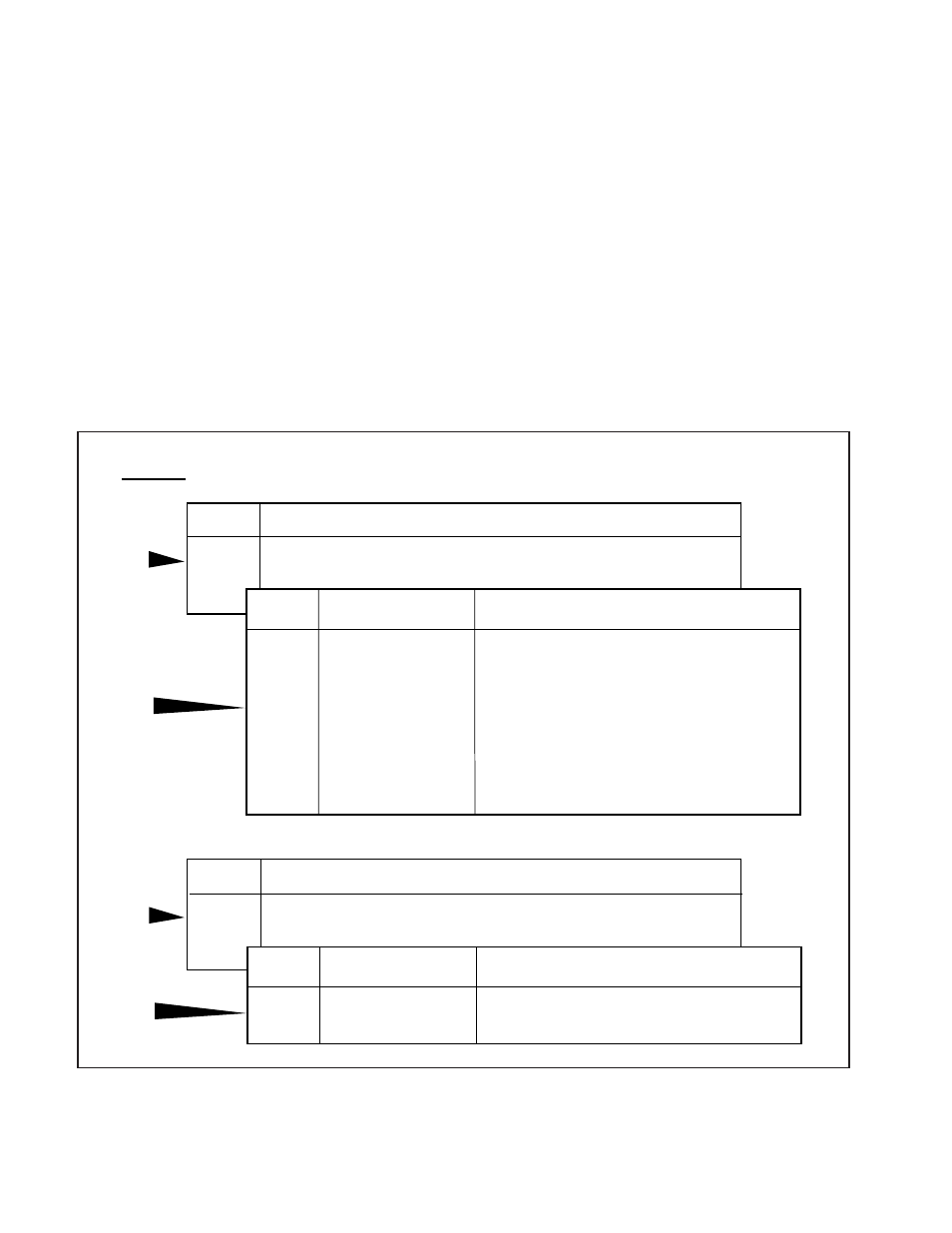

FIGURE 37 - System and ECU Diagnostic Trouble Codes Troubleshooting Guide

1st

1st

2nd

1.5 Sec.

Pause

Location

ECU, Engine Interface

Action

Refer to electrical schematic. Check for proper connection of data link to ECU.

Verify that polarity is correct.

Unplug connector at ECU. There should be a voltage between 0 and 2.5 volts on

J1922/J1939 (–) and a voltage between 2.5 and 5 volts on J1922/J1939 (+).

If vehicle is not equipped with J1922/J1939 engine link, use diagnostic tool to

reconfigure ECU.

Condition

No connection found to engine data

link (J1922/J1939).

Flashes

14

Blink Code

Sequence

2nd

1.5 Sec.

Pause

Location

ECU

Action

If fault cannot be cleared, replace ECU.

Condition

ECU Internal Fault

Flashes

15

Flashes

1–11

Flashes

12

3. Install the wiring connector to the ATC valve.

4. Test the installation.

• Traction Control Valve – Leak Test:

Make and hold brake application. No audible air leaks are

permitted.

• Traction Control Valve Component Test with Hand-

Held Diagnostic Tool:

Select Traction Control Valve

Verify Traction control light operation

Drive the vehicle and verify ABS indicator lamp operates

properly.

CAUTION: Do not start and engage the transmission with

one wheel raised from the floor. With ATC, power will go to

the wheel on the floor and cause the vehicle to move. See

page 20 to disable ATC for dyno testing.