Bendix Commercial Vehicle Systems GEN 5 ABS User Manual

Page 34

34

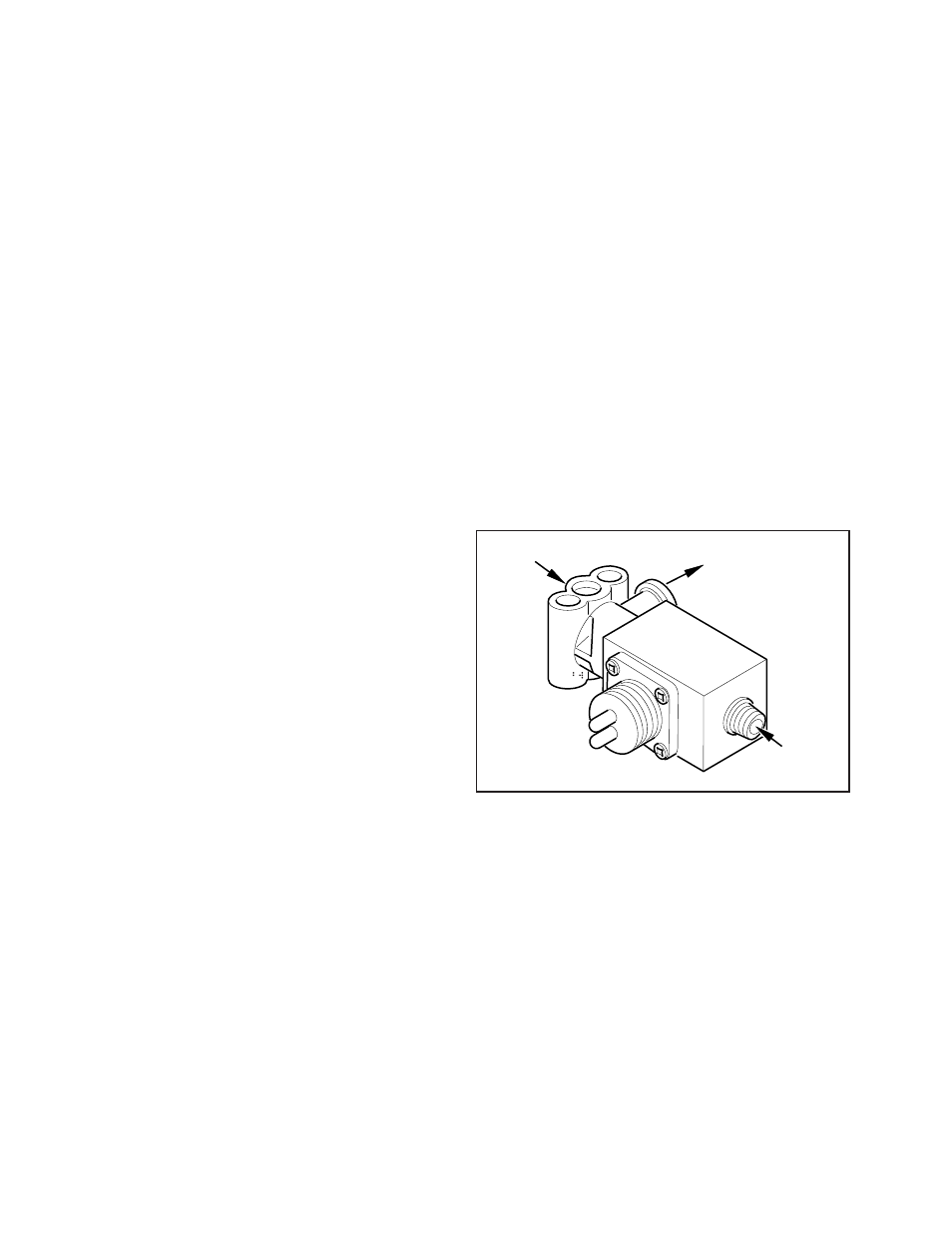

FIGURE 34 - ATC Valve

Performance Test of the Relay Valve

CAUTION: Block wheels before beginning this procedure.

Follow all standard safety procedures, outlined by, but not

limited to, the General Precautions listed on page 13 of

this document.

1. Park vehicle on level surface and block wheels.

2. Release parking brake and fully charge the air system

(governor cut out point).

3. Turn the engine OFF. Apply the service brake several

times, then hold and check for prompt brake air chamber

application and release at all wheels.

4. Apply brake, then hold. Coat outside of relay valve

(where cover joins body) and connection between

modulator valve and relay valve with a soap solution.

No leakage is permitted.

5. If a sluggish response is noted at all wheels, inspect for

kinked or obstructed air line leading to or from valve.

6. Increase system air pressure to governor cutoff. With

the brakes released, coat exhaust port of relay valve

with a soap solution. Leakage of a 1" bubble in 5

seconds is permissible.

7. Depress foot valve and keep depressed. Coat exhaust

port with a soap solution. Leakage of a 1" bubble in 3

seconds is permissible.

Automatic Traction Control (ATC) Valve

Troubleshooting

The following ATC troubleshooting pages provide the basic

information necessary to: identify the diagnostic trouble

code; locate the problem; review the possible cause(s);

select the correct solution and utilize proper repair

procedures.

Follow the steps listed below to locate and correct ATC

problems.

1. Access active diagnostic trouble code(s) using either

the Blink Code procedure or the hand-held tester

procedure.

2. Lookup the code description, the possible causes and

the repair procedures provided in this section.

3. Perform the recommended repair procedures.

4. After the repairs are completed, clear all codes and

check for any additional codes.

Whether the ATC Valve is used as a stand-alone valve as

shown in Figure 34 or is integrated into the cover of a relay

valve as shown in Figure 33, the troubleshooting procedure

is the same.

(3) Treadle

(1) Tank Air

(2) Relay valve

control line