Bendix Commercial Vehicle Systems GEN 5 ABS User Manual

Page 2

2

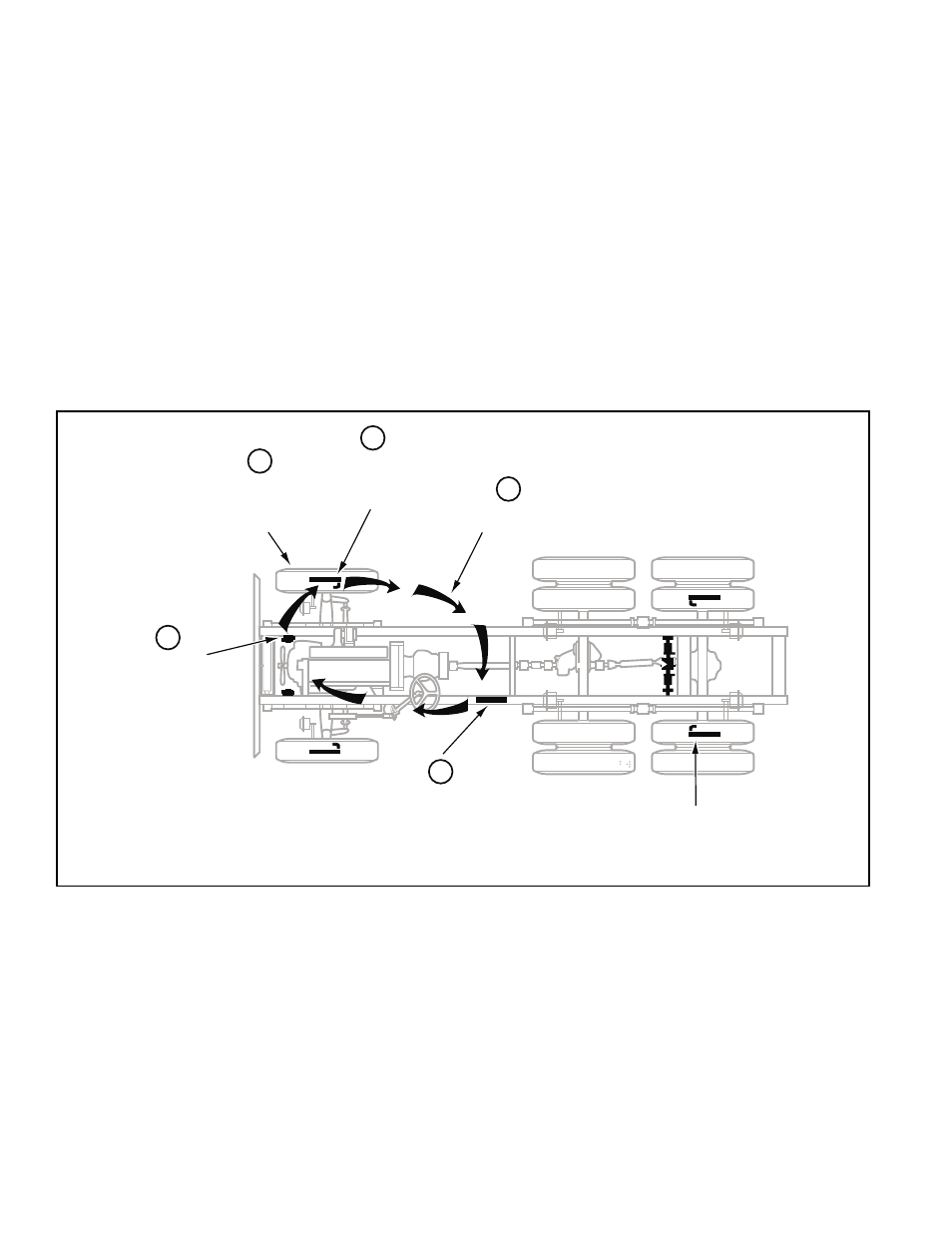

FIGURE 2 - Overview of ABS Operation

ANTILOCK BRAKING SYSTEM (ABS)

ABS-controlled braking ensures optimum vehicle stability

while minimizing the stopping distance. During vehicle

operation, the ABS Electronic Control Unit (ECU)

continuously monitors all wheel speed sensors. Data input

from the wheel speed sensors allows the ECU to:

•

Detect impending wheel lock.

•

Maintain optimum wheel slip during braking.

•

Maximize vehicle stability while maintaining braking

effectiveness.

ABS Operation

The ABS controls braking by operating the Pressure

Modulator Valves. The ECU makes a new assessment of

conditions and updates the control signal to the pressure

modulator valves at the rate of 100 times per second.

Speed sensors

monitor wheel

rotation

1

Speed signal

to ECU

Electronic Control Unit (ECU)

interprets speed signals

and activates valves

Hold and release

solenoids control

air pressure in the

brake chambers

Sensors on

all configured wheels

signal status to ECU

Braking force

remains at

optimum level

2

3

4

5

When inactive, the pressure modulator valves provide

straight-through-passages for supply air to the brake

chambers. During ABS operation (an ABS “event”), the

control unit operates the valves to override the supply of

air to the chambers. During an ABS release, supply air is

held off while the chambers are vented to the atmosphere.

In hold mode, supply air is held off and chamber air is held

constant. When required, air is applied to the chamber at

a controlled rate by modulating the hold side of the

modulator valve.

The ABS system itself does not apply additional braking

power. Rather, the purpose of ABS is to limit brake torque

to prevent locking that results in loss of lateral stability and

increased stopping distances. Cautious driving practices

such as maintaining adequate distances from the vehicle

ahead are still essential to safe vehicle operation.